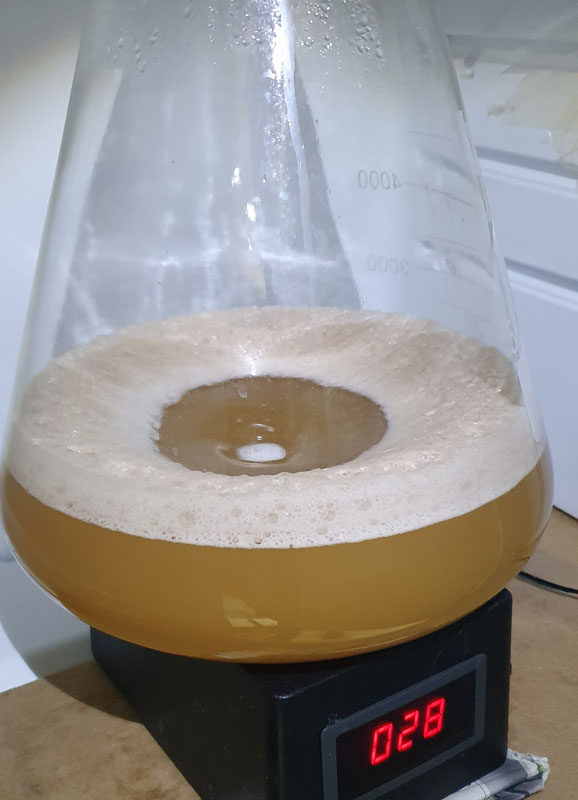

Funny you mention this - I've currently got a few litres of something fermenting in a glass demijohn (long story). It's been in there 3+ weeks and with a torch I can still see a few tiny bubbles rising and the odd bubble from the airlock. I'd swear it should be well past done by now. It makes me wonder if the plastic buckets I normally use have a bit more give/flex so don't behave in the same way. And since they're opaque(ish) I have no idea if there are normally little bubbles present or not!There was still the odd bubble coming through the blow-off tube every 90 seconds or so which I put down to some off-gassing after fermentation and was not a reason to delay the packaging.

I still cannot fathom what it is you and I do different that makes my yeast so pig-headed and stubborn. My guess is the way you build your starters means you're either breeding the yeast to attenuate more or you're simply pitching more than calculated.FG was 1.005 which may seem low but I'm starting from a relatively low OG of only 1.038 and the attenuation of 86.5% is within the range that I get from all liquid yeasts. The final ABV is 4.3% and I got one keg and 3 bottles from the fermenter. The keg was fined with dissolved leaf gelatin and is set on about 12 psi to carbonate.

First question: How long should you wait until you get stuck in? Second question: How long will you actually wait until you get stuck in?The empty fermenter smelled absolutely luscious for such a simple recipe and I'm really looking forward to trying this once it's carbonated and conditioned.