Thanks for the interest.

manxape said:

Very nice! Just out of interest what are those shiny quick disconnects you're using and where did you get them from? I'm looking for something similar on my brewery refurb.

Camlock fittings from Intrico Products, but watch out for the postage costs, order all you need plus spares. ( Do you happen to know Graham and Debbie Bradley who live in Onchan ?)

mashman said:

Cracking build. Where did you source the switches and lamps for the control panel. :thumb:

Lamps and switches came from Auberins in USA, but I also got some lamps from China, which are identical. I do have some spare lamps which I do not require.

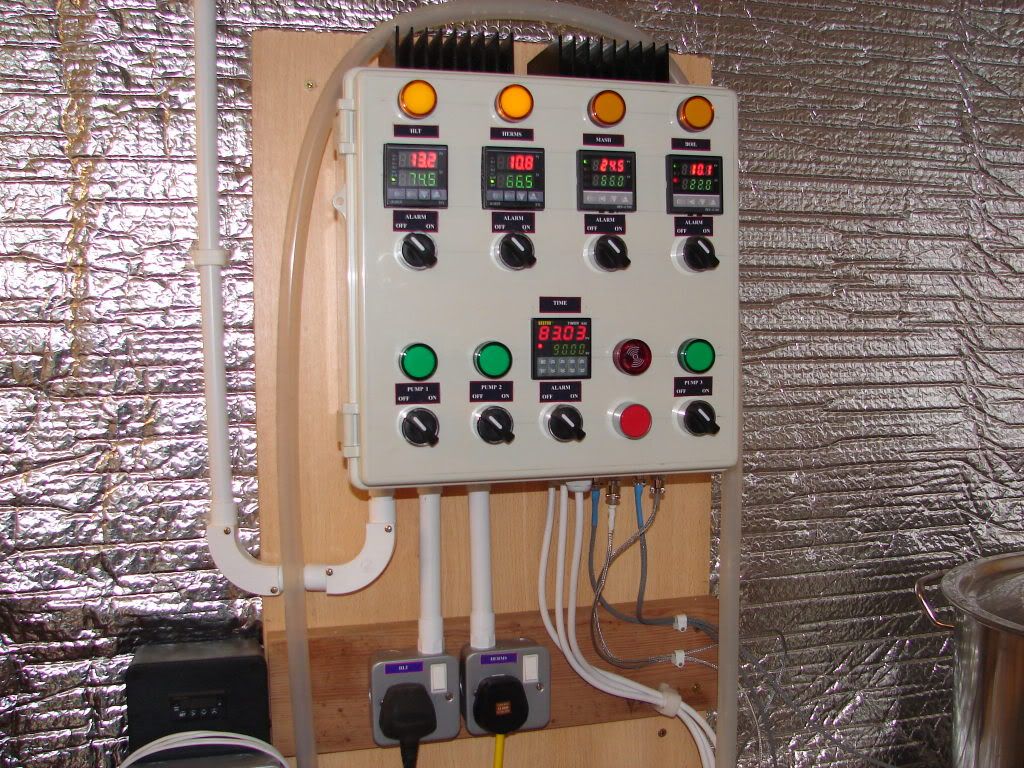

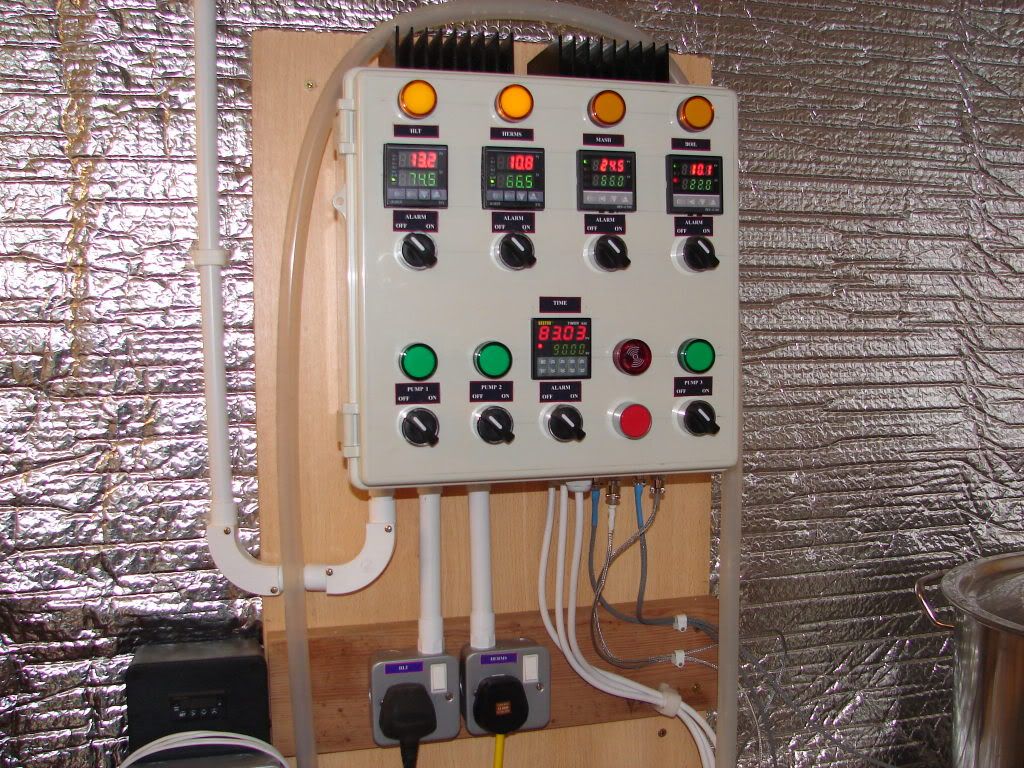

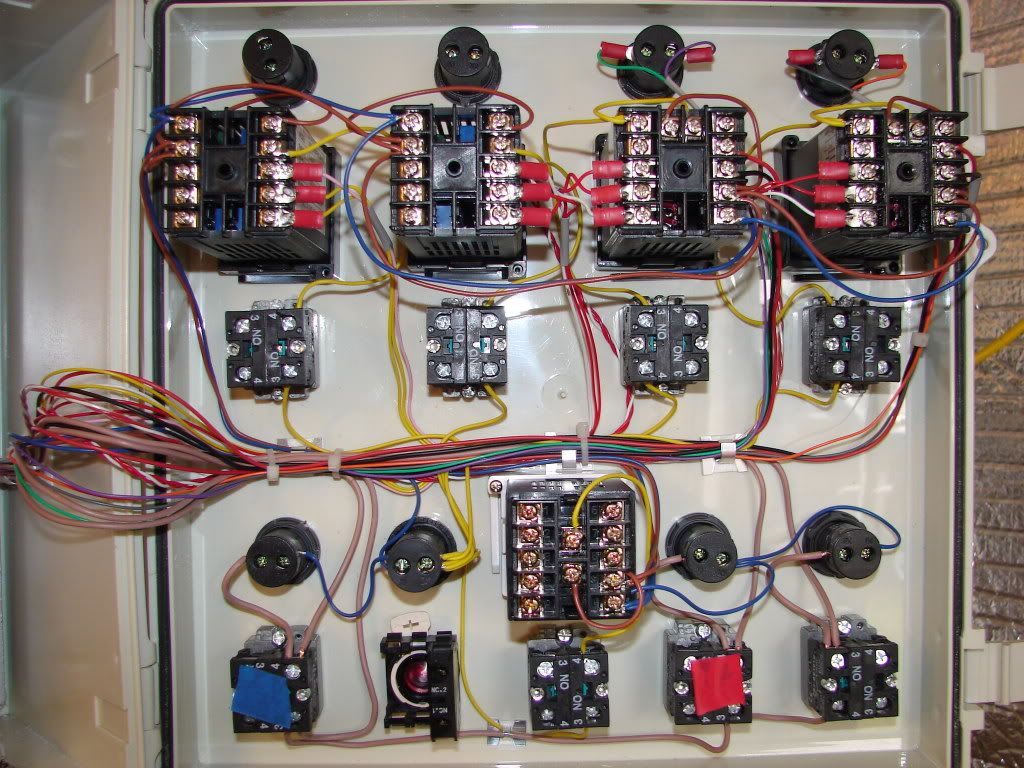

The control panel idea is stolen from the Electric Brewery with modifications to suit my requirements. It has four pid's. The two on the left are Auber SYL-2342 and control the HLT and Herms via SSR's. The two on the right are cheapo Chinese REX-C100's and are to show Mash temp and Boiler temp, but do not control anything. The timer in centre is a Sestos B2E £18 free p&p ebay.

All Pt100 sensors are from Auber's as are the SSR's and heatsinks. I do like the Pt100 sensors as they can be unplugged from the sensor wires. ( makes cleaning easier ) My only complaint with them is that the plugs are a bit fragile where the wires connect inside. I had to repair one which was badly soldered. I brought extra plugs and sockets from Aubers for the control box connections, but if doing again I would use XLR plugs and sockets, they are much more robust.

I have three pumps. One ( Totton ) for mash liquor, and sparge, one ( Totton ) for herms, and one ( solar pump ) for boiler whirlpool to speed up cooling using immersion cooler and to pump to fermenter. When I first built the system the boiler was higher than it is now, and I had to pump from MT to boiler, now I have lowered the boiler so can gravity feed from MT.

The decals on the control panel are made from self adhesive photo card, and printed from computer using standard word processor.

Next instalment I will describe the Herms build, with some more pics.

Cheers for now. John