EskiBrew

Regular.

Some time ago I bought a second hand cask breather (cask aspirator) to use with my cornie setup and beer engine. It looked reasonable from the outside but I decided I wanted to dismantle it to check inside for any problems - as you will see, I'm glad I did :sick:

This is mainly a picture based How-to because it's pretty clear what to do from looking at the pictures but for those who may be unsure why they need a cask breather and/or how a cask breather works, here's a summary:

As you draw beer from the cornie using the beer engine, you need to let air in to prevent a vacuum. Unless you intend drinking the entire contents of the cornie in a few days, letting plain air in is not a great idea because the beer will start to oxidise. The idea therefore is to allow CO2 to be drawn in instead of air.

One option is to connect the cornie to a regulator and apply just a few PSI of positive pressure. This will work if you have a check valve in the connection to the beer engine because a check valve is capable of holding back a small pressure of liquid. Without a check valve, any positive pressure into the cornie is likely to cause a constant dribble of beer or at the best a drip from the beer engine.

The other option is to apply CO2 at atmospheric pressure only and this is where the cask breather comes in. As liquid is sucked out of the cornie, it causes a small vacuum on the gas inlet connection. The vacuum causes a diaphram to move and press against a lever arm of a gas inlet valve. This small movement allows CO2 to flow into the cornie until the vacuum is gone at which point the diaphram moves back to the resting position and stops pressing on the lever arm so the CO2 stops flowing. Since one side of the diaphram is exposed to atmospheric pressure, the CO2 supplied to the cornie will also be at atmospheric pressure and will therefore not dissolve into and carbonate your beer.

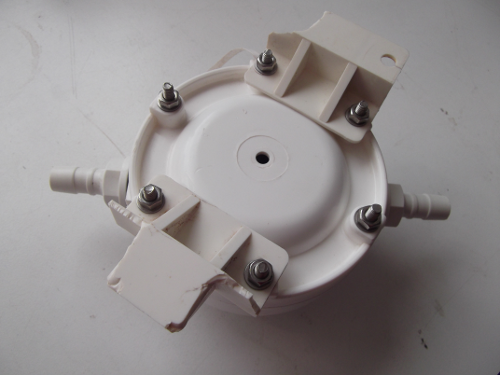

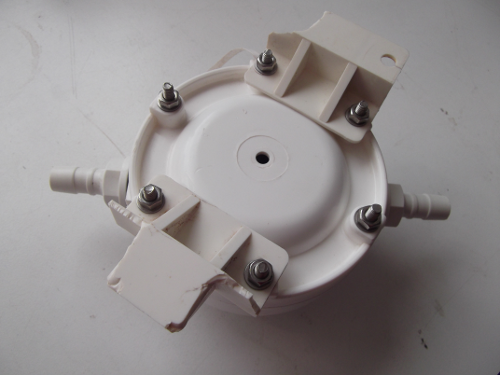

Top view showing the pressure relief valve (the lump on top). If pressure builds up in your cornie, this will allow it to release without damaging the cask breather.

Bottom view showing the atmospheric vent. This allows atmospheric air pressure to reach the back side of the diaphram.

Dismantled - Yuk!

Diaphram - check carefully for perishing and/or splits

Demand valve - either apply a few PSI of CO2 or blow into the CO2 inlet and check the valve works by allowing a flow of gas when lightly deflecting the lever arm

Pressure relief valve with cover removed (after cleaning out gunk)

Pressure relief valve after cleaning under seal

All cleaned and ready for reassembly

This is mainly a picture based How-to because it's pretty clear what to do from looking at the pictures but for those who may be unsure why they need a cask breather and/or how a cask breather works, here's a summary:

As you draw beer from the cornie using the beer engine, you need to let air in to prevent a vacuum. Unless you intend drinking the entire contents of the cornie in a few days, letting plain air in is not a great idea because the beer will start to oxidise. The idea therefore is to allow CO2 to be drawn in instead of air.

One option is to connect the cornie to a regulator and apply just a few PSI of positive pressure. This will work if you have a check valve in the connection to the beer engine because a check valve is capable of holding back a small pressure of liquid. Without a check valve, any positive pressure into the cornie is likely to cause a constant dribble of beer or at the best a drip from the beer engine.

The other option is to apply CO2 at atmospheric pressure only and this is where the cask breather comes in. As liquid is sucked out of the cornie, it causes a small vacuum on the gas inlet connection. The vacuum causes a diaphram to move and press against a lever arm of a gas inlet valve. This small movement allows CO2 to flow into the cornie until the vacuum is gone at which point the diaphram moves back to the resting position and stops pressing on the lever arm so the CO2 stops flowing. Since one side of the diaphram is exposed to atmospheric pressure, the CO2 supplied to the cornie will also be at atmospheric pressure and will therefore not dissolve into and carbonate your beer.

Top view showing the pressure relief valve (the lump on top). If pressure builds up in your cornie, this will allow it to release without damaging the cask breather.

Bottom view showing the atmospheric vent. This allows atmospheric air pressure to reach the back side of the diaphram.

Dismantled - Yuk!

Diaphram - check carefully for perishing and/or splits

Demand valve - either apply a few PSI of CO2 or blow into the CO2 inlet and check the valve works by allowing a flow of gas when lightly deflecting the lever arm

Pressure relief valve with cover removed (after cleaning out gunk)

Pressure relief valve after cleaning under seal

All cleaned and ready for reassembly