And sadly all gone now. Ah well, an empty keg is a blank slate waiting to be filled.That really is one tasty looking beverage you've got there

Cheers. Tom

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help Support The Homebrew Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

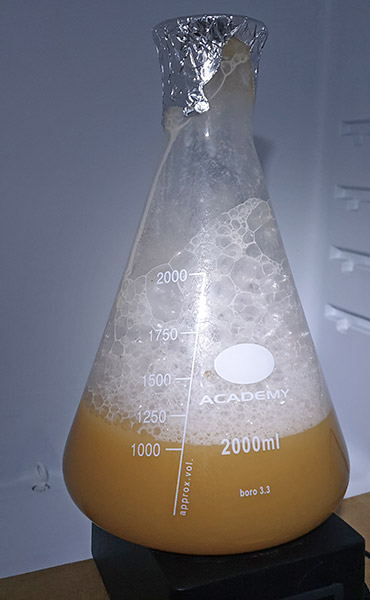

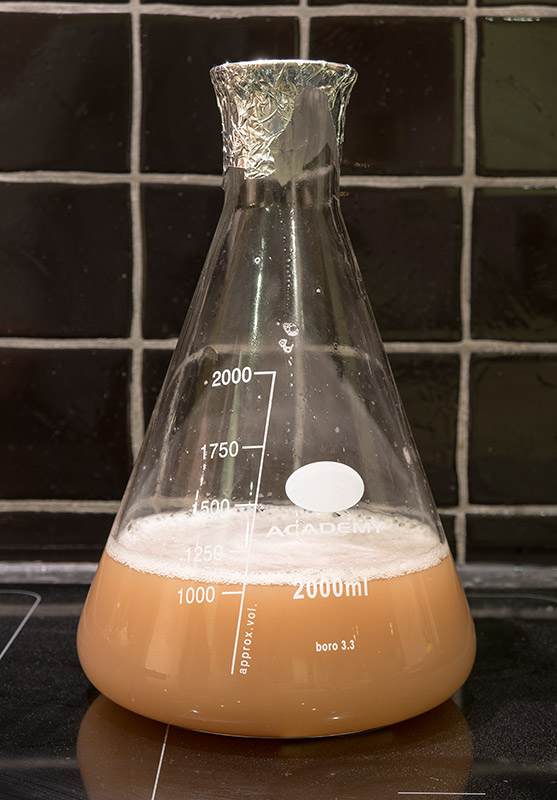

It's yeast starter day today in preparation for a brew this weekend and it's the fourth and final re-use of the Omega OYL-052 DIPA yeast that I've become rather attached to since I started using it back in August. I'll be buying more of it next year but after this one it's going to be a few pilsners in a row so I'll be needing appropriate lager yeasts for those.

Anyway, with no overbuild to consider I only needed a litre starter so I opted for the 2 litre flask. It's spinning away on the stir plate in the brew-fridge as I type.

The beer itself will be an ordinary pale ale hopped with English hops and timed to be ready for the run up to Christmas. Recipe to follow when I've finished the customary last minute faffing with the details.

Anyway, with no overbuild to consider I only needed a litre starter so I opted for the 2 litre flask. It's spinning away on the stir plate in the brew-fridge as I type.

The beer itself will be an ordinary pale ale hopped with English hops and timed to be ready for the run up to Christmas. Recipe to follow when I've finished the customary last minute faffing with the details.

Today is brew day for my English IPA that should be ready in time for the Christmas period. I'm calling it Flagstaff IPA and here's the recipe I came up with:

While weighing out the grain I realised I was 2kg short on the base pale malt and I could either open a new, sealed plastic bag of Maris Otter or make up the difference with some from already opened bags of pilsner and extra pale malt. I opted to use the bags that were already open.

I had a taste of a few grains of the extra pale. It's been open for a year and it didn't taste very fresh. Not an off taste, just not very fresh. By contrast the pilsner tasted crisp, crunchy and cracker-like. I used that and the kilo or so of old extra-pale is now bird food.

I crushed the grain while waiting for the treated Ashbeck water to come to mash temperature. I mashed in at about 66C and left the thermopot with the lid on for an hour.

The iodine test showed that conversion was complete and I took pre-boil measurements after doing a 10 minute sparge with 5 litres of water in a spare bucket. Pre-boil gravity was on target at 1.042 and I was about 400ml short on the predicted volume which is fine by me.

The wort was brought to the boil while stirring and then the boil power was reduced to about 1.6kW for the duration. Just enough to maintain the gentlest of rolling boils.

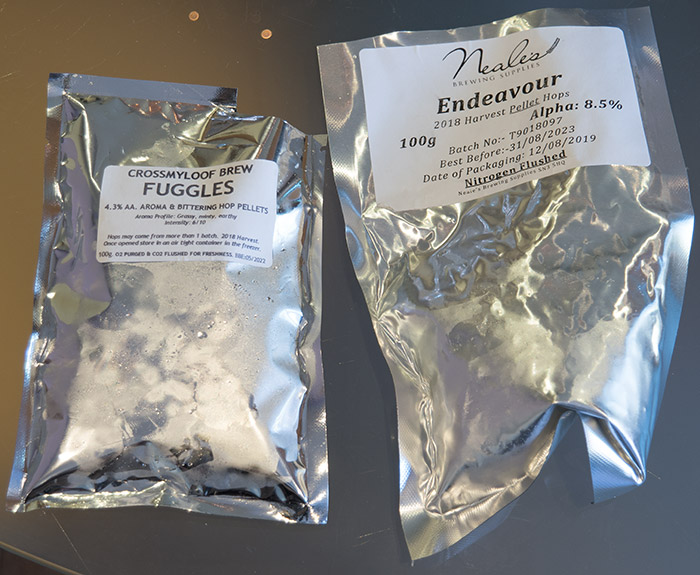

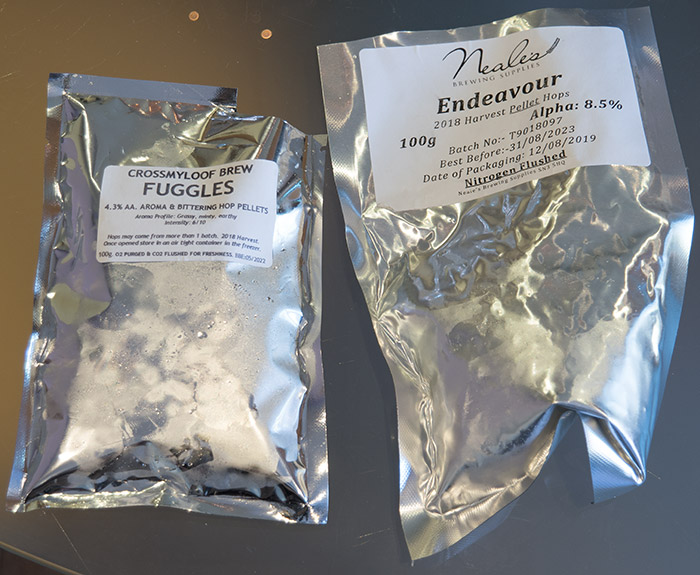

The hops for today's recipe are all English. Endeavour is an intriguing hop. Fruity, with a bit of a gooseberry bitterness, I think it will go well partnered with the earthy Fuggle flavour.

Boil finished, chilled it down to 24C with the immersion chiller and transferred the whole lot to the sterilised fermenter. The 400ml shortfall after the mash carried over to the final volume and I got 23.6 litres into the fermenter versus the target of 24 litres.

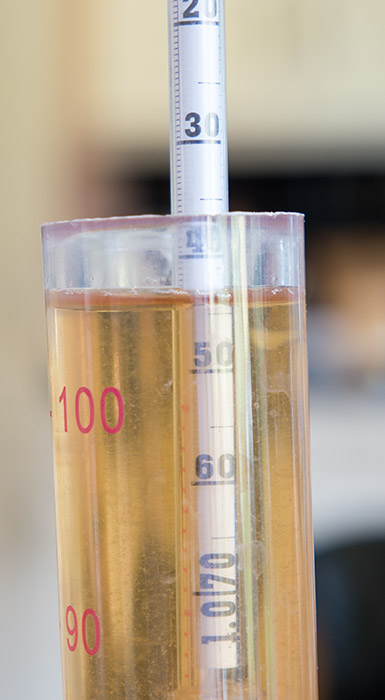

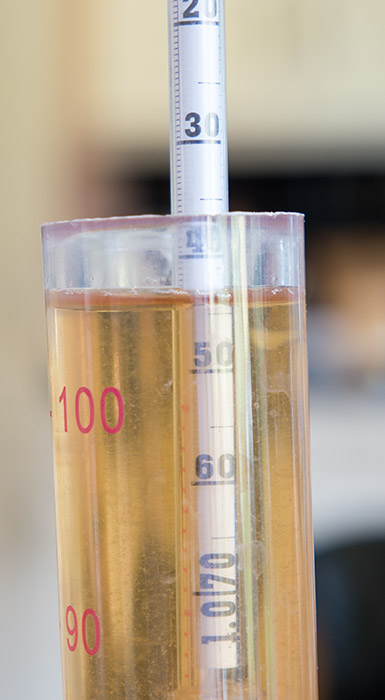

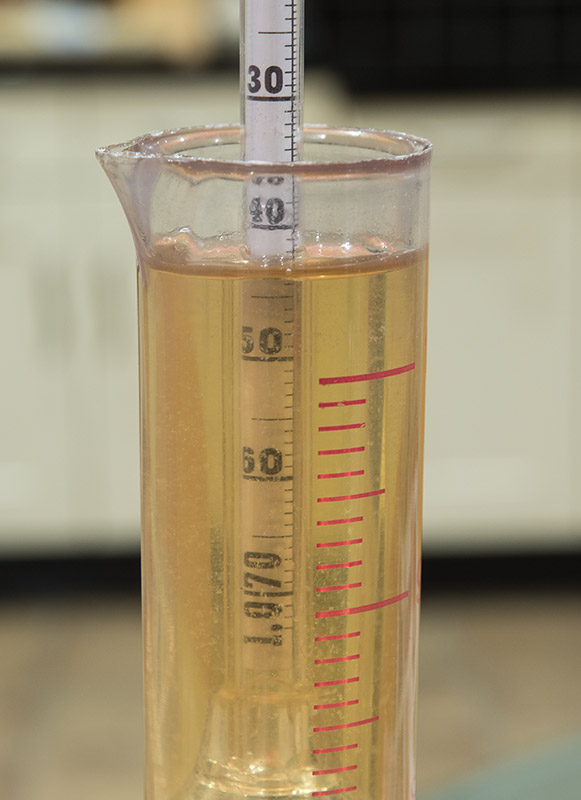

The wort's a lovely pale colour with an OG of either 1.044 or 1.045 depending on whether you believe the hydrometer or the refractometer. It's now in the brew-fridge while it comes down to around 20C when I'll pitch the decanted flask of OYL-052 yeast. Yeast seem to rock through the worts that I create so I've no reason to suspect I won't achieve the usual 82 to 86% attenuation, giving a final ABV of around 4.9% give or take.

Started at 6:30am. All washed up and done by 12:30 for lunch.

Code:

Recipe Specifications

--------------------------

Recipe: Flagstaff IPA

Batch Size (fermenter): 24.00 L

Estimated OG: 1.045 SG

Estimated Color: 11.6 EBC

Estimated IBU: 32.4 IBUs

Brewhouse Efficiency: 75.00 %

Est Mash Efficiency: 75.6 %

Boil Time: 60 Minutes

Finished water profile: Ca:53, Mg:9, Na:10, SO4:73, Cl:59

Ingredients:

------------

Amt Name Type %/IBU

29.62 L Tesco Ashbeck Water -

2.20 ml Lactic Acid (Mash) Water Agent -

1.70 g Calcium Chloride (Mash) Water Agent -

1.70 g Gypsum (Calcium Sulfate) (Mash) Water Agent -

1.50 g Epsom Salt (MgSO4) (Mash) Water Agent -

3.75 kg IREKS Pale Ale Malt (6.0 EBC) Grain 82.0 %

0.46 kg IREKS Munich Malt (20.0 EBC) Grain 10.0 %

0.23 kg Barley, Flaked (Thomas Fawcett) (3.9 EBC) Grain 5.0 %

0.14 kg Melanoidin (Weyermann) (70.0 EBC) Grain 3.0 %

0.40 g Calcium Chloride (Sparge) Water Agent -

0.40 g Gypsum (Calcium Sulfate) (Sparge) Water Agent -

0.30 g Epsom Salt (MgSO4) (Sparge) Water Agent -

0.20 ml Lactic Acid (Sparge) Water Agent -

10.00 g Endeavour [8.50 %] - Boil 60.0 min Hop 9.8 IBUs

11.00 g Endeavour [8.50 %] - Boil 15.0 min Hop 5.3 IBUs

11.00 g Fuggle [4.30 %] - Boil 15.0 min Hop 2.5 IBUs

16.00 g Endeavour [8.50 %] - Boil 10.0 min Hop 5.7 IBUs

16.00 g Fuggle [4.30 %] - Boil 10.0 min Hop 2.6 IBUs

1.00 Items Whirlfloc Tablet (Boil 7.0 mins) Fining -

23.00 g Endeavour [8.50 %] - Boil 5.0 min Hop 4.5 IBUs

23.00 g Fuggle [4.30 %] - Boil 5.0 min Hop 2.1 IBUs

1.0 pkg DIPA Ale (Omega #OYL-052) Yeast -

Mash Schedule: Single Infusion, Medium Body, Batch Sparge

Total Grain Weight: 4.57 kg

----------------------------

Name Description Step Temperat Step Time

Mash In Add 24.62 L of water at 69.3 C 66.0 C 60 min

Sparge: Dunk sparge with 5 L of water at 75.0 CWhile weighing out the grain I realised I was 2kg short on the base pale malt and I could either open a new, sealed plastic bag of Maris Otter or make up the difference with some from already opened bags of pilsner and extra pale malt. I opted to use the bags that were already open.

I had a taste of a few grains of the extra pale. It's been open for a year and it didn't taste very fresh. Not an off taste, just not very fresh. By contrast the pilsner tasted crisp, crunchy and cracker-like. I used that and the kilo or so of old extra-pale is now bird food.

I crushed the grain while waiting for the treated Ashbeck water to come to mash temperature. I mashed in at about 66C and left the thermopot with the lid on for an hour.

The iodine test showed that conversion was complete and I took pre-boil measurements after doing a 10 minute sparge with 5 litres of water in a spare bucket. Pre-boil gravity was on target at 1.042 and I was about 400ml short on the predicted volume which is fine by me.

The wort was brought to the boil while stirring and then the boil power was reduced to about 1.6kW for the duration. Just enough to maintain the gentlest of rolling boils.

The hops for today's recipe are all English. Endeavour is an intriguing hop. Fruity, with a bit of a gooseberry bitterness, I think it will go well partnered with the earthy Fuggle flavour.

Boil finished, chilled it down to 24C with the immersion chiller and transferred the whole lot to the sterilised fermenter. The 400ml shortfall after the mash carried over to the final volume and I got 23.6 litres into the fermenter versus the target of 24 litres.

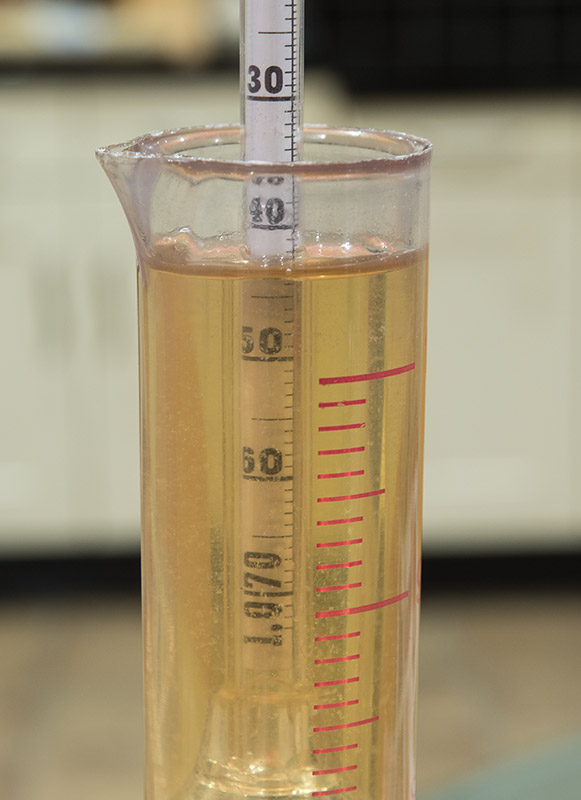

The wort's a lovely pale colour with an OG of either 1.044 or 1.045 depending on whether you believe the hydrometer or the refractometer. It's now in the brew-fridge while it comes down to around 20C when I'll pitch the decanted flask of OYL-052 yeast. Yeast seem to rock through the worts that I create so I've no reason to suspect I won't achieve the usual 82 to 86% attenuation, giving a final ABV of around 4.9% give or take.

Started at 6:30am. All washed up and done by 12:30 for lunch.

...and the half decanted starter (I wanted 500ml to make up the volume undershoot) was pitched at 16:30. 5 hours later and I'm getting slow bubbles through the blowoff tube. Great yeast this Conan strain. Very aggressive, very reliabe.

A less than ideal and somewhat hasty smartphone photo taken tonight as I wash down dinner with a few pints of my Outback Ale No.2.. Clarity is on-point, thanks I believe to the performance of the yeast and the Kwik-Clear finings added to the keg. The lacing of the head down the glass seems to indicate that the overall process is good but never mind that technical stuff what does it taste like? Well you need to like Nelson Sauvin that's for sure, and I do. Tempered with the tropical fruits of Galaxy and a stiff malt backbone from the Munich and Melanoidin malts I find it to be quite balanced and the mouthfeel you get from the Vermont yeast just can't be beat.

I kegged my Flagstaff IPA today after 2 weeks in the fermenter. A very healthy 86% attenuation gave an FG of 1.006 and a final ABV of 5.0%. This was the last use of the OYL-052 yeast that I've been overbuilding for the last four brews and next it's time for a couple of lagers using Wyeast 2308 then I'll be back on the Vermont strain for some ales.

Kwik-Clear finings were added to the keg, headspace purged with 5x15psi and I'll now leave it on gas for a couple of weeks before trying it. The sample jar tasted really, really good. I'm looking forward to tucking into this one over the Christmas break.

Kwik-Clear finings were added to the keg, headspace purged with 5x15psi and I'll now leave it on gas for a couple of weeks before trying it. The sample jar tasted really, really good. I'm looking forward to tucking into this one over the Christmas break.

Am I correct in thinking that you don't have a trub filter in your boiler? And that you just leave it to sit for an hour before draining through the tap?

Cheers. Tom

Cheers. Tom

I drain the entire boiler into the fermenter as soon as I've brought it in and sanitised it (I keep it out of the room while preparing the wort because of the risk of contamination from grain dust). As far as trub removal before that goes, I bag my pellet hops and skim off the crud that gathers on the surface during the boil. The reason I drain the lot is to maximise the use of my fermenter which has a rather large 4 litre dead space below the outlet valve which I'd rather fill with trub than beer.Am I correct in thinking that you don't have a trub filter in your boiler? And that you just leave it to sit for an hour before draining through the tap?

I've always been a bit inpatient once the boil is done. As soon as the wort is cool enough I open the tap to the fermenter. All my hops (pellets), including flame out, go in a fine mesh spider that gets lifted and dunked many times during cooling. I used to have a bazooka on the tap but got fed up with it blocking so got the spider.

I've seriously neglected my grain brewing of late so when I clear the short date kits I've got I'll dig the trusty Ace out and fire it up again.

I'm sure I read on one of your posts that you wait about 60 mins to allow things to settle before transfer tho?

Cheers. Tom

I've seriously neglected my grain brewing of late so when I clear the short date kits I've got I'll dig the trusty Ace out and fire it up again.

I'm sure I read on one of your posts that you wait about 60 mins to allow things to settle before transfer tho?

Cheers. Tom

Me too on the quick transfer after the boil. It's partly because I'm a bit worn out by then and am trying to get it done and also I don't like leaving wort sitting around. I like to get it in the brew fridge and down to pitching temperature as soon as I can, which could be just an hour or two for an ale or the next morning for a lager.I've always been a bit inpatient once the boil is done. As soon as the wort is cool enough I open the tap to the fermenter. All my hops (pellets), including flame out, go in a fine mesh spider that gets lifted and dunked many times during cooling. I used to have a bazooka on the tap but got fed up with it blocking so got the spider.

I've seriously neglected my grain brewing of late so when I clear the short date kits I've got I'll dig the trusty Ace out and fire it up again.

Cheers. Tom

Touch wood I don't think it was me that said that.I'm sure I read on one of your posts that you wait about 60 mins to allow things to settle before transfer tho?[

...and a duplicate post of my Outback Ale No.2 from the what are you drinking tonight thread just so I keep track of what I've done. I did the same grain bill for my Flagstaff IPA that's just gone into the keg today and definitely have high hopes for that one. The keg's set at around 15psi which seems a bit high given the 11C temperature in the garage at the moment but subjectively the amount of carbonation I get at that pressure seems 'about right' for an ale.

Touch wood I don't think it was me that said that.

Just found it. Post #7 on page 1 of this thread

Knew I'd seen it somewhere

Chilled down to 27C with the immersion chiller, gave it 60 minutes standing time to let the protofloc drop out the gunk then drained to the SS fermenter and stuck it in the fridge for the last bit of cooling before pitching.

Cheers. Tom

Hoisted by my own petard! I don't do that stand any more, it achieved nothing :)Just found it. Post #7 on page 1 of this thread

Knew I'd seen it somewhere

Cheers. Tom

You do get some really clear wort though. So jealous.

The hot/cold break obviously don't cause any issues then. Break material is supposed to be very good yeast nutrient but it looks horrible so I don't like it going into my fermenter

Cheers Tom

The hot/cold break obviously don't cause any issues then. Break material is supposed to be very good yeast nutrient but it looks horrible so I don't like it going into my fermenter

Cheers Tom

I'm sure there are many factors that help bring about a clear beer, luck being one of them. That said I've had no trouble getting a crystal clear beer as long as I use protofloc. I don't cold crash, and although I try and leave the very bottom of the trub in the boiler most of it goes in the fv. I reckon water quality and luck works for me.

There's so many variables, it's hard to pinpoint the cause I suppose.

Once I get the Ace up and running again I'll have to try your mainline bitter. Superb looking pint, some other tasty looking formulations in this thread too.

Query......... Do you keep a stock of base malt then buy the smaller weighments and hops as a "kit" from the likes of the malt miller?

I've had a 25kg sack of Bairds pale opened for over 12 months, I hope it's still usable. Been kept dry and sealed so fingers crossed

Cheers. Tom

Once I get the Ace up and running again I'll have to try your mainline bitter. Superb looking pint, some other tasty looking formulations in this thread too.

Query......... Do you keep a stock of base malt then buy the smaller weighments and hops as a "kit" from the likes of the malt miller?

I've had a 25kg sack of Bairds pale opened for over 12 months, I hope it's still usable. Been kept dry and sealed so fingers crossed

Cheers. Tom

I can vouch for the mainline, brewed it twice. Lovely.

Today I brewed a repeat of my Bavarian-style pils that I'm calling Kristall Pilsner this time around. Here's the recipe:

Although the recipe states Ireks pilsner malt it's actually 50/50 Ireks and Weyermann Bohemian because I can't get Ireks any more since it mysteriously disappeared from the Geterbrewed site without warning or explanation. The Weyermann Bo-Pils (not floor malted) has a great reputation so I've got no problem switching over to it.

I got started at about half ten this morning; a bit late for me because I got back from hols at 1am and had to go out to buy the Ashbeck water this morning before I could get started. I measured out the grain while the water was heating:

I crushed it as strike temperature was getting close:

No problems with the mash, boil and wotnot and I managed to chill down to 22C with 60 litres of water before transferring to the fermenter.

It's now in the brew-fridge to get it down to 12C or lower before I decant and pitch the 2.3 litre Wyeast 2308 starter that I created 2 weeks ago before I went away. It's been sitting in the fridge since then so should not have lost many cells.

OG was 1.043 against a predicted 1.044. If this finishes around 1.006 as everything I ever brew seems to do then it'll be 4.9%

The plan is for a few days at 10C until I notice activity starting to slow then I'll bring it up to 16C and leave it there for a total of 3 weeks before kegging.

Code:

Recipe Specifications

--------------------------

Batch Size (fermenter): 24.00 L

Estimated OG: 1.044 SG

Estimated Color: 6.9 EBC

Estimated IBU: 28.8 IBUs

Brewhouse Efficiency: 76.00 %

Est Mash Efficiency: 76.7 %

Boil Time: 60 Minutes

Water profile: Ca:28, Mg:3, Na:9, SO4:10, Cl:44, HCO3:25

Estimated mash pH: 5.30

Ingredients:

------------

Amt Name Type %/IBU

29.63 L Tesco Ashbeck Water -

3.30 ml Lactic Acid (Mash) Water Agent -

1.20 g Calcium Chloride (Mash) Water Agent -

4.14 kg IREKS Pilsner Malt (3.5 EBC) Grain 90.0 %

0.23 kg IREKS Crystal Maple (3.5 EBC) Grain 5.0 %

0.23 kg IREKS Munich Malt (20.0 EBC) Grain 5.0 %

0.30 g Calcium Chloride (Sparge) Water Agent -

0.20 ml Lactic Acid (Sparge) Water Agent -

18.00 g Magnum [11.00 %] - Boil 60.0 min Hop 22.9 IBUs

12.00 g Tettnang [3.00 %] - Boil 15.0 min Hop 2.1 IBUs

17.00 g Tettnang [3.00 %] - Boil 10.0 min Hop 2.1 IBUs

1.00 Items Whirlfloc Tablet (Boil 7.0 mins) Fining -

25.00 g Tettnang [3.00 %] - Boil 5.0 min Hop 1.7 IBUs

1.0 pkg Munich Lager (Wyeast Labs #2308) Yeast -

Mash Schedule: Single Infusion, Medium Body, Batch Sparge

Total Grain Weight: 4.59 kg

----------------------------

Name Description Step Temperat Step Time

Mash In Add 24.63 L of water at 69.3 C 66.0 C 60 min

Sparge: Dunk sparge with 5 L of 75C waterAlthough the recipe states Ireks pilsner malt it's actually 50/50 Ireks and Weyermann Bohemian because I can't get Ireks any more since it mysteriously disappeared from the Geterbrewed site without warning or explanation. The Weyermann Bo-Pils (not floor malted) has a great reputation so I've got no problem switching over to it.

I got started at about half ten this morning; a bit late for me because I got back from hols at 1am and had to go out to buy the Ashbeck water this morning before I could get started. I measured out the grain while the water was heating:

I crushed it as strike temperature was getting close:

No problems with the mash, boil and wotnot and I managed to chill down to 22C with 60 litres of water before transferring to the fermenter.

It's now in the brew-fridge to get it down to 12C or lower before I decant and pitch the 2.3 litre Wyeast 2308 starter that I created 2 weeks ago before I went away. It's been sitting in the fridge since then so should not have lost many cells.

OG was 1.043 against a predicted 1.044. If this finishes around 1.006 as everything I ever brew seems to do then it'll be 4.9%

The plan is for a few days at 10C until I notice activity starting to slow then I'll bring it up to 16C and leave it there for a total of 3 weeks before kegging.

Hi Tom I to have been neglecting Ag reason I brew outside and its bloody cold, I have been pimping wilko kits the best one so far is the dark velvet stout, first warmish day the Klarstein is coming outI've always been a bit inpatient once the boil is done. As soon as the wort is cool enough I open the tap to the fermenter. All my hops (pellets), including flame out, go in a fine mesh spider that gets lifted and dunked many times during cooling. I used to have a bazooka on the tap but got fed up with it blocking so got the spider.

I've seriously neglected my grain brewing of late so when I clear the short date kits I've got I'll dig the trusty Ace out and fire it up again.

I'm sure I read on one of your posts that you wait about 60 mins to allow things to settle before transfer tho?

Cheers. Tom