See this post on other thread about first test of HERMS system.

viewtopic.php?p=209171#p209171

First time out with my new HERMS system. I struggled with the flow rate (0.6-0.9L/m) and didn't really achieve a clear wort. I also started with too cool a mash (60 deg) which I was unable to get up to a reasonable mash temperature (as measured at the outflow) for over an hour. My efficiency was definitely down though I've not worked out exactly how much, probably around 65%.

The brew fermented down OK and tastes good and is clear.

Several things to try next time.

1. thinner mash (I usually use just over 2:1 ratio because my mash tun is a bit too small TBH) therefore, less grain.

2. let mash settle 10mins before pumping.

3. Invest in a false bottom, as currently my strainer is a 900mmx15mm SS braided hose with the hose cut out.

4. be more careful with the strike temperature and initial mixing.

Its all part of the experimentation.

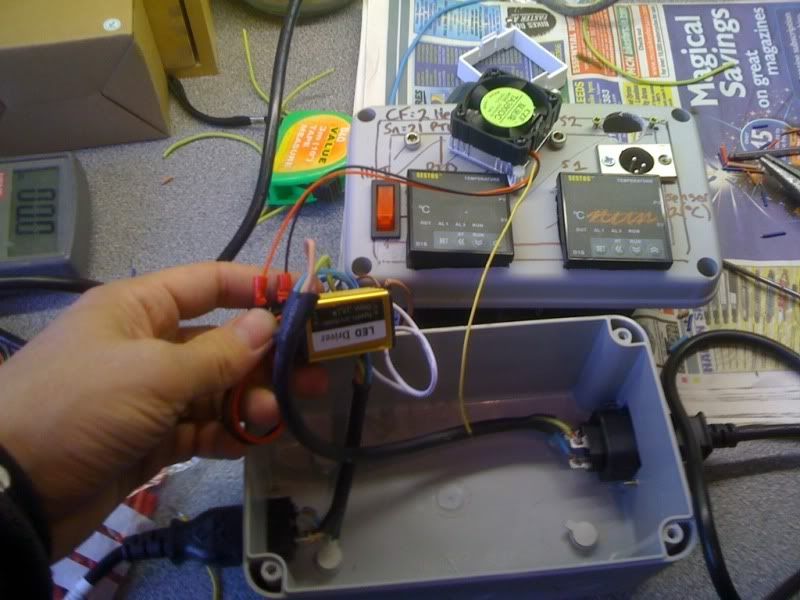

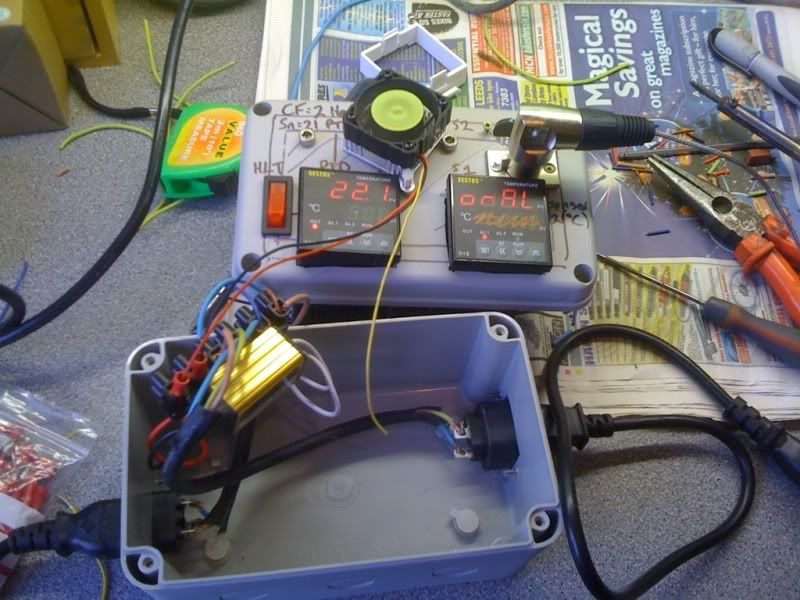

I was very pleased how the actual HE and PID performed. It's outflow was bang on the whole time, just the flow rate was low.

Second test, on 22Jan12 went much better.

1. 9.3Kg grain and ~26L liquor.

2. stirred and adjusted to 64degrees for 10mins before starting pump

3.continued with current strainer. Achieved a measured 2.2L/min flow rate without pumping at maximum with no sticking problems and clear wort.

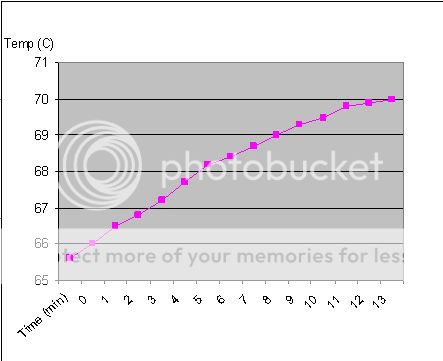

Additionally, now the HERMS was working properly, I conducted an experiment that Springer and I had been discussing. I compared mash inlet and outlet temperatures over time for the temperature increase at âmash outâ. I set the PID for 70 deg C and monitored the increase in outflow temperature. The flow rate was 2.2L/min and circulating volume around 26L (not precisely measured unfortunately). 9.3Kg stationary phase (grain).

TIME Mash exit T (Celsius)

0 65.6

1 66

2 66.5

3 66.8

4 67.2

5 67.7

6 68.2

7 68.4

8 68.7

9 69

10 69.3

11 69.5

12 69.8

13 69.9

14 70

Will knock up a graph somehow. :geek: I did a video but it will take ages before I get round to editing it.

Excel is rubbish for graphs.

So, Iâll check it again but I guessed that the time to circulate the entire volume through the HEX at the desired temperature, plus some (25%) of that time to heat the stationary phase would be in the right ball park.

Rough rule of thumb from this experiment in this system is time to increase from 65 to 70 is, the time to circulate full volume x 116%. I will test how repeatable this is. There will obviously be a proper physics formula involving temperature differences and specific heat capacities. Iâll leave that to someone with the time and inclination to work it out.

Overall, the brew went well and achieved around 80% efficiency including losses to deadspace and hops etc.