Mornin

What a emazing sleep! A massive meal..A few glasses of merlot, a pint of draught Amstel and 2 jagabombs..taxi home and tried a merlot...no medication! 'Good nite Vienna!'

Not the best mix of alcohol I admit...

But no hangover etc..

Ok I'm a light weight! Have to control what I drink and food etc.

Anyways.........

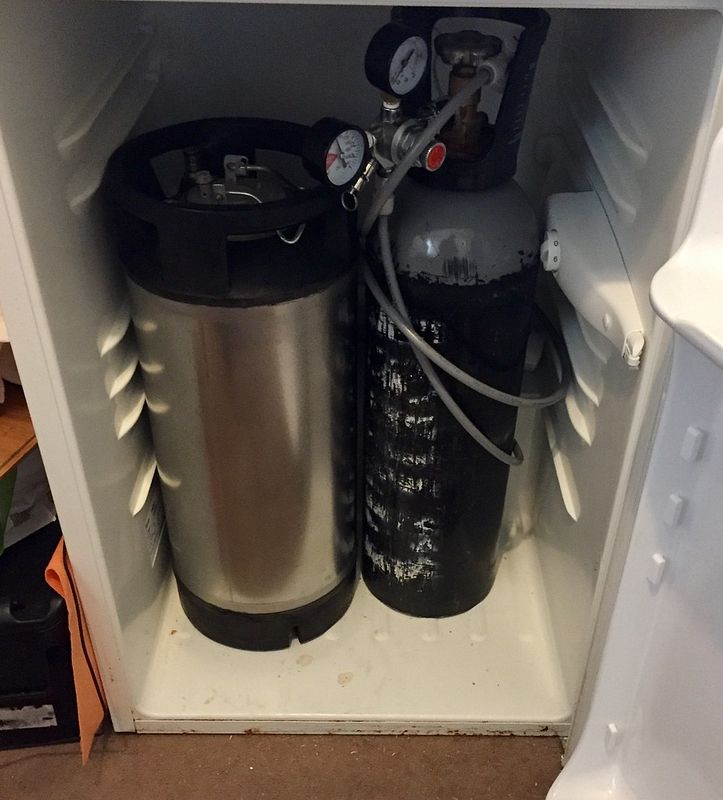

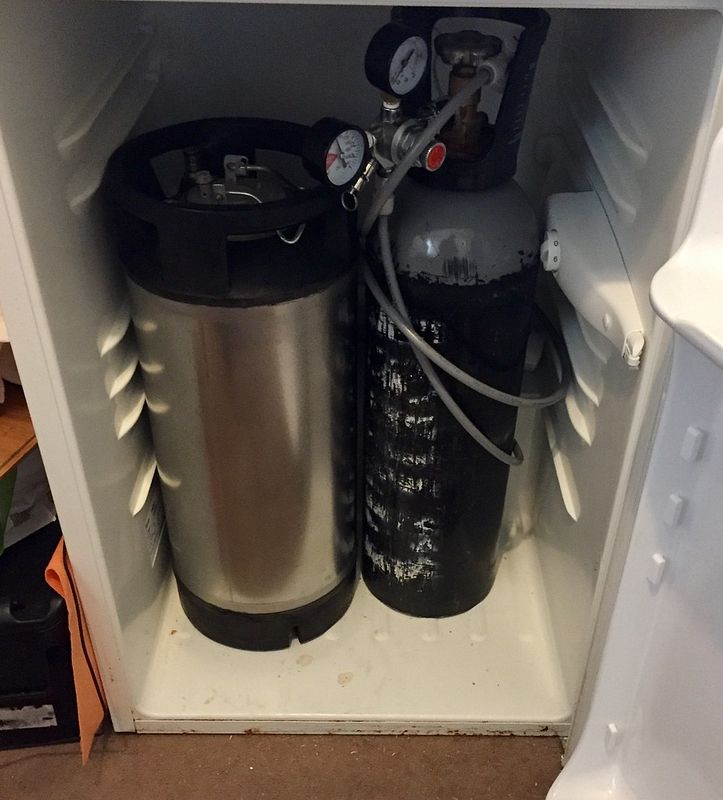

Moving on with my corni keg set up!

....................................................

Only 10l of centurial (never get the spelling right!) Brown Ale, into the cleaned n sanitized keg.

Put the fridge setting about 6C (not sure is the temp right, got confused with a thread of serving temps...??)

And left it til today.

So I've been looking on all the threads, YouTube channels....BOOM!!! my brain retention switch went!!!!!! (U know me by now...too much info overload!!)

So for safety and my peice of mind I just left it till yous guru's can nurture my brain cells into action...please & always I appreciate your help n guidance.

One thing we know is:

1. 10l brown ale.

2. No priming sugar.

3. The temp of the corni in the fridge...6.5C...what should the temp be?

4. of beer line 2m..(so far I don't know the exact length needed..(the threads working out the length, as you can imaging...went Pete Tong!)

5. Finally looked at the options of carbing the beer...at that stage!! It just went mush into overload...haha!

Like I said just sealed the keg and put into the fridge.

If you can help me the next stages..I'll write them down (in my google sheets..bloody great for my notes!)

ââ¬Â¦Ã¢â¬Â¦Ã¢â¬Â¦Ã¢â¬Â¦...........................................

Once again THINKING OUT LOUD!

I'm thinking myself what I should do! Instead of jus asking every time..

Reet!

Getting the fridge and beer upto temp...attach the gas line to XX psi..

And leave it for XX of days.

Take of the gas...purge the keg.

Attach the gas again...this time put XX psi to serve..leave XX of days.

Then check..

Is this in your field of view of what you would do?

No wonder I got fried there so much garbage out there...do this..naaa! This is the best way!! Naaaa! That wrong!! I do it this way!!! Blah blah blah!!!

AnywAys....I'm woffling on as usual..

Any suggestions and tips or just tell me I'm a complete.....

Lol