After over three years of researching, designing, testing and building my new brewery is finished! I set out with the following principles:

It had to be shiney

Brew-length approx. 30litres (3 crates, a crate and a corney, or a big and a small corney)

Easy to use and clean

Computer control where it matters, ie to improve accuracy and consistency (no gratuitous computer control and automation)

As much as possible to be homemade

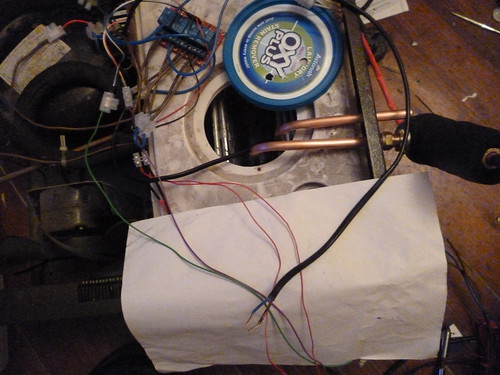

I used Bergland type stock pots and used an arduino to provide the temperature control. The HLT is 70l, the mash tun is 33l, the boiler is 50l and the fermenter has a capacity of 48l. I use a HERMS to control mash temperature. The arduino is linked to computer which enables a nicer display.

The finished brewery

The HLT

Short leads to make cleaning easier

The mash tun

The heat exchanger

Sparging (sample tap for measuring samples of first and last runnings)

The boiler

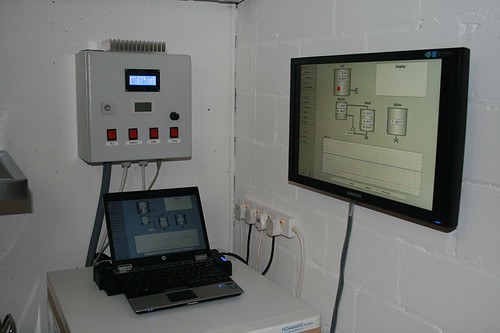

The control box and PC screen

The fermenting fridge

The controller has two parts, the arduino which does the actual control bit and the software which is used to manage the settings in the arduino and provide a nice display. The temperature probes are the DS18B20 type and there are 5 (HLT, heat exchanger, 2 in the mash tun and the boiler). There is a float switch in the HLT to stop the it running dry while sparking (done that before...). The pump is a 12V one from MrLard, and the plan is to add speed control using a transistor (I couldn't get this working so I left it off for the moment so I can brew some beer and rebuild stock...). Two SSRs control power to the elements. Additional switches on the control box control power to the SSRs as an additional level of control over power to them. The pot is to control pump speed.

Because I live in a rented house it had to be able to run off standard mains sockets so there are two power leads which provide power and can be plugged into different sockets in the house. One powers the elements, the other everything else. The arduino software is written in such a way that only one element can run at a time, with the heat exchanger getting priority. There is a silly little display to monitor voltage and current consumption of the elements.

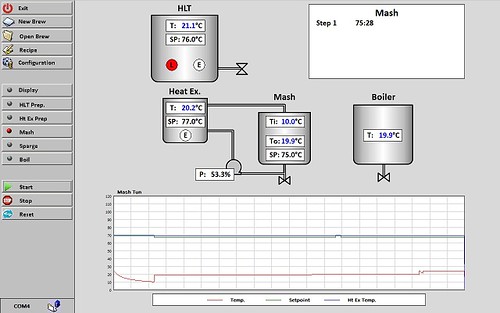

There are a number of different control modes:

Temperature display only

HLT. Prep. used to bring the liquor up to temp.

Heat Exchanger Prep. to get the HERMS ready for use

Mashing which controls mash and heat changer temp. And maintains HLT temp

Sparking, similar to above but showing different temps on the control box display

Boil which only displays boiler temp. on the control box display

The control mode and temperatures are all set from the PC software, which is written in C++. It can import beerxml files (saved from beersmith) with all the recipe data and communicates with the arduino via USB. Temperature data is written to a CSV file for later use if needed.

This is the PC screen