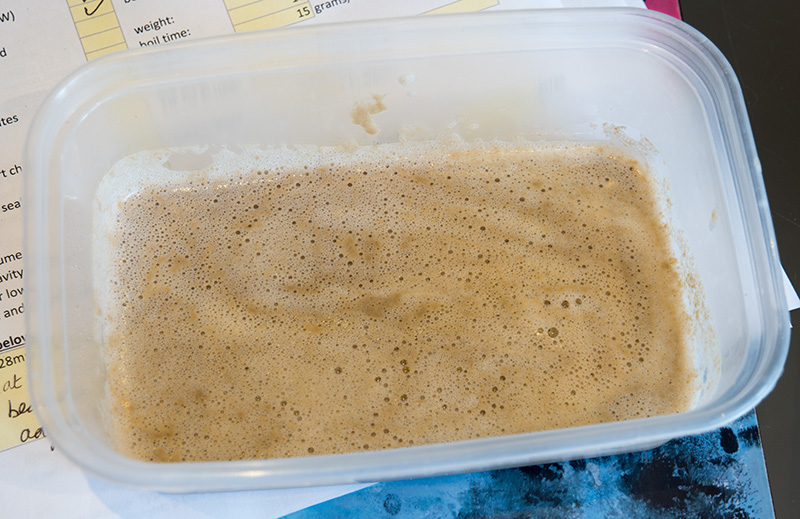

Funny you should mention chocolate because a lady I know who doesn't drink beer had a sip and immediately said "chocolate". It's turning out to be a decent beer but more of a mild than a porter due to the OG shortfall.I have been cold steeping for ages but i always reduced the liquid and added it around the start of the boil. Last time i added it with the chiller and noticed i got a lot more flavour. The beer actually tastes of chocolate which really amazed me. Seems i was doing it wrong before. You are right about the efficiency, last brew i had to top up with spraymalt which i never do. Also large amounts of adjuncts always mess with my numbers.

What sort of bag are you using? The one i am using now is ok but needs to be bigger.

I got the BIAB bag on Ebay. I can't see the same listing any more. It used to show a heavy weight dangling in the bag. There's a listing now showing a bloke in a white coat with blue gloves where the bag looks identical to the one I have.