I thought I might as well join the fun and post my own brewday log here in the forum. Today is an experimental bitter with the following recipe. I've never used Northdown before but Fullers use it and I very much enjoy a pint of Pride. I've also never added Chocolate malt to a bitter before but it's there in one of my favourite bitters of late: Darkstar Partridge so I'm putting the two together and doing this today:

85% Pale Malt

10% Munich Malt

3% Crystal 240 EBC

2% Low colour chocolate malt (550 EBC*)

25g Northdown 7.5%: 60 minutes: 20.7 IBU

25g Northdown 7.5%: 10 minutes: 7.5 IBU

30g EKG: 5 minutes 6.0%: 4.0 IBU

OG: 1.044

IBU: 32.2

EBC: 21.7

* Geterbrewed say this is 284 EBC which I think is way wrong. If it were 284 it would look like the crystal 240 but it's almost black like the full chocolate so I'm guessing it's 550 which is what other shops quote the low-colour chocolate to be.

I'm using Ireks Pale Malt for a change. I usually use Crisp Clear Choice but Ireks Munich is so tasty I thought I'd give their regular Pale a shot.

This will be a 25 litre split batch. 4 litres will go into a demijohn and be fermented with WLP009 (Australian). The rest will go into the main fermenter and will get Wyeast 1469 (West Yorkshire).

I originally planned to use only WLP009 but it arrived 5 months old and smelled a little sour in the vial so I decided to not risk the whole batch. Instead I overbuilt a starter, kept some in the fridge for next time if it's any good and will pitch the rest into the demijohn. The starter wort tasted OK which is encouraging.

Anyway, brewday...

Got the mash on. Aimed for 66C and got about 66.5 to 66 depending on where I probed. That's fine. Mashed for an hour.

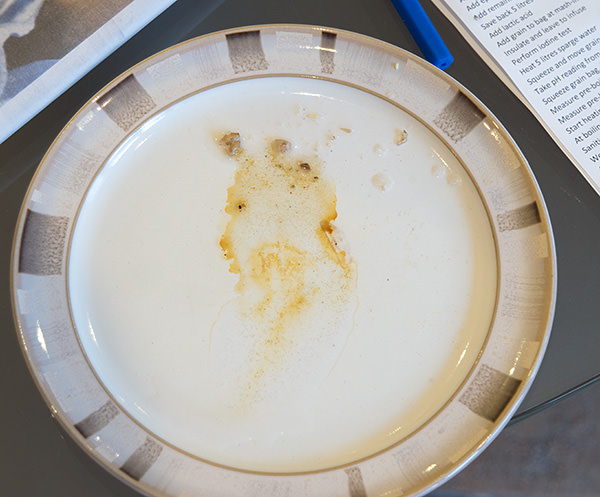

Did the iodine test at 60 minutes to confirm it was done. No problems there.

Dunk sparged for about 10 minutes. Push, prod and agitate the bag. Lifted and squeezed the heck out of it. Only lost about 600ml to the 4.4kg grain bill. Beersmith is showing a healthy 83% mash efficiency.

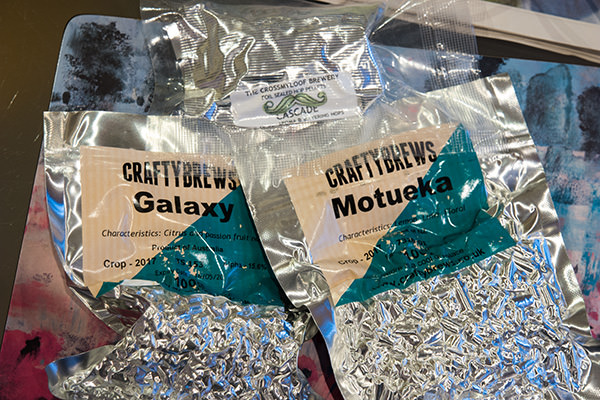

Got the first lot of hops measured and ready. Lovely fresh pungent smell from the bag. Crossmyloof hops are always fresh.

I use a large 5 gal hop bag so they get lots of freedom to infuse during the boil.

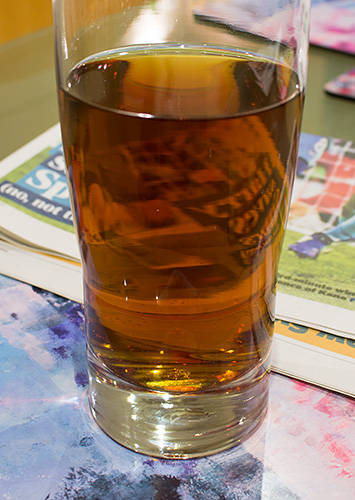

I collected 26 litres of wort in the end. I stopped my immersion chiller at 26C and put the fermenter into the fridge to get it down to about 20C where I'll pitch the yeast.

OG was 1.044 according to two different hydrometers, bang on Beersmith's prediction. I wish I knew why my refractometer is so unreliable. Today it was consistently +4pts above both the hydrometers on pre and post boil readings. On other days it will match 1 for 1. I wonder if wort clarity has anything to do with the degree of refraction. I don't know.

All in all a uneventful brewday that was complete including washing up in 6 hours. Now comes the waiting :)

85% Pale Malt

10% Munich Malt

3% Crystal 240 EBC

2% Low colour chocolate malt (550 EBC*)

25g Northdown 7.5%: 60 minutes: 20.7 IBU

25g Northdown 7.5%: 10 minutes: 7.5 IBU

30g EKG: 5 minutes 6.0%: 4.0 IBU

OG: 1.044

IBU: 32.2

EBC: 21.7

* Geterbrewed say this is 284 EBC which I think is way wrong. If it were 284 it would look like the crystal 240 but it's almost black like the full chocolate so I'm guessing it's 550 which is what other shops quote the low-colour chocolate to be.

I'm using Ireks Pale Malt for a change. I usually use Crisp Clear Choice but Ireks Munich is so tasty I thought I'd give their regular Pale a shot.

This will be a 25 litre split batch. 4 litres will go into a demijohn and be fermented with WLP009 (Australian). The rest will go into the main fermenter and will get Wyeast 1469 (West Yorkshire).

I originally planned to use only WLP009 but it arrived 5 months old and smelled a little sour in the vial so I decided to not risk the whole batch. Instead I overbuilt a starter, kept some in the fridge for next time if it's any good and will pitch the rest into the demijohn. The starter wort tasted OK which is encouraging.

Anyway, brewday...

Got the mash on. Aimed for 66C and got about 66.5 to 66 depending on where I probed. That's fine. Mashed for an hour.

Did the iodine test at 60 minutes to confirm it was done. No problems there.

Dunk sparged for about 10 minutes. Push, prod and agitate the bag. Lifted and squeezed the heck out of it. Only lost about 600ml to the 4.4kg grain bill. Beersmith is showing a healthy 83% mash efficiency.

Got the first lot of hops measured and ready. Lovely fresh pungent smell from the bag. Crossmyloof hops are always fresh.

I use a large 5 gal hop bag so they get lots of freedom to infuse during the boil.

I collected 26 litres of wort in the end. I stopped my immersion chiller at 26C and put the fermenter into the fridge to get it down to about 20C where I'll pitch the yeast.

OG was 1.044 according to two different hydrometers, bang on Beersmith's prediction. I wish I knew why my refractometer is so unreliable. Today it was consistently +4pts above both the hydrometers on pre and post boil readings. On other days it will match 1 for 1. I wonder if wort clarity has anything to do with the degree of refraction. I don't know.

All in all a uneventful brewday that was complete including washing up in 6 hours. Now comes the waiting :)