I haven't been on for a while beause I haven't had much interesting to say apart from a spoilt brew (left too long in the fermentor) due to work pressures, DIY and a house move.

I did an AG the other day and I was yet again told off for brewing in the house (even though the missus was away) So I have been making room in the shed where I shall install the 100L setup I have. Being a small shed there are lots of issues with height which requires motors to Tx the liquor etc so I got thinking and being a bit of a Pi geek I set about designing a Pi controlled brewery.

I noticed there were people who had done either a PID or a fermentor Temp controller and the only other automated homebrew solution I could find was going to cost thousands. I dont beleive in commercialising something the uses a raspberry pi, the ethos is one of open source. So once complete I shall make all the designs and code available. If there is enough interest I may do a run of the ciruit boards as part of a kit but that's because it's more cost effective that way.

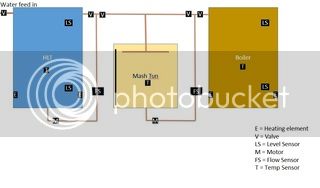

So, I knocked together a diagram of what I needed in my setup to fully control each step:

Evidently there are some limitations without spending big bucks on gravity and clarity sensors:

- manual adding of grain

- manual monitoring of first runnings clarity before switching to Boiler

- manual monitoring of the sparge gravity before stopping it

I could always program the circulation of the first runnings to the first 10L or so but I shall see how it goes before modifying the code.

To control all of the kit required will need a bespoke curcuit board. I have knocked up an initial prototype in expresspcb before realising that I needed to do it in Designspark if I wanted to get it done by someone in the UK. There seems to be a few options that will do me a one off for about £20-30 which is not too ruinous.

I have managed to source the following items for my setup:

- 4 x 40A 380VAC SSR (3-32VDC in can be run straight off the GPIO) I went over board to reduce strain on the compnents and increase the longevity

- 2 x hot liquid motors. I didn't need something that pumped liquid fast, but I do need something that can handle liquid up to 80C and above.

- 4 x float switches. Simple yet effective and vital for safety when working with high voltage

- 1 x capacitive level sensor for inside the mash tun

- 5 x 12v water valves. I tested the motor output produced enough pressure to activate. One will control the water in.

- 2 x flow meters. The idea being that I monitor the level in the mash tun as well as the flow rate out and manage the flow rate in to the tun accordingly.

- 3 x temp sensors.

- All the piping and connectors I need

I still need:

- to find a suitable water resistant box in which I can house the SSRs, the Pi, the curcuit and the 12v transformer. The SSRs do have heat sinks so I might be able to get away with plastic. Requires testing.

- to finish the curuit conversion to Gerber format.

More to follow :

I did an AG the other day and I was yet again told off for brewing in the house (even though the missus was away) So I have been making room in the shed where I shall install the 100L setup I have. Being a small shed there are lots of issues with height which requires motors to Tx the liquor etc so I got thinking and being a bit of a Pi geek I set about designing a Pi controlled brewery.

I noticed there were people who had done either a PID or a fermentor Temp controller and the only other automated homebrew solution I could find was going to cost thousands. I dont beleive in commercialising something the uses a raspberry pi, the ethos is one of open source. So once complete I shall make all the designs and code available. If there is enough interest I may do a run of the ciruit boards as part of a kit but that's because it's more cost effective that way.

So, I knocked together a diagram of what I needed in my setup to fully control each step:

Evidently there are some limitations without spending big bucks on gravity and clarity sensors:

- manual adding of grain

- manual monitoring of first runnings clarity before switching to Boiler

- manual monitoring of the sparge gravity before stopping it

I could always program the circulation of the first runnings to the first 10L or so but I shall see how it goes before modifying the code.

To control all of the kit required will need a bespoke curcuit board. I have knocked up an initial prototype in expresspcb before realising that I needed to do it in Designspark if I wanted to get it done by someone in the UK. There seems to be a few options that will do me a one off for about £20-30 which is not too ruinous.

I have managed to source the following items for my setup:

- 4 x 40A 380VAC SSR (3-32VDC in can be run straight off the GPIO) I went over board to reduce strain on the compnents and increase the longevity

- 2 x hot liquid motors. I didn't need something that pumped liquid fast, but I do need something that can handle liquid up to 80C and above.

- 4 x float switches. Simple yet effective and vital for safety when working with high voltage

- 1 x capacitive level sensor for inside the mash tun

- 5 x 12v water valves. I tested the motor output produced enough pressure to activate. One will control the water in.

- 2 x flow meters. The idea being that I monitor the level in the mash tun as well as the flow rate out and manage the flow rate in to the tun accordingly.

- 3 x temp sensors.

- All the piping and connectors I need

I still need:

- to find a suitable water resistant box in which I can house the SSRs, the Pi, the curcuit and the 12v transformer. The SSRs do have heat sinks so I might be able to get away with plastic. Requires testing.

- to finish the curuit conversion to Gerber format.

More to follow :