Hi!

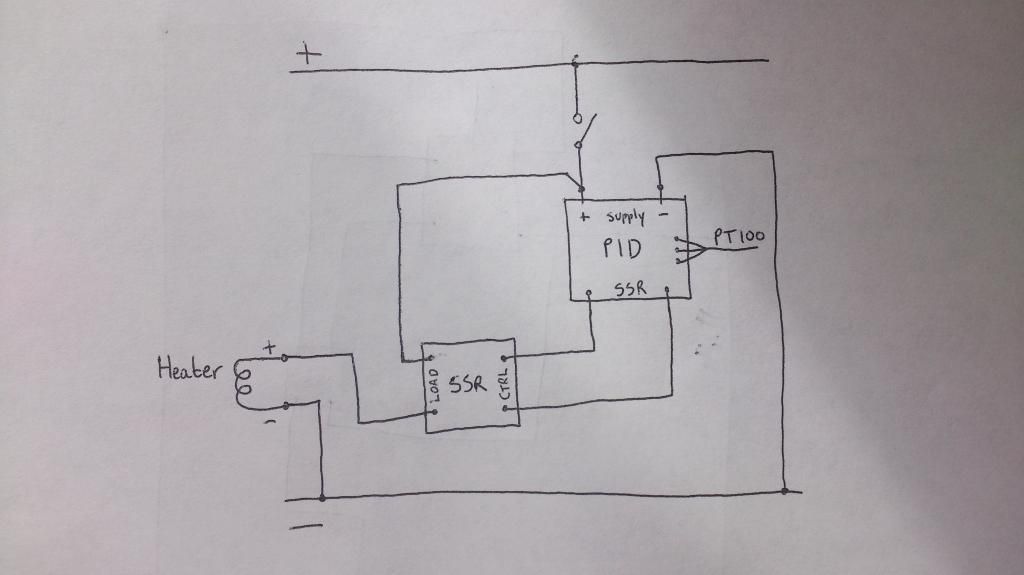

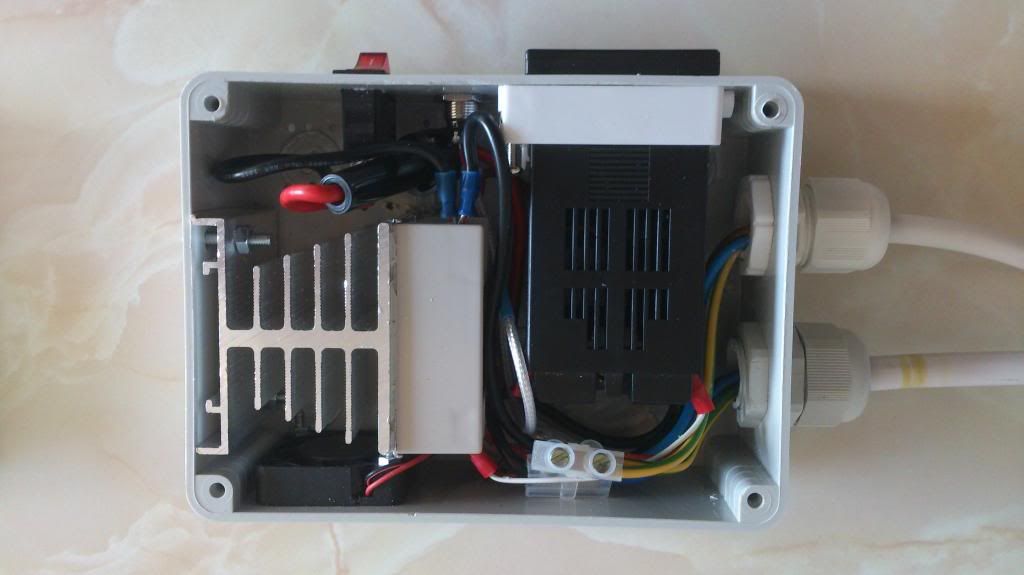

I am using the tea urn purely as a HLT. When the liquor hits strike temperature it's pumped into the mash tun through the tap (underletting) and a PID controls the temperature of the mash by heating the wort directly through the ACE boiler's concealed element; the grain sits on a false bottom and the element is dialled down with a PWM voltage regulator. A pump recirculates the wort past a temperature probe connected to the PID and back into the top of the mash tun.

I get the impression that a RIMS tube, as you show, is used by brewers using bottled gas to heat the boiler. The RIMS tube is the only electrical heater in an otherwise gas-based brewery.

I am using the tea urn purely as a HLT. When the liquor hits strike temperature it's pumped into the mash tun through the tap (underletting) and a PID controls the temperature of the mash by heating the wort directly through the ACE boiler's concealed element; the grain sits on a false bottom and the element is dialled down with a PWM voltage regulator. A pump recirculates the wort past a temperature probe connected to the PID and back into the top of the mash tun.

I get the impression that a RIMS tube, as you show, is used by brewers using bottled gas to heat the boiler. The RIMS tube is the only electrical heater in an otherwise gas-based brewery.