I, like others, am looking at the Ace micro brewery as an option but it doesnt come with a wort chiller. So I've done a look around and have some questions. It may also influence my decision. For this thread I am not looking for info on no chill brewing but if you do this and want to comment feel free as others may be interested.

First, it looks like counter flow chillers are a lot quicker. I have seen things which suggest a counter flow chiller is quicker than a counter flow chiller by some amount. I've read that an immersion chiller will take 40 mins and counter flow 10 mins, thats quite a difference.

What type of chiller do you have and how long does it take for a standard 23l wort to be cooled to pitching temperature. Size/rating is also relevant here and also how its used, e.g. if using an immersion chiller do you use the pump to circulate the wort?

The other thing that may influence which I go for is cleaning. Obviously an immersion chiller only needs the outside cleaning as thats what comes into contact with the beer. What about a counter flow chiller? Is running steraliser through sufficient to keep brews sterile?

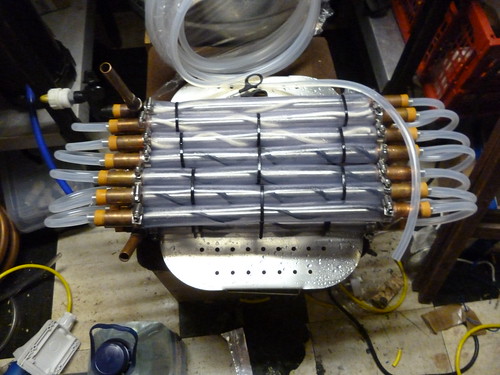

If I get the Ace I'm considering a plate chiller like this

http://www.the-home-brew-shop.co.uk/acatalog/CounterFlow_Wort_Chiller.html

or this

https://www.manomano.co.uk/heat-exc...plates-max-66-kw-plate-heat-exchanger-3214341

Anyone know if these are any good?

First, it looks like counter flow chillers are a lot quicker. I have seen things which suggest a counter flow chiller is quicker than a counter flow chiller by some amount. I've read that an immersion chiller will take 40 mins and counter flow 10 mins, thats quite a difference.

What type of chiller do you have and how long does it take for a standard 23l wort to be cooled to pitching temperature. Size/rating is also relevant here and also how its used, e.g. if using an immersion chiller do you use the pump to circulate the wort?

The other thing that may influence which I go for is cleaning. Obviously an immersion chiller only needs the outside cleaning as thats what comes into contact with the beer. What about a counter flow chiller? Is running steraliser through sufficient to keep brews sterile?

If I get the Ace I'm considering a plate chiller like this

http://www.the-home-brew-shop.co.uk/acatalog/CounterFlow_Wort_Chiller.html

or this

https://www.manomano.co.uk/heat-exc...plates-max-66-kw-plate-heat-exchanger-3214341

Anyone know if these are any good?