karloz

Member

So after using kits for a while, I decided to attempt AG. Not wanting to spend a fortune, I thought I would build my own equipment and upgrade as I go.

I am a total beginner at this so I watched a lot of videos and set at it. Yesterday I completed my first AG and it seemed to go ok (apart from the few lessons learnt found here http://www.thehomebrewforum.co.uk/showthread.php?t=71663)

Boil kettle:

Equipment used:

30l FV

2x Tesco value kettles (ã6 each)

15mm Compession tank connector (ã2.32 toolstation)

Copper pipe (B&Q ã6.24 3m x 15mm - This is enough for the mash tun too)

Ball valve to fit 15mm copper pipe (I liberated mine from work)

40mm & 20mm Hole saw (these were my measurements)

Sandpaper

PTFE tape (use it on every thread throughout)

First I took the kettles to pieces and removed the elements to fit. I measured the elements and found I needed a 40mm hole saw. There is a small metal disc inside that has to be removed, otherwise when it hits boiling it will cut off.

I then drilled, sanded and fitted them:

EDIT: I had a few problems with leaks from the kettle elements when in place. The wall of the kettle was slightly thicker than the FV. I ended up doubling the seals with some spare bits I had kicking about.

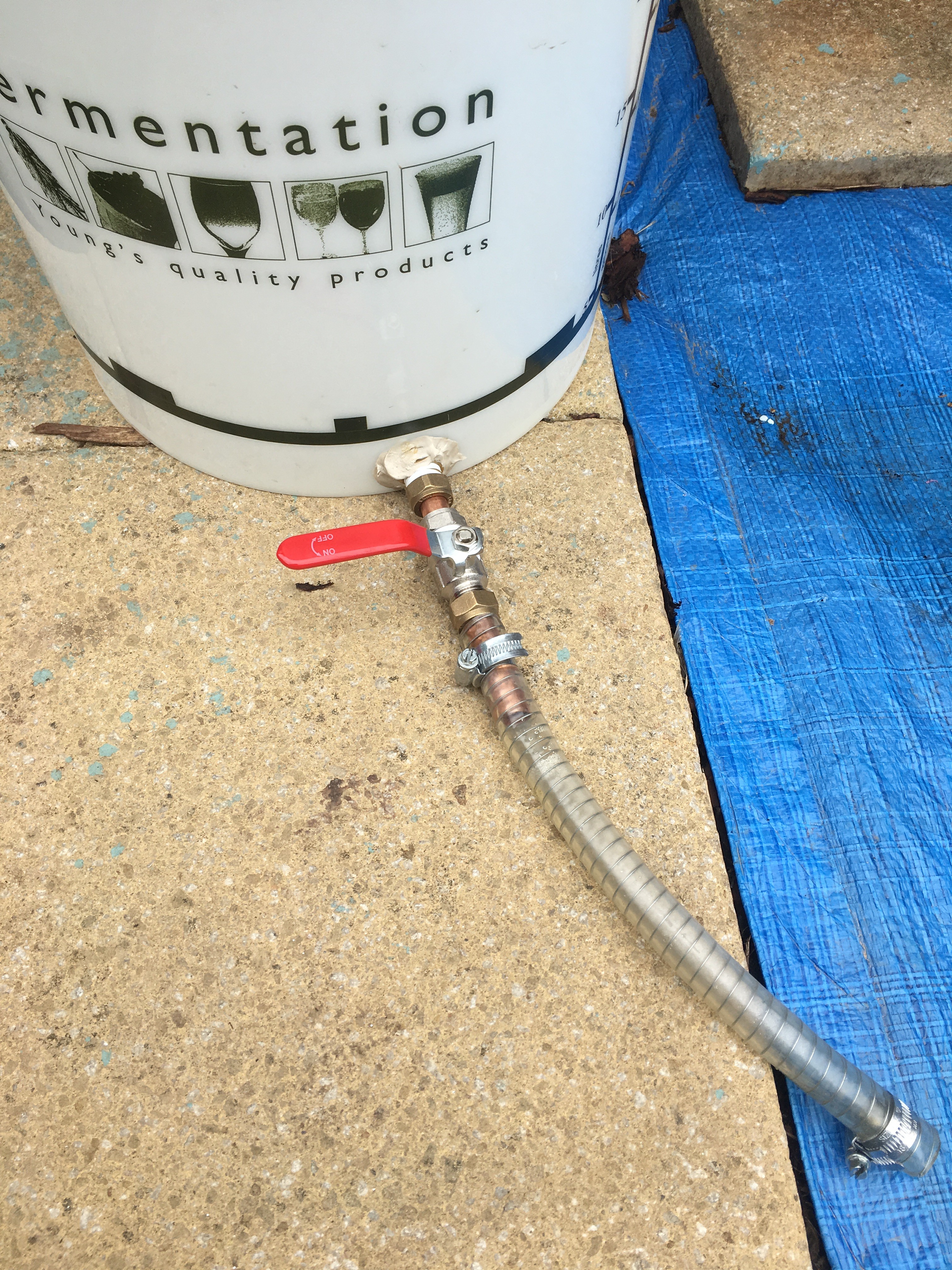

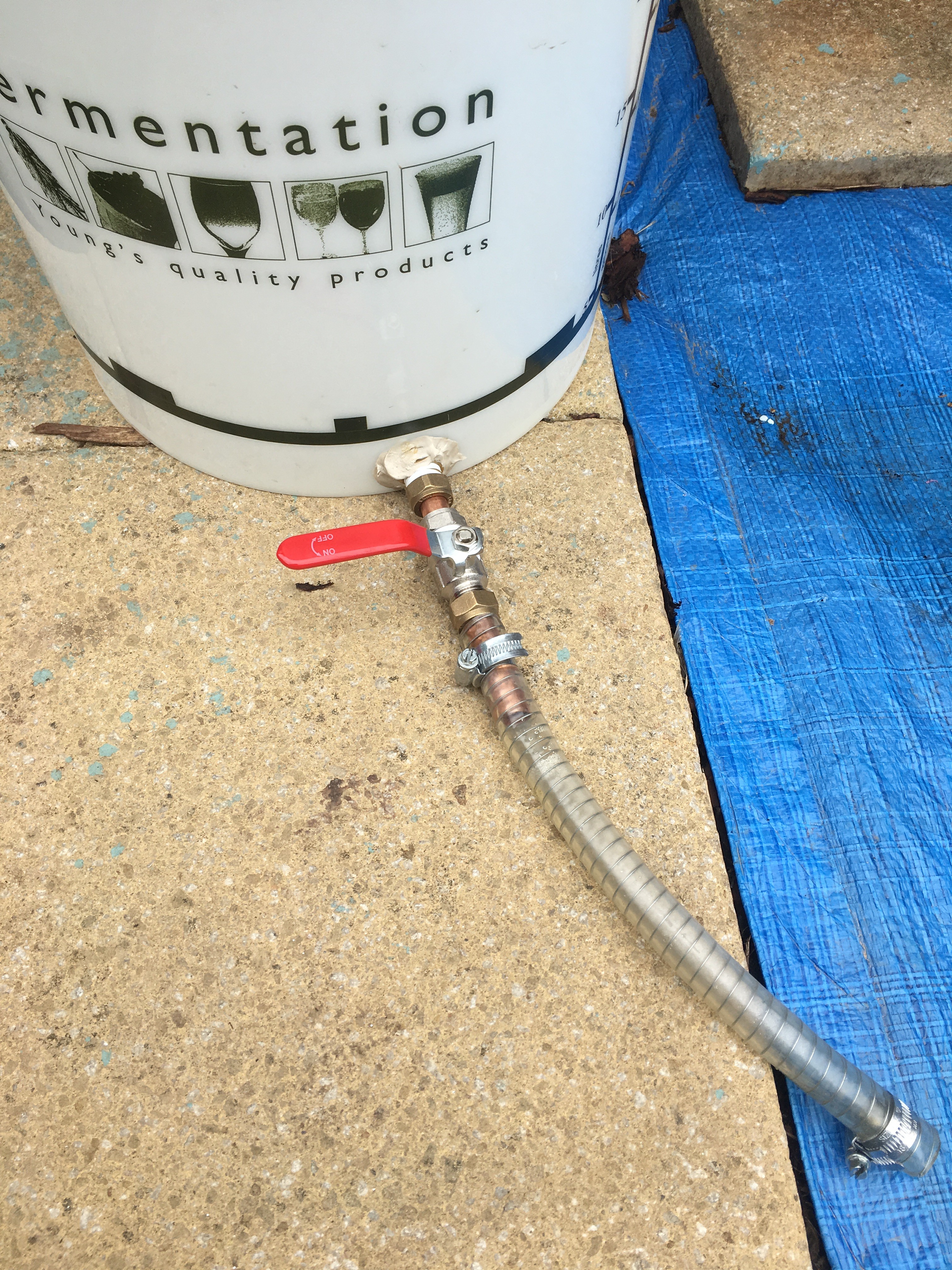

I then drilled a 20mm hole, sanded and fitted the tank connector, small length of copper pipe to a valve and another piece of copper pipe (followed by jubilee clipped hose)

I took a small length of copper pipe for a 'false bottom', however this proved a problem so I am going to change this to a 'flexible tap connector' with the rubber hose taken out of the middle (just leaving the mesh)

Mash Tun

Equipment used

12l Cool box (ã9 poundstretcher) I may get a bigger size though

15mm Compession tank connector (ã2.32 toolstation)

Ball valve to fit 15mm copper pipe

15mm Copper pipe 't' pieces and elbows

Copper pipe from above

16mm & 20mm drill bits/hole saws

1mm drill bit or similar

Firstly, I drilled through the bottom corner and fitted the tank connector, connected to ball valve (same as for boil kettle). I did have to make a bigger hole on the outside to fit a spanner in.

I then created my inner piping for the grain bed and drilled lots of small holes in it. This just slots into the tank connector. I didn't weld it together for easy cleaning:

Next, Sparge arm. I drilled a 16mm hole in the top of my cool box and poked a small length of copper pipe through.

Inside, push fitted together i created the sparge arm by drilling 1mm holes.

Wort chiller

Equipment used:

Wednesbury copper compression tube 8mm x 10m (ã14.78 B&Q)

Hose pipe

Jubilee clips

Easy one. Just wrapped the copper pipe around a paint tin and connected the hose pipe to each end.

Final set up...

I hope this is of some use to someone...

I am a total beginner at this so I watched a lot of videos and set at it. Yesterday I completed my first AG and it seemed to go ok (apart from the few lessons learnt found here http://www.thehomebrewforum.co.uk/showthread.php?t=71663)

Boil kettle:

Equipment used:

30l FV

2x Tesco value kettles (ã6 each)

15mm Compession tank connector (ã2.32 toolstation)

Copper pipe (B&Q ã6.24 3m x 15mm - This is enough for the mash tun too)

Ball valve to fit 15mm copper pipe (I liberated mine from work)

40mm & 20mm Hole saw (these were my measurements)

Sandpaper

PTFE tape (use it on every thread throughout)

First I took the kettles to pieces and removed the elements to fit. I measured the elements and found I needed a 40mm hole saw. There is a small metal disc inside that has to be removed, otherwise when it hits boiling it will cut off.

I then drilled, sanded and fitted them:

EDIT: I had a few problems with leaks from the kettle elements when in place. The wall of the kettle was slightly thicker than the FV. I ended up doubling the seals with some spare bits I had kicking about.

I then drilled a 20mm hole, sanded and fitted the tank connector, small length of copper pipe to a valve and another piece of copper pipe (followed by jubilee clipped hose)

I took a small length of copper pipe for a 'false bottom', however this proved a problem so I am going to change this to a 'flexible tap connector' with the rubber hose taken out of the middle (just leaving the mesh)

Mash Tun

Equipment used

12l Cool box (ã9 poundstretcher) I may get a bigger size though

15mm Compession tank connector (ã2.32 toolstation)

Ball valve to fit 15mm copper pipe

15mm Copper pipe 't' pieces and elbows

Copper pipe from above

16mm & 20mm drill bits/hole saws

1mm drill bit or similar

Firstly, I drilled through the bottom corner and fitted the tank connector, connected to ball valve (same as for boil kettle). I did have to make a bigger hole on the outside to fit a spanner in.

I then created my inner piping for the grain bed and drilled lots of small holes in it. This just slots into the tank connector. I didn't weld it together for easy cleaning:

Next, Sparge arm. I drilled a 16mm hole in the top of my cool box and poked a small length of copper pipe through.

Inside, push fitted together i created the sparge arm by drilling 1mm holes.

Wort chiller

Equipment used:

Wednesbury copper compression tube 8mm x 10m (ã14.78 B&Q)

Hose pipe

Jubilee clips

Easy one. Just wrapped the copper pipe around a paint tin and connected the hose pipe to each end.

Final set up...

I hope this is of some use to someone...

I've been told its a bit flashy haha.

I've been told its a bit flashy haha.