darlacat

Well-Known Member

- Joined

- Jun 5, 2018

- Messages

- 121

- Reaction score

- 59

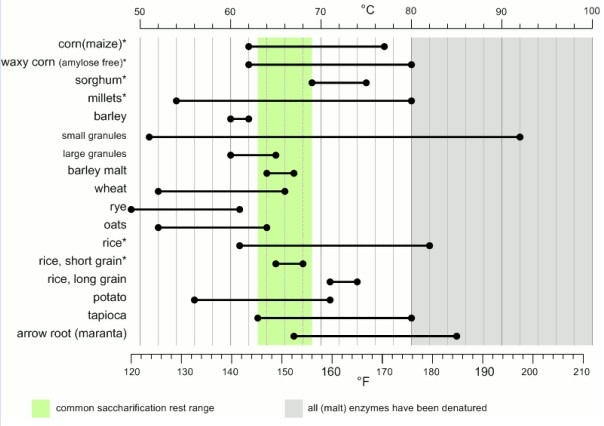

Brewing a saison today, and had an absolute disaster using a ferulic acid rest. Have done this step before with no problems in wheat beers. However, today it caused the wort to gelatinise, forming milky clumps, and burned onto the element, causing the mash tun to trip out. I emptied and cleaned out the mash tun, filtered out the gelatinised clumps, and put everything back in - but as soon as the element touched the wort, it scorched again!

I was following the mash schedule from the Farmhouse Ales book:

- 30 min rest at 45c

- 15 min rest at 55c (didn't make it this far)

- 30min rest at 62c

- 15min rest at 68c

Grain was extra pale with small amounts of bohemian pilsner, torrified wheat and carapils (<5% each for the last two).

What went on here?

Is the grain from this batch salvageable, or shall I just dump it and start again...?

I was following the mash schedule from the Farmhouse Ales book:

- 30 min rest at 45c

- 15 min rest at 55c (didn't make it this far)

- 30min rest at 62c

- 15min rest at 68c

Grain was extra pale with small amounts of bohemian pilsner, torrified wheat and carapils (<5% each for the last two).

What went on here?

Is the grain from this batch salvageable, or shall I just dump it and start again...?