strange-steve

Quantum Brewer

- Joined

- Apr 8, 2014

- Messages

- 6,027

- Reaction score

- 5,798

I'm currently preparing this for brewday tomorrow, finally after wanting to brew this for ages. Thanks to those who helped me tweak the recipe, I'll remember you all when this is done (but only if it's good) :small

Belgian Dark Strong Ale

Recipe Specs

----------------

Batch Size (L): 18

Total Grain (kg): 8.0

Total Hops (g): 40

Expected OG: 1.097

Measured OG: 1.086

Expected FG: 1.016

Alcohol by Volume (ABV): 9.2 %

Colour (SRM): 43

Bitterness (IBU): 27

Brewhouse Efficiency (%): 68

Boil Time (Minutes): 75

Grain Bill

----------------

5.80 kg Pilsner (72.5%)

700 g Maris Otter Malt (9%)

250 g Special-B (3%)

50 g Cafe Malt (0.5%)

Added at mash-out:

150 g Carafa Special II (2%)

100 g Chocolate (1%)

Added during boil:

700 g Candi Syrup, Dark (9%)

250 g Honey (3%)

Hop Bill

----------------

15 g Magnum (15.3% AA) @ 60 Minutes (Boil)

25 g Saaz (3.6% AA) @ 30 Minutes (Boil)

Misc Bill

----------------

5 g Orange Peel @ 2 Minutes (Boil)

3 g Coriander Seed @ 2 Minutes (Boil)

1 Vanilla Pod @ 2 Minutes (Boil)

1 g Cinnamon @ 2 Minutes (Boil)

1 g Nutmeg @ 2 Minutes (Boil)

1 g Thyme @ 2 Minutes (Boil)

5 g Oak Chips for 7 Days (Secondary)

Notes

----------------

Mash in at 45° for 10 mins

62° for 30 mins

68° for 30 mins

77° for 15 mins

Fermented with Wyeast 3522 - Belgian Ardennes

Pitch at 20c and ramp up to 24 over 4 days

After 7 days ramp down to 17c and hold until FG reached

Drop to 5c and hold for 4 weeks before bottling

Water Profile

-----------------

Calcium - 90 ppm

Sulphate - 60 ppm

Chloride - 120 ppm

Alkalinity - 30 ppm

Instructions for making the candi syrup

-----------------

I already posted this in the other recipe help thread, but it makes more sense to put it here:

Equipment shot, sanitiser, non-stick pot, wooden spoon, cream of tartar to aid inversion, thermometer to avoid burning...

Turns out I didn't have as much white sugar as I thought, so I added a little demerara to make it up to 700g.

I added just enough water to dissolve the sugar plus a pinch of cream of tartar, then brought the temperature to around 130°c and held it there.

These blobs were taken 30 mins apart to show the colour change.

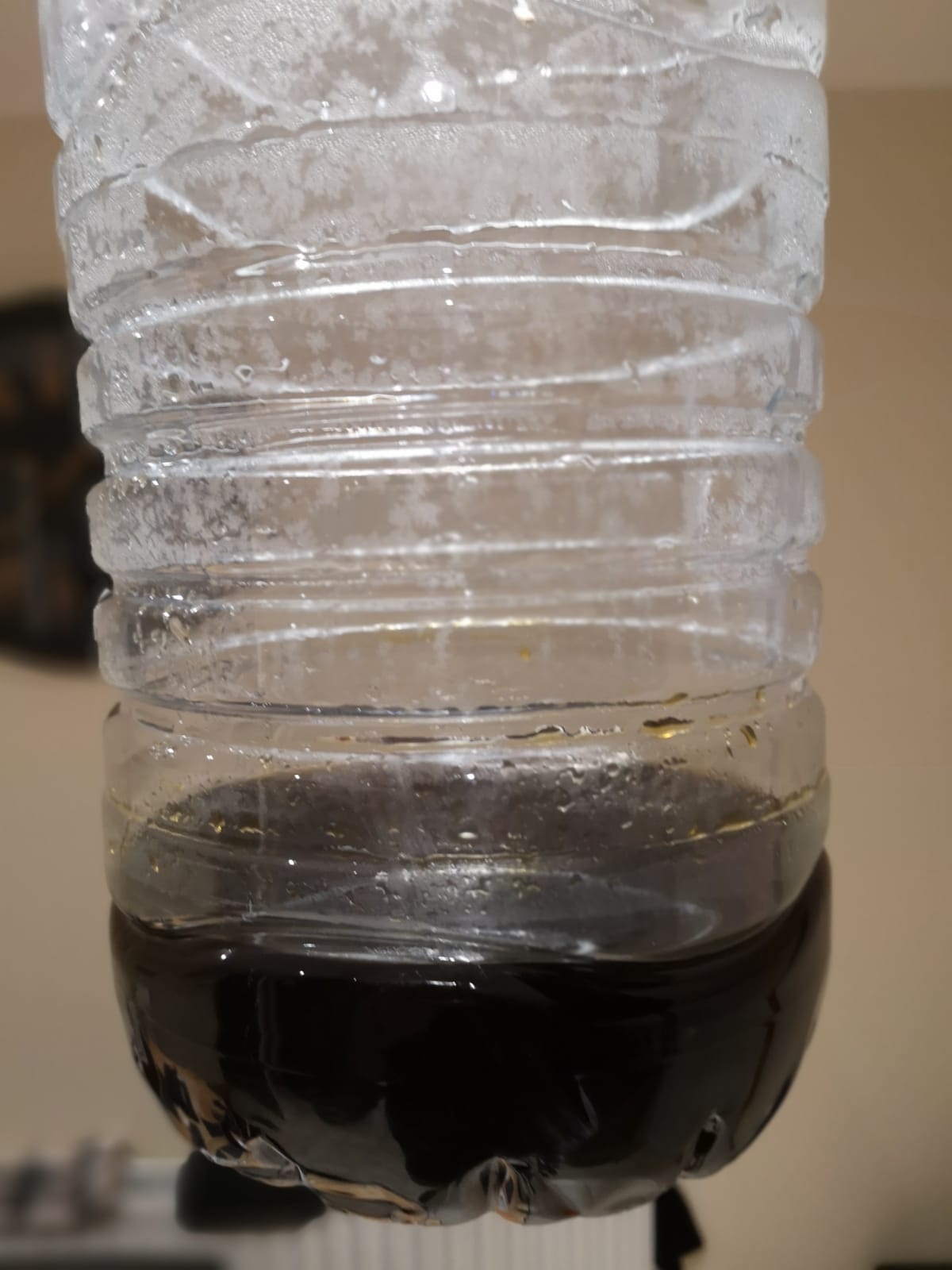

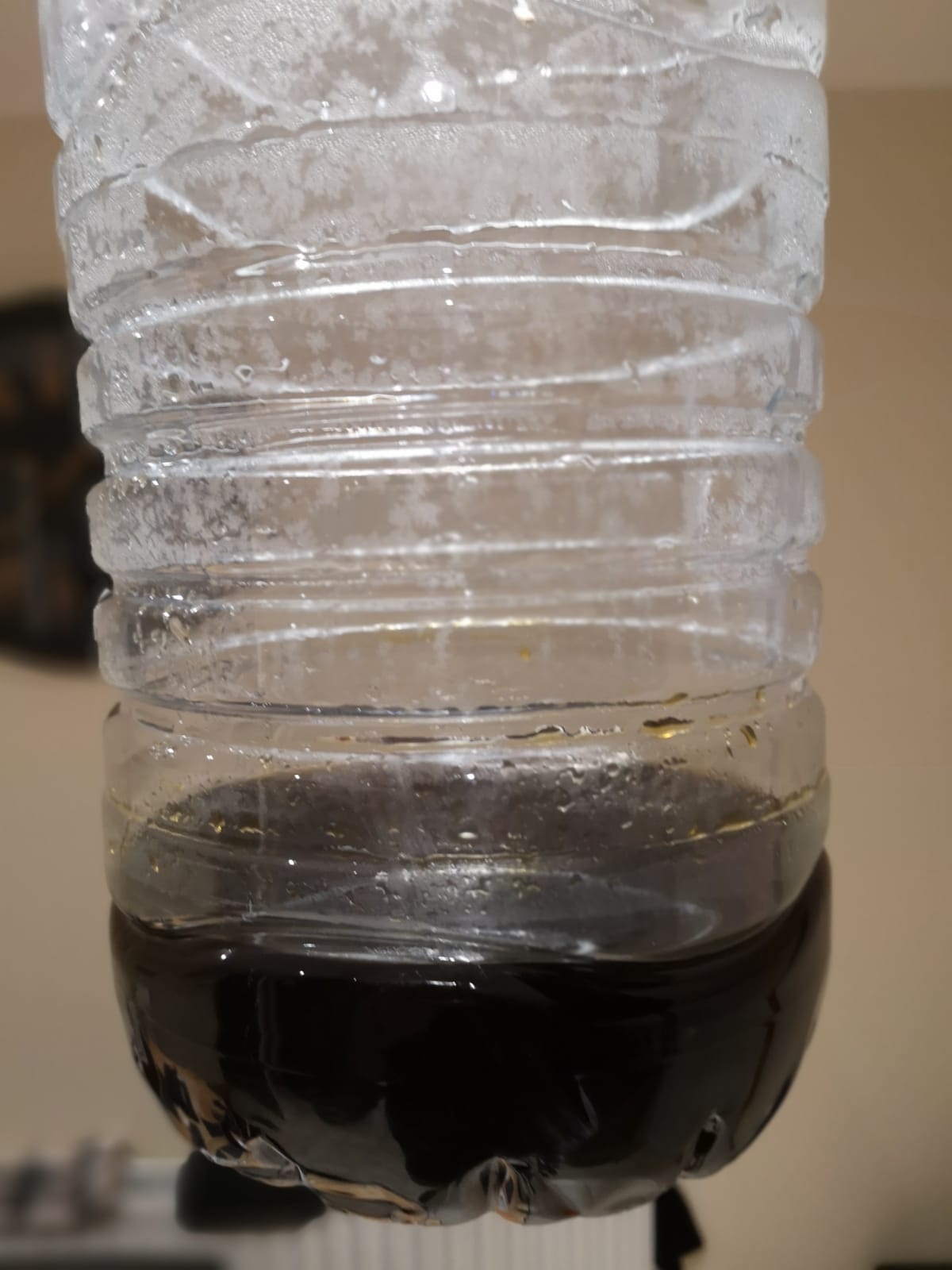

And this was the finished product after 3 hours or so.

I then added 500ml of water to stop it solidifying and poured it into a 5L bottle to keep till brew day.

It has a lovely deep red colour and it smells fantastic, so I'm pleased with how it turned out. Should add some nice flavours to the brew.

-------------------

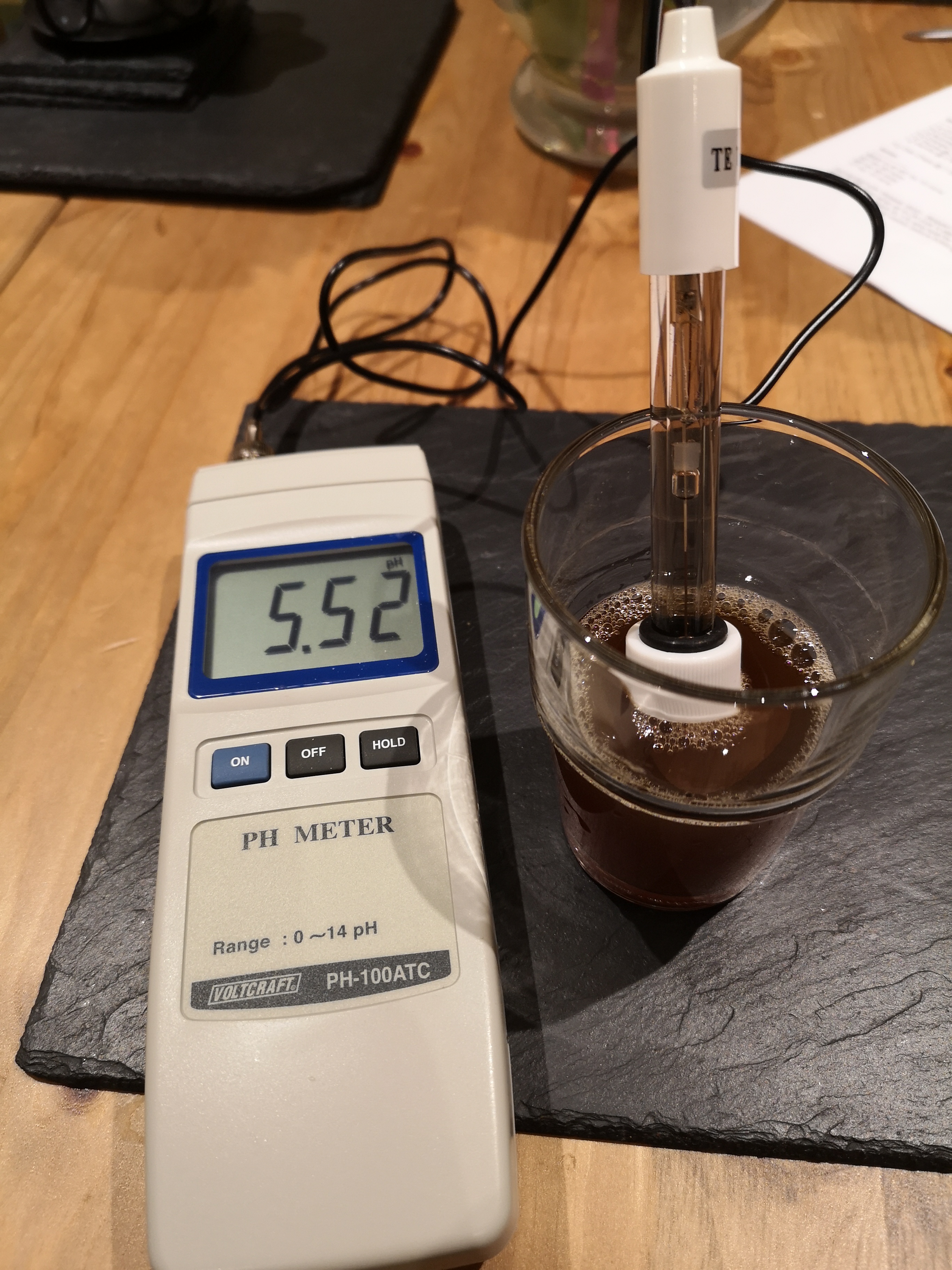

Had a slight issue with the starter; everything was going well, it was visibly fermenting within only a few hours but the following morning I found it like this. As you can see the foil cap was popped off and it could have been sitting like this for hours. Fingers crossed for no infection, but I'll have a little taste of the starter before I pitch tomorrow and if there's any doubt I'll have to go to plan B, which is to use either the Wyeast 3711 or Voss Kveik which I have in the fridge.

Belgian Dark Strong Ale

Recipe Specs

----------------

Batch Size (L): 18

Total Grain (kg): 8.0

Total Hops (g): 40

Expected OG: 1.097

Measured OG: 1.086

Expected FG: 1.016

Alcohol by Volume (ABV): 9.2 %

Colour (SRM): 43

Bitterness (IBU): 27

Brewhouse Efficiency (%): 68

Boil Time (Minutes): 75

Grain Bill

----------------

5.80 kg Pilsner (72.5%)

700 g Maris Otter Malt (9%)

250 g Special-B (3%)

50 g Cafe Malt (0.5%)

Added at mash-out:

150 g Carafa Special II (2%)

100 g Chocolate (1%)

Added during boil:

700 g Candi Syrup, Dark (9%)

250 g Honey (3%)

Hop Bill

----------------

15 g Magnum (15.3% AA) @ 60 Minutes (Boil)

25 g Saaz (3.6% AA) @ 30 Minutes (Boil)

Misc Bill

----------------

5 g Orange Peel @ 2 Minutes (Boil)

3 g Coriander Seed @ 2 Minutes (Boil)

1 Vanilla Pod @ 2 Minutes (Boil)

1 g Cinnamon @ 2 Minutes (Boil)

1 g Nutmeg @ 2 Minutes (Boil)

1 g Thyme @ 2 Minutes (Boil)

5 g Oak Chips for 7 Days (Secondary)

Notes

----------------

Mash in at 45° for 10 mins

62° for 30 mins

68° for 30 mins

77° for 15 mins

Fermented with Wyeast 3522 - Belgian Ardennes

Pitch at 20c and ramp up to 24 over 4 days

After 7 days ramp down to 17c and hold until FG reached

Drop to 5c and hold for 4 weeks before bottling

Water Profile

-----------------

Calcium - 90 ppm

Sulphate - 60 ppm

Chloride - 120 ppm

Alkalinity - 30 ppm

Instructions for making the candi syrup

-----------------

I already posted this in the other recipe help thread, but it makes more sense to put it here:

Equipment shot, sanitiser, non-stick pot, wooden spoon, cream of tartar to aid inversion, thermometer to avoid burning...

Turns out I didn't have as much white sugar as I thought, so I added a little demerara to make it up to 700g.

I added just enough water to dissolve the sugar plus a pinch of cream of tartar, then brought the temperature to around 130°c and held it there.

These blobs were taken 30 mins apart to show the colour change.

And this was the finished product after 3 hours or so.

I then added 500ml of water to stop it solidifying and poured it into a 5L bottle to keep till brew day.

It has a lovely deep red colour and it smells fantastic, so I'm pleased with how it turned out. Should add some nice flavours to the brew.

-------------------

Had a slight issue with the starter; everything was going well, it was visibly fermenting within only a few hours but the following morning I found it like this. As you can see the foil cap was popped off and it could have been sitting like this for hours. Fingers crossed for no infection, but I'll have a little taste of the starter before I pitch tomorrow and if there's any doubt I'll have to go to plan B, which is to use either the Wyeast 3711 or Voss Kveik which I have in the fridge.

Last edited:

I'll check the temperature probe on the GF tomorrow against my calibrated Comark to make sure its reading okay.

I'll check the temperature probe on the GF tomorrow against my calibrated Comark to make sure its reading okay.