BREWING IN TWO SHEETS!

I have been partial mashing for a year and intended to start AG this year. Well I have I decided on BIAB to keep the costs down and thought I'd just get a big stockpot to boil it all in. Whist fathoming everything else I needed I realised that you don't actually need a bag!

I decided on BIAB to keep the costs down and thought I'd just get a big stockpot to boil it all in. Whist fathoming everything else I needed I realised that you don't actually need a bag!

All you need is a nylon voile curtain. The bulk of the material is around the outside, so if you put your grains in the middle you can just use a cord with a slip knot in it to fulfill the same function as a draw string. The harder the weight tries to pull the material through the knot, the tighter the knot gets. You can filter the boiled hops in a second sheet in the same way.

Setup costs if you've never even done a kit before are less than £100!

That's for everything needed. Here is a list of all the equipment you will require.

A large stockpot-mine's 32l

An FV

2 sheets of nylon voile of about 1 sq. meter each.

A piece of nylon cord about 2m in length.

A plastic spoon.

A thermometer.

A hydrometer.

A luggage strap or piece of elastic.

Something to insulate your stockpot.

A teaspoon.

That's it except for a stove of some kind. If you don't have one already then your priority should perhaps not be to brew beer.

The method is simple.

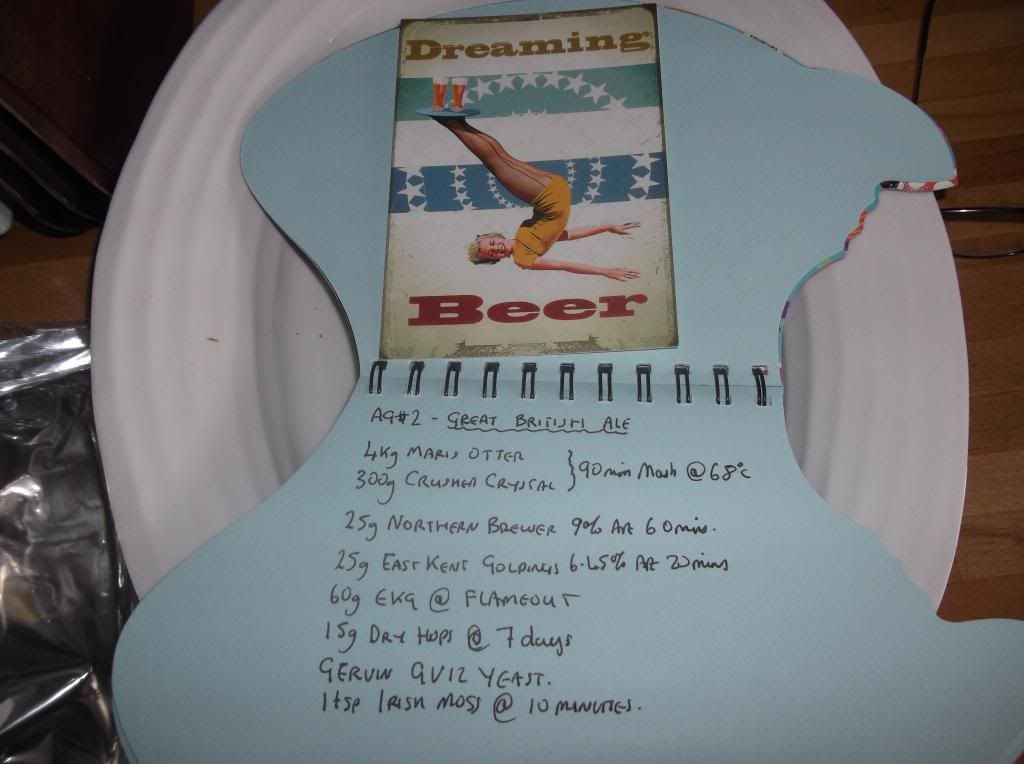

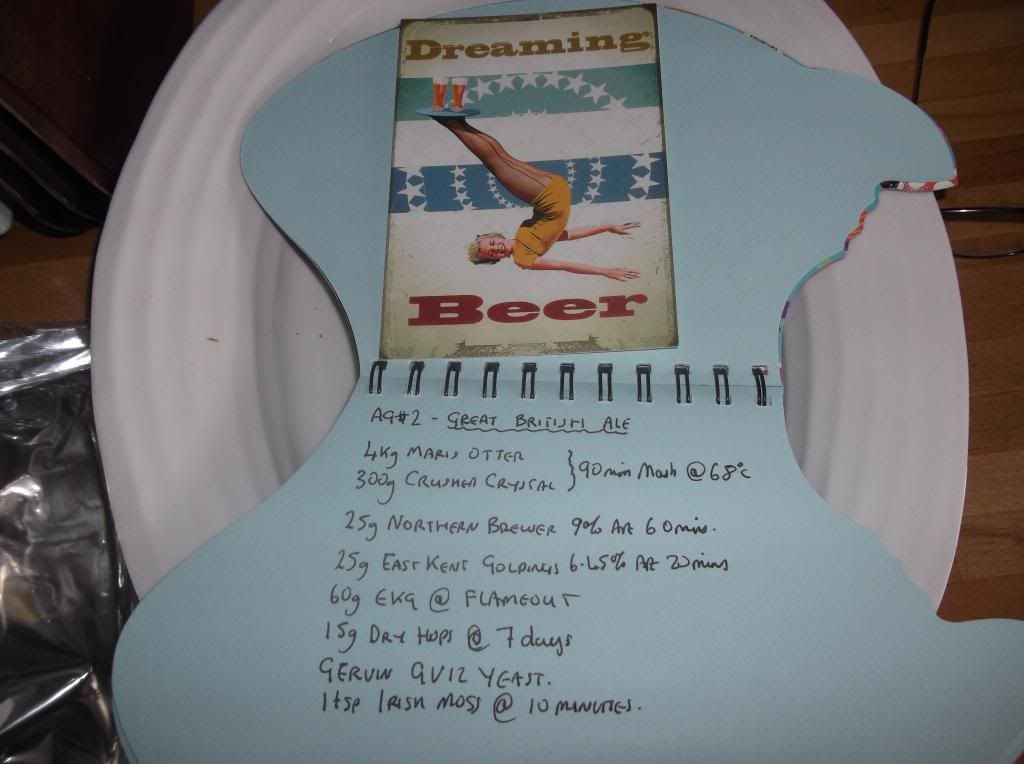

Here's today's recipe.

Heat your entire brew length plus 5 litres to 70C. Use your first sheet to line your stockpot and strap it around the outside so it can't fall in or get burned by the stove.

Add your grain, put the lid on and insulate, then leave it for at least 90 mins. Put it back on the stove with the thermometer still in and stir continuously as you heat to 78C. Then take it off the stove. Be diligent here, the temp. can rise quicker than you think.

Remove your strap and gather the top of the sheet from round the stockpot. Tie a slip knot over it and hoist. After it's cooled a bit you can jiggle gently to get as much liquid out as you like. Just be carefull not to sueeze too much since this may release tannins.

Get the pan back on the stove and heat to a boil. Check the rising temperature but be warned, with a domestic stove it will take a looooooooong time. EDIT-Keeping the lid on during heating will save much time. I also boil with the lid on. Some may object but I didn't realise any objections existed 'til I read another thread! The beer tastes fine so I will continue the practice :thumb:

Add your first hops. I give them 40 mins before adding the second lot. 10 mins later I add a teaspoon of irish moss. 10 minutes after that I romove the pot from the heat, add my flameout hops and leave to steep for 20 minutes.

Strap your second sheet over your sterile FV, as you did with the stockpot earlier. Man up and pour the entire pan of wort and hops into the FV, then hoist the sheet as previously. Wiggle and jiggle but don't squeeze. This way you will catch a suprising amount of break material.

You can chill if you like but if you have no chiller you can leave overnight or until the temp is right to pitch your yeast. I like to rehydrate my dried yeast in wter, not wort, until it gets a head before pitching.

So here's a dirty sheet! It shows the capture of some break material. Rememberr jiggle, don't squeeze. It makes a big difference to the clarity of the wort.

I put 28l into my 32l pot and with 4kg of M Otter and 300g of crystal it was well full.

I got a shade under 22l in my FV so I made it up to 23l and checked th OG.

1046. Ignoring the crushed crystal because it will make very little difference to the OG, I work that out as 89.66% efficiency. Why so good? Because there's so little waste. A little water is left in the malt and a little in the hops but it's not much.

With no chilling you are relying on the fermentation and the irish moss to clear things up. Seems to work so if it aint broke...........

I'll leave it to ferment and clear for 14 days then go straight to my barrel, though you could bottle if you wished.

Loads of recipes can be done this way. mines a simple one above with a massive whack of EKG at flameout to make it extra special. I'll post my impressions in a month.

I have been partial mashing for a year and intended to start AG this year. Well I have

All you need is a nylon voile curtain. The bulk of the material is around the outside, so if you put your grains in the middle you can just use a cord with a slip knot in it to fulfill the same function as a draw string. The harder the weight tries to pull the material through the knot, the tighter the knot gets. You can filter the boiled hops in a second sheet in the same way.

Setup costs if you've never even done a kit before are less than £100!

That's for everything needed. Here is a list of all the equipment you will require.

A large stockpot-mine's 32l

An FV

2 sheets of nylon voile of about 1 sq. meter each.

A piece of nylon cord about 2m in length.

A plastic spoon.

A thermometer.

A hydrometer.

A luggage strap or piece of elastic.

Something to insulate your stockpot.

A teaspoon.

That's it except for a stove of some kind. If you don't have one already then your priority should perhaps not be to brew beer.

The method is simple.

Here's today's recipe.

Heat your entire brew length plus 5 litres to 70C. Use your first sheet to line your stockpot and strap it around the outside so it can't fall in or get burned by the stove.

Add your grain, put the lid on and insulate, then leave it for at least 90 mins. Put it back on the stove with the thermometer still in and stir continuously as you heat to 78C. Then take it off the stove. Be diligent here, the temp. can rise quicker than you think.

Remove your strap and gather the top of the sheet from round the stockpot. Tie a slip knot over it and hoist. After it's cooled a bit you can jiggle gently to get as much liquid out as you like. Just be carefull not to sueeze too much since this may release tannins.

Get the pan back on the stove and heat to a boil. Check the rising temperature but be warned, with a domestic stove it will take a looooooooong time. EDIT-Keeping the lid on during heating will save much time. I also boil with the lid on. Some may object but I didn't realise any objections existed 'til I read another thread! The beer tastes fine so I will continue the practice :thumb:

Add your first hops. I give them 40 mins before adding the second lot. 10 mins later I add a teaspoon of irish moss. 10 minutes after that I romove the pot from the heat, add my flameout hops and leave to steep for 20 minutes.

Strap your second sheet over your sterile FV, as you did with the stockpot earlier. Man up and pour the entire pan of wort and hops into the FV, then hoist the sheet as previously. Wiggle and jiggle but don't squeeze. This way you will catch a suprising amount of break material.

You can chill if you like but if you have no chiller you can leave overnight or until the temp is right to pitch your yeast. I like to rehydrate my dried yeast in wter, not wort, until it gets a head before pitching.

So here's a dirty sheet! It shows the capture of some break material. Rememberr jiggle, don't squeeze. It makes a big difference to the clarity of the wort.

I put 28l into my 32l pot and with 4kg of M Otter and 300g of crystal it was well full.

I got a shade under 22l in my FV so I made it up to 23l and checked th OG.

1046. Ignoring the crushed crystal because it will make very little difference to the OG, I work that out as 89.66% efficiency. Why so good? Because there's so little waste. A little water is left in the malt and a little in the hops but it's not much.

With no chilling you are relying on the fermentation and the irish moss to clear things up. Seems to work so if it aint broke...........

I'll leave it to ferment and clear for 14 days then go straight to my barrel, though you could bottle if you wished.

Loads of recipes can be done this way. mines a simple one above with a massive whack of EKG at flameout to make it extra special. I'll post my impressions in a month.