Hi!

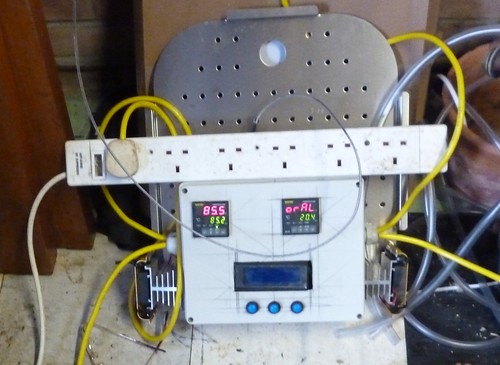

I'm about to build a controller for a recirculating mash system using two boilers and I am currently designing the control box to be permanently fixed to the wall..

I have two options open (and I have the parts to do both):

1. Mount the heatsink outside the box on an aluminium plate mounted to the rear of the box. The SSR stays inside the box but is bolted to the aluminium sheet through a hole in the side of the box. This means that the box will have to stand 5cm away from the wall, but the advantage is that I probably won't need an internal fan.

2. Mount a fan sandwiched between two sheets of perforated aluminium and mount the heatsink onto one of the aluminium sheets. This means that the fan is drawing hot air directly away from the heatsink (I will make input holes in the side of the box). However, as the height of the fan, heatsink and SSR will be almost as tall as the box itself there will be room for only two sockets on the box - the third (for the pump) will have to be on an extension wired into the system.

I have also looked at mounting the SSR and heatsink horizontally, which would allow all three sockets to be fitted, but I read that it will be less efficient at dissipating heat.

Any comments that will help?

I'm about to build a controller for a recirculating mash system using two boilers and I am currently designing the control box to be permanently fixed to the wall..

I have two options open (and I have the parts to do both):

1. Mount the heatsink outside the box on an aluminium plate mounted to the rear of the box. The SSR stays inside the box but is bolted to the aluminium sheet through a hole in the side of the box. This means that the box will have to stand 5cm away from the wall, but the advantage is that I probably won't need an internal fan.

2. Mount a fan sandwiched between two sheets of perforated aluminium and mount the heatsink onto one of the aluminium sheets. This means that the fan is drawing hot air directly away from the heatsink (I will make input holes in the side of the box). However, as the height of the fan, heatsink and SSR will be almost as tall as the box itself there will be room for only two sockets on the box - the third (for the pump) will have to be on an extension wired into the system.

I have also looked at mounting the SSR and heatsink horizontally, which would allow all three sockets to be fitted, but I read that it will be less efficient at dissipating heat.

Any comments that will help?