rpt

Brewing without a hat

This How To shows how to fit a ball valve and a hop stopper to a 40L Buffalo boiler. It doesn't require any cutting or drilling. And it's all shiny!

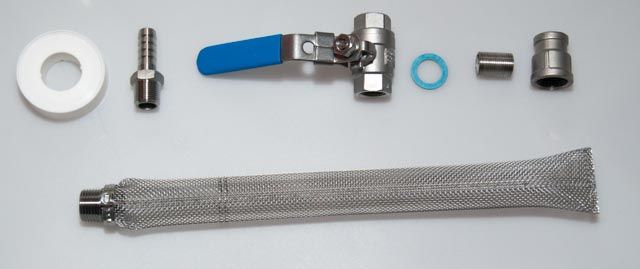

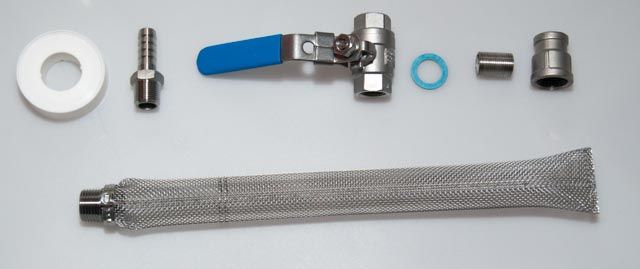

Here are the bits you need:

PTFE tape - I already had this but you can get it from many DIY shops such as Wilko or BES.

From BES:

14557 3/8" BSP TM, Stainless steel hose tail adaptor

20306 3/8" BSP Stainless steel 2-piece ball valve (I wouldn't recommend the 1-piece as it is reduced bore)

20176 3/4" Kevlar washer (yes, three quarters of an inch)

14461 3/8" BSP Stainless steel parallel nipple

14321 1/2" x 3/8" BSP Stainless steel reducing socket

From the Home Brew Shop:

846190 Bazooka 12" Large Mash / Hop Screen

I also got my 3/8" silicone tubing from here (part 400001).

And, of course, you will need a 40L manual fill Buffalo boiler. I got mine quite cheaply from the Nisbets clearance store on eBay.

Firstly, you need to remove the original tap from the boiler. It's only hand tight so it comes off without any tools.

Next, screw the parallel nipple into the ball valve and put the kevlar washer on the nipple:

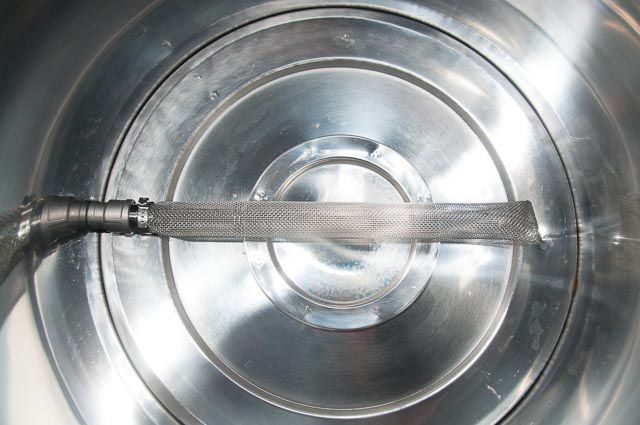

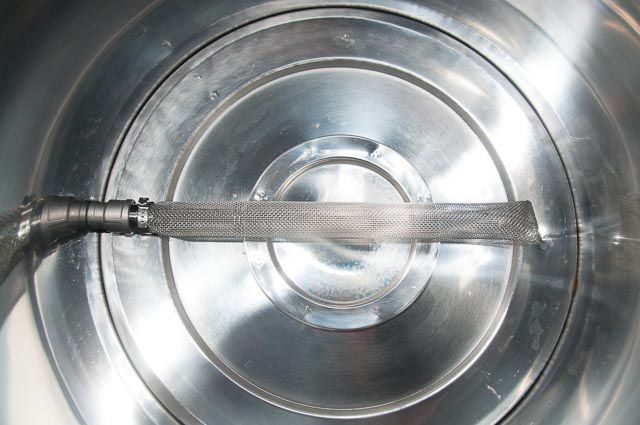

Screw the bazooka screen into the reducing socket. The male thread is taper so it doesn't screw all the way into the socket:

Put the valve and nipple through the hole on the outside of the boiler:

and screw the coupler onto the nipple on the inside of the boiler:

It's a bit fiddly to do this as you can't freely turn the hop stopper. However, it isn't too hard to do so persevere. Get it as tight as you can but with the handle at the top. Again, it only needs to be hand tight for a good seal.

Finally, wrap some PTFE tape around the male thread on the hose tale adaptor and screw it into the ball valve:

The silicone hose easily pushes onto the barb and seals perfectly.

I suggest you make sure everything is tight before you use the boiler each time.

I have done this with the 40L Buffalo boiler but it looks like it should also work with the 30L Buffalo as it is the same diameter.

Here are the bits you need:

PTFE tape - I already had this but you can get it from many DIY shops such as Wilko or BES.

From BES:

14557 3/8" BSP TM, Stainless steel hose tail adaptor

20306 3/8" BSP Stainless steel 2-piece ball valve (I wouldn't recommend the 1-piece as it is reduced bore)

20176 3/4" Kevlar washer (yes, three quarters of an inch)

14461 3/8" BSP Stainless steel parallel nipple

14321 1/2" x 3/8" BSP Stainless steel reducing socket

From the Home Brew Shop:

846190 Bazooka 12" Large Mash / Hop Screen

I also got my 3/8" silicone tubing from here (part 400001).

And, of course, you will need a 40L manual fill Buffalo boiler. I got mine quite cheaply from the Nisbets clearance store on eBay.

Firstly, you need to remove the original tap from the boiler. It's only hand tight so it comes off without any tools.

Next, screw the parallel nipple into the ball valve and put the kevlar washer on the nipple:

Screw the bazooka screen into the reducing socket. The male thread is taper so it doesn't screw all the way into the socket:

Put the valve and nipple through the hole on the outside of the boiler:

and screw the coupler onto the nipple on the inside of the boiler:

It's a bit fiddly to do this as you can't freely turn the hop stopper. However, it isn't too hard to do so persevere. Get it as tight as you can but with the handle at the top. Again, it only needs to be hand tight for a good seal.

Finally, wrap some PTFE tape around the male thread on the hose tale adaptor and screw it into the ball valve:

The silicone hose easily pushes onto the barb and seals perfectly.

I suggest you make sure everything is tight before you use the boiler each time.

I have done this with the 40L Buffalo boiler but it looks like it should also work with the 30L Buffalo as it is the same diameter.