guyb

Regular.

Well, after a few months of beavering away, I was finally ready on Monday to do my first AG brew.

I chose to follow the recipe from the Wheeler book (BYOBRA) 3rd Edition â Flowers Original page 155, and it was a 19L brewlength (if thatâs the term for the final post boil volume).

Iâm not sure if I can post the recipe here due to copyright or not, so erring on the side of caution, then I wonât.

I wonât do a blow by blow account, as there are plenty of others on here, but here are some things that I learned for next time.

Firstly I stored my grain in the fridge and Iâd weighed out the black malt, crystal, white sugar and hops beforehand and put them in suitable sized containers. I had however got two 5lb bags of Marris Otter, which I hadnât weighed out.

I added the amount of mash water as directed at 80°C, and it dropped to a strike temperature of 72°C in a few minutes etc. I then realised I hadnât weighed out the Marris Otter ! :rofl:

I did that quickly and added the grain, first thought! :wha: The grain has been in the fridge, the temp dropped to 59°C â so I had to add more liquor (about 1.5L) to the mash tun at 80°C and it came back up to 67°C. :grin:

So all went swimmingly well from this point on, or so I thought â Iâd walked up and down the garden to the shed from the house a couple of times, and the silver reflective thing on the lawn caught my eye a couple of times :wha: . In a moment of âHitch-hikerâs â big yellow bulldozerâ :shock: I realised it was the additional mash tun insulating lid that Iâd forgotten to add â this is 60mins into the mash! (mammaryhead is an apt description)

(mammaryhead is an apt description)

Turns out that I did a reasonable job of the mash tun, as the end temperature of the mash at 90mins was 64°C.

After sparging I got an OG of 1.040 mid flow at a temp of 30° C â not sure what this means as yet.

I made a lot of notes, including the final volume of pre-boil wort which was 23.6L, so I added 2.7L of water as directed by the book.

I made notes of boil start time, the additions time (i.e. white sugar, irish moss and hops) and the end time, and it went like clockwork.

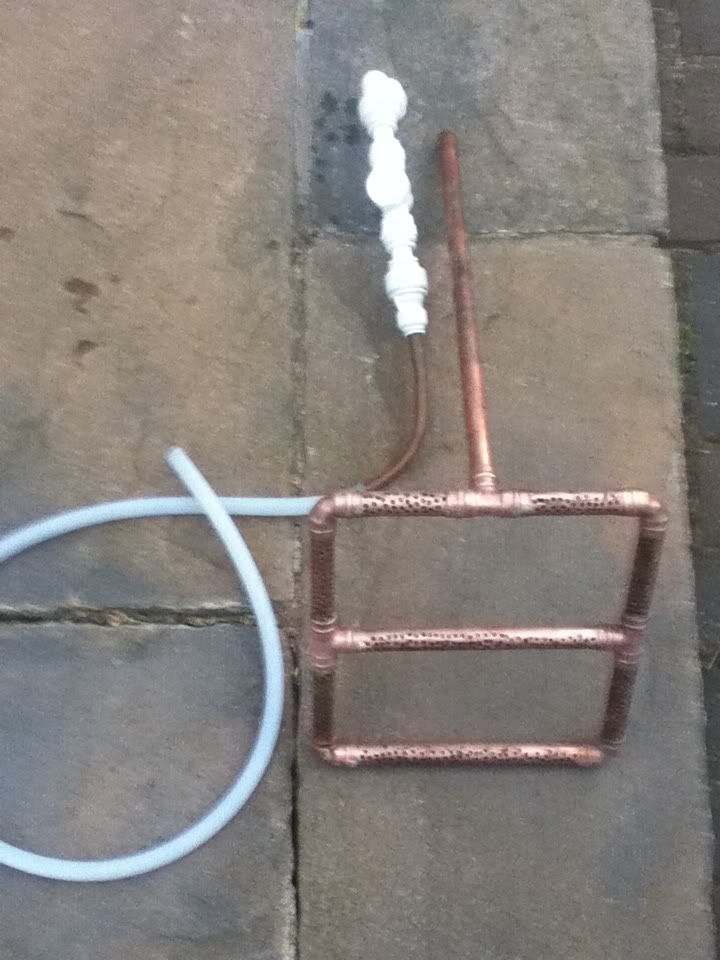

My home made chiller made short work of crash cooling.

I ended up with exactly 19L of wort, with an OG of 1.042 (predicted was 1.040) :shock: :grin:

Overall a very enjoyable experience, and one which I will be repeating soon!

Heating the water:

Sparging:

Lots of lovely brown water:

Boiling (the hop filter is on its side as the boiling action was having a volcano effect)

Steam Sterilising the FV:

Crash Cooling:

Into the FV:

And here it is fermenting away, in a yellow tub (£3 ASDA) and an aquarium heater (Argos £9.99) - Brewlabs Thames Valley II yeast:

I chose to follow the recipe from the Wheeler book (BYOBRA) 3rd Edition â Flowers Original page 155, and it was a 19L brewlength (if thatâs the term for the final post boil volume).

Iâm not sure if I can post the recipe here due to copyright or not, so erring on the side of caution, then I wonât.

I wonât do a blow by blow account, as there are plenty of others on here, but here are some things that I learned for next time.

Firstly I stored my grain in the fridge and Iâd weighed out the black malt, crystal, white sugar and hops beforehand and put them in suitable sized containers. I had however got two 5lb bags of Marris Otter, which I hadnât weighed out.

I added the amount of mash water as directed at 80°C, and it dropped to a strike temperature of 72°C in a few minutes etc. I then realised I hadnât weighed out the Marris Otter ! :rofl:

I did that quickly and added the grain, first thought! :wha: The grain has been in the fridge, the temp dropped to 59°C â so I had to add more liquor (about 1.5L) to the mash tun at 80°C and it came back up to 67°C. :grin:

So all went swimmingly well from this point on, or so I thought â Iâd walked up and down the garden to the shed from the house a couple of times, and the silver reflective thing on the lawn caught my eye a couple of times :wha: . In a moment of âHitch-hikerâs â big yellow bulldozerâ :shock: I realised it was the additional mash tun insulating lid that Iâd forgotten to add â this is 60mins into the mash!

Turns out that I did a reasonable job of the mash tun, as the end temperature of the mash at 90mins was 64°C.

After sparging I got an OG of 1.040 mid flow at a temp of 30° C â not sure what this means as yet.

I made a lot of notes, including the final volume of pre-boil wort which was 23.6L, so I added 2.7L of water as directed by the book.

I made notes of boil start time, the additions time (i.e. white sugar, irish moss and hops) and the end time, and it went like clockwork.

My home made chiller made short work of crash cooling.

I ended up with exactly 19L of wort, with an OG of 1.042 (predicted was 1.040) :shock: :grin:

Overall a very enjoyable experience, and one which I will be repeating soon!

Heating the water:

Sparging:

Lots of lovely brown water:

Boiling (the hop filter is on its side as the boiling action was having a volcano effect)

Steam Sterilising the FV:

Crash Cooling:

Into the FV:

And here it is fermenting away, in a yellow tub (£3 ASDA) and an aquarium heater (Argos £9.99) - Brewlabs Thames Valley II yeast: