cerbera84

Well-Known Member

Hi guys,

I previously made a somewhat failed basic attempt at a switch to an eBIAB rig last year. The system was a bit of a hash together, and suffered from insufficient drainage in the grain basket. It did produce a splendid Cascade SMASH though. A few modifications were made but ultimately I gave up and went back to my 3V setup. Fast forward 12 months and I havenââ¬â¢t brewed as much as Iââ¬â¢d like, so I started giving more thought to a Grainfather-esq eBIAB rig build. I have been tinkering away in the garage and the system is ready for a brewday this weekend. Gentlemen, I present: the MaltMotherââ¢.

Untitled by Ben, on Flickr

Untitled by Ben, on Flickr

Untitled by Ben, on Flickr

Untitled by Ben, on Flickr

Untitled by Ben, on Flickr

Untitled by Ben, on Flickr

Untitled by Ben, on Flickr

Untitled by Ben, on Flickr

Untitled by Ben, on Flickr

Untitled by Ben, on Flickr

Untitled by Ben, on Flickr

Untitled by Ben, on Flickr

Untitled by Ben, on Flickr

Untitled by Ben, on Flickr

Untitled by Ben, on Flickr

Untitled by Ben, on Flickr

Untitled by Ben, on Flickr

Untitled by Ben, on Flickr

Untitled by Ben, on Flickr

Untitled by Ben, on Flickr

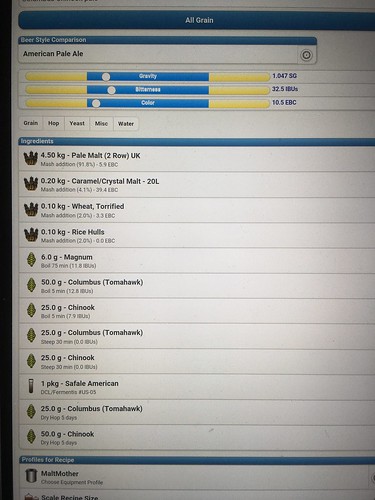

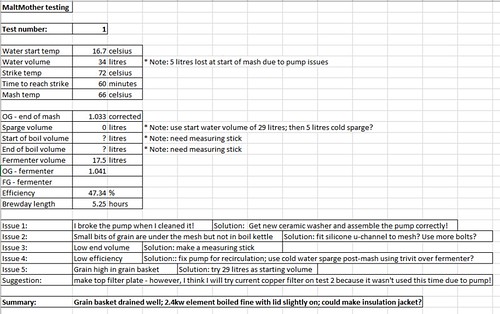

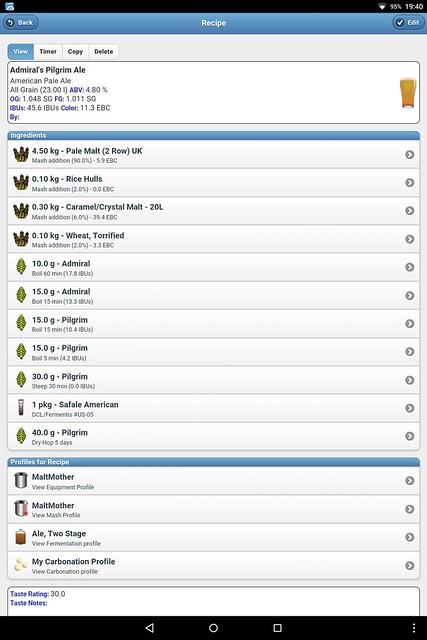

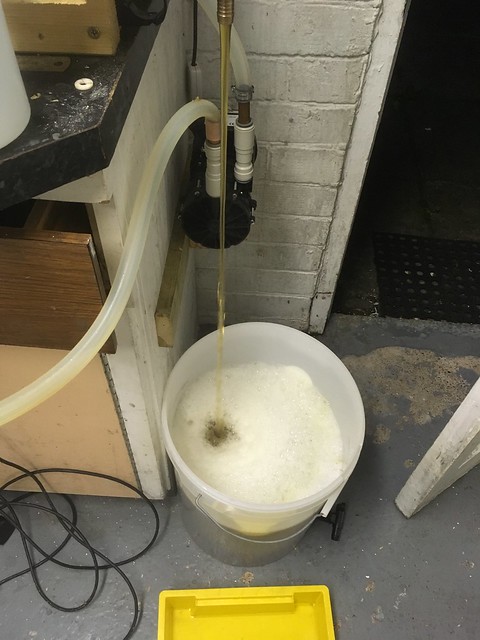

In a nutshell, I have attempted to clone a Grainfather, with the addition of a whirlpool port. This whirlpool can also be used during the continuous recirculation in the mash, which should prevent scorching from the element and also ensure an even temperature.

The grain basket is a 33 litre Bergland stock pot, with 38mm holes in the base, with a 2mm perforated SS sheet inside. It is fitted with SS legs and has a central return pipe, in case of overflow. I have adapted a 15mm to 28m copper reducer as a filter (to prevent using a top filter) �" Iââ¬â¢ll see how this works in the brewday at the weekend. The handles have been trimmed down, and now act as guides inside the larger pot. I may attempt to use these for lifting the grain basket out. I also have an IKEA SS trivit tray to rest the grain basket on post-mash. I am planning full volume BIAB so no sparge. Will use rice hulls in the bottom to try and avoid recirc problems.

The recirculation arm was made using solder ring fittings and my heat gun (in lieu of a blowtorch) �" this worked surprisingly well. I have attached silicone tubing at the moment. I had previously made a sparge fitting by drilling a brass stop end with undercut which might be reused in this project. The arm can also be used a cleaning attachment/pump out to the fermenter/drain.

The main pot is a 50 litre Bergland stock pot (which used to be my HLT). It has a pump outlet, whirlpool/drain port, temp probe and supports the recirculation arm. There are two holes currently blanked off, which I may use in the future for an internal immersion chiller. I am using a Norm pump (Flojet GP20/12) for recirculation.

The height of the central return pipe is currently set for approx. 36 litres. I am aiming for 34 litres full volume BIAB, so hopefully Iââ¬â¢m in the right ball park.

I will use my previously built control box incorporating a XMT-7100. I would like to look to add step-mashing functionality (which the XMT-7100 doesnââ¬â¢t offer) so Iââ¬â¢m open to suggestions. I have considered using a Grainfather connect unit, but will need to research further.

There are some more images on Flickr here https://www.flickr.com/gp/132217812@N06/57m35F if you wish.

Ben

I previously made a somewhat failed basic attempt at a switch to an eBIAB rig last year. The system was a bit of a hash together, and suffered from insufficient drainage in the grain basket. It did produce a splendid Cascade SMASH though. A few modifications were made but ultimately I gave up and went back to my 3V setup. Fast forward 12 months and I havenââ¬â¢t brewed as much as Iââ¬â¢d like, so I started giving more thought to a Grainfather-esq eBIAB rig build. I have been tinkering away in the garage and the system is ready for a brewday this weekend. Gentlemen, I present: the MaltMotherââ¢.

Untitled by Ben, on Flickr

Untitled by Ben, on Flickr Untitled by Ben, on Flickr

Untitled by Ben, on Flickr Untitled by Ben, on Flickr

Untitled by Ben, on Flickr Untitled by Ben, on Flickr

Untitled by Ben, on Flickr Untitled by Ben, on Flickr

Untitled by Ben, on Flickr Untitled by Ben, on Flickr

Untitled by Ben, on Flickr Untitled by Ben, on Flickr

Untitled by Ben, on Flickr Untitled by Ben, on Flickr

Untitled by Ben, on Flickr Untitled by Ben, on Flickr

Untitled by Ben, on Flickr Untitled by Ben, on Flickr

Untitled by Ben, on FlickrIn a nutshell, I have attempted to clone a Grainfather, with the addition of a whirlpool port. This whirlpool can also be used during the continuous recirculation in the mash, which should prevent scorching from the element and also ensure an even temperature.

The grain basket is a 33 litre Bergland stock pot, with 38mm holes in the base, with a 2mm perforated SS sheet inside. It is fitted with SS legs and has a central return pipe, in case of overflow. I have adapted a 15mm to 28m copper reducer as a filter (to prevent using a top filter) �" Iââ¬â¢ll see how this works in the brewday at the weekend. The handles have been trimmed down, and now act as guides inside the larger pot. I may attempt to use these for lifting the grain basket out. I also have an IKEA SS trivit tray to rest the grain basket on post-mash. I am planning full volume BIAB so no sparge. Will use rice hulls in the bottom to try and avoid recirc problems.

The recirculation arm was made using solder ring fittings and my heat gun (in lieu of a blowtorch) �" this worked surprisingly well. I have attached silicone tubing at the moment. I had previously made a sparge fitting by drilling a brass stop end with undercut which might be reused in this project. The arm can also be used a cleaning attachment/pump out to the fermenter/drain.

The main pot is a 50 litre Bergland stock pot (which used to be my HLT). It has a pump outlet, whirlpool/drain port, temp probe and supports the recirculation arm. There are two holes currently blanked off, which I may use in the future for an internal immersion chiller. I am using a Norm pump (Flojet GP20/12) for recirculation.

The height of the central return pipe is currently set for approx. 36 litres. I am aiming for 34 litres full volume BIAB, so hopefully Iââ¬â¢m in the right ball park.

I will use my previously built control box incorporating a XMT-7100. I would like to look to add step-mashing functionality (which the XMT-7100 doesnââ¬â¢t offer) so Iââ¬â¢m open to suggestions. I have considered using a Grainfather connect unit, but will need to research further.

There are some more images on Flickr here https://www.flickr.com/gp/132217812@N06/57m35F if you wish.

Ben