Zwickel

Active Member

g´day fellow brewers,

before I´m going to introduce my automated brewing system to you, I´d like to know what funktions would be very important at the first place to you.

There are so many different brewing systems out in the world, guess there are only a few looking and working identically.

So it would be almost impossible to create an electronically controlled system that matches to all of the brewers demands.

I´d highly appreciate if you could tell us, what functions would be indispensable/compulsory for your personal brewing system.

For example I´ll start with my own demands:

doing stepped mash, therefore need a ramp temp controller

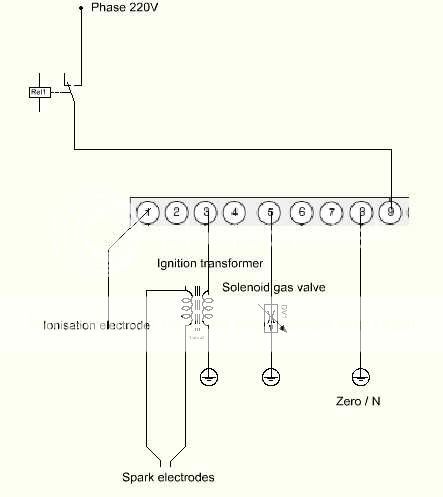

hence I´d need heating system that automatically gets switched on and off after demand;

a time controller that controls each period of time (rests, boiling time a.s.o.);

a water level controller to fill the MLT and HLT with the right amount of water, hence equipped with a solenoid valve to switch the water flow;

a level controlled wort pump, could also switched on and off manually;

an elecronically controlled stirrer, either way speed controlled and direction controlled (forth and back),

an alarm function to call the "Braumeister" if something is going wrong;

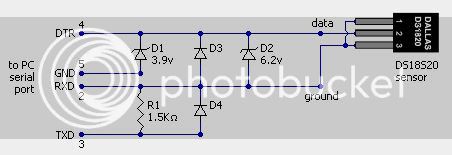

a temp monitor that shows the inlet and outlet temps of the wort chiller;

a CIP (cleaning in place) system;

so what else?

I´d highly appreciate your comments/ideas to that, so we might be able to parse my existing system into parts and reassemble to your own needs.

Cheers :

before I´m going to introduce my automated brewing system to you, I´d like to know what funktions would be very important at the first place to you.

There are so many different brewing systems out in the world, guess there are only a few looking and working identically.

So it would be almost impossible to create an electronically controlled system that matches to all of the brewers demands.

I´d highly appreciate if you could tell us, what functions would be indispensable/compulsory for your personal brewing system.

For example I´ll start with my own demands:

doing stepped mash, therefore need a ramp temp controller

hence I´d need heating system that automatically gets switched on and off after demand;

a time controller that controls each period of time (rests, boiling time a.s.o.);

a water level controller to fill the MLT and HLT with the right amount of water, hence equipped with a solenoid valve to switch the water flow;

a level controlled wort pump, could also switched on and off manually;

an elecronically controlled stirrer, either way speed controlled and direction controlled (forth and back),

an alarm function to call the "Braumeister" if something is going wrong;

a temp monitor that shows the inlet and outlet temps of the wort chiller;

a CIP (cleaning in place) system;

so what else?

I´d highly appreciate your comments/ideas to that, so we might be able to parse my existing system into parts and reassemble to your own needs.

Cheers :