Luckly enough to be handed a bag with 1kg of Bere.

Bere is not exactly the same as modern barley. http://www.agronomy.uhi.ac.uk/html/Bere_history.htm

Stage 1

Malting

First I soaked the grain for two hours in plenty of Luke warm water, we don't want the water to go stale.

After the soak I set it out in a tray and left that it the hall at about 16degC for about eight hours, mixing the grain every couple of hours giving each grain time to breath.

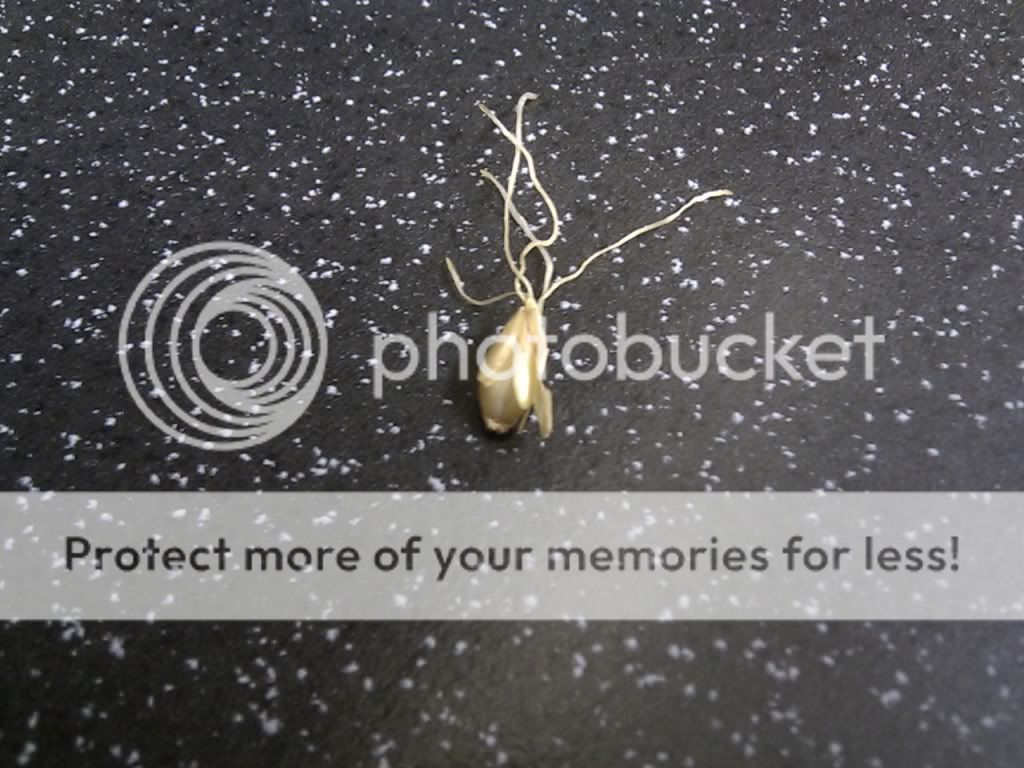

Repeated this three times until the roots were about three time the length of the grain and the shoot inside the grain was at least three quarters the length of the grain. Just split a few grains to see the length.

Next I needed to dry the germinated grain. Must ensure it does not get above about 50degC or I will loose the enzymes we need for the mash tun.

First attempt was to use the fermentation fridge set to 35,

problem was that with the door cracked open to let the moisture out it was too cool so now it's in the kitchen oven at min with the door held open with a wooden spoon.

This should be done in under 24hrs.

I'll need a drink while I wait.

A simple IPA from the beer pump.

I just use some of Vossy's tube to connect the polycube to the pump. I find this keeps the beer fresh for two weeks fine.

A bit basic, but the garage is cool and it works.

If there's interest I'll update this post all the way through to the first taste of the finished beer.

My intention is to use EKG as a full bittering hop without any flavour or aroma additions to see if I get a unique flavour from the Bere. Will keep the ABV quite low. Going to roast about 5% of grain to get a crystal to up the sweetness.

Cheers.

Neil

Bere is not exactly the same as modern barley. http://www.agronomy.uhi.ac.uk/html/Bere_history.htm

Stage 1

Malting

First I soaked the grain for two hours in plenty of Luke warm water, we don't want the water to go stale.

After the soak I set it out in a tray and left that it the hall at about 16degC for about eight hours, mixing the grain every couple of hours giving each grain time to breath.

Repeated this three times until the roots were about three time the length of the grain and the shoot inside the grain was at least three quarters the length of the grain. Just split a few grains to see the length.

Next I needed to dry the germinated grain. Must ensure it does not get above about 50degC or I will loose the enzymes we need for the mash tun.

First attempt was to use the fermentation fridge set to 35,

problem was that with the door cracked open to let the moisture out it was too cool so now it's in the kitchen oven at min with the door held open with a wooden spoon.

This should be done in under 24hrs.

I'll need a drink while I wait.

A simple IPA from the beer pump.

I just use some of Vossy's tube to connect the polycube to the pump. I find this keeps the beer fresh for two weeks fine.

A bit basic, but the garage is cool and it works.

If there's interest I'll update this post all the way through to the first taste of the finished beer.

My intention is to use EKG as a full bittering hop without any flavour or aroma additions to see if I get a unique flavour from the Bere. Will keep the ABV quite low. Going to roast about 5% of grain to get a crystal to up the sweetness.

Cheers.

Neil