Well carrying on from the original brew day on the 8th . . . here is the big batch . . . Everything was going swimmingly until I discovered that I had only ordered 90g of Pacific Hallertau from Ross not 180 as I originally thought :evil: . . . but a bit of creative thinking meant the recipe was modified to.. . . . Substituting Some Nelson Sauvin for the missing Hallertau.

70l at 1.046 and 39 IBU

13120g Lager Malt

880g Carapils

28g NZ Pacific Hallertau (Pellets) 4.4% AA FWH

47g NZ Nelson Sauvin (pellets) 4.4% AA FWH

40g Hallertau Mittelfruh 4.1% AA 90 Minutes

100g Hallertau Mittelfruh 4.1% AA 15 Minutes

70g Hallertau Hersbrucker 2.8% 70C Steep.

It raises the IBU by a bit to a theoretical 41 (from 39) hardly worth worrying about.

Anyway Piccy fest The first is underletting 30L of Liquor into the mash tun

Which made for an interesting time as the 14Kg of grain decided to try and make a bid for freedom. It was a struggle initially to really stir the grain in, but with 3 minutes it was a nice thick porridge . . .even if it did nearly overflow the mash tun

But I was pretty close on mash pH and the strike heat although low was easily sorted with the HERMS . . . Happy with it being so low as I want a Crisp beer anyway.

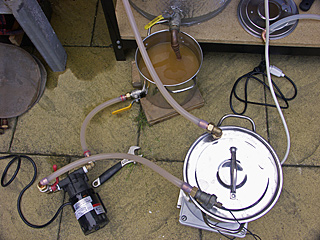

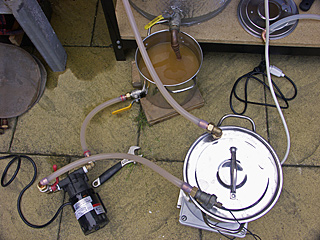

Here is the HERMS Configuration, with a close up of the Initial Recirc and the HERMS return. . . . I must invest in a better manifold some time

After 90 minutes the wort has cleared well, and is transferred to the copper (s) with the First Wort Hops. . .

Here is the sparge Manifold

The wort 'Coppering Up', the wort is allowed to boil with 'no' hops for 10 minutes until the foam subsides, then the bittering addition is added. The FWH helps to control foam production and also makes boil overs less likely . . . Never look away though . . . with 19KW under each kettle it's all too easy :lol:

75 minutes later its time to add a big handful of flavour hops (which also add a chunk of Bittering ~ 30%)

It was about this time I discovered that I had not turned off my lighter for the Bullfinch . . . Can you guess how??

"F*CK! Thats Hot!"

Just as the Boil Finished It started raining . . . Here is Toni rigging the all important Wort Protector

Wort was quickly chilled to 70C and the steep hops added and left for 20 Minutes

Then Chilling was restarted until the wort was under 25C . . . . The Chilling coils were removed for cleaning . . . and the wort tucked up ready to transfer to the FV. . . . once the rain has stopped

I'm going to watch the Grand Prix, Do some washing up and tidying up in the Kitchen where Hopefully I will warm up . . . and dry off.

70l at 1.046 and 39 IBU

13120g Lager Malt

880g Carapils

28g NZ Pacific Hallertau (Pellets) 4.4% AA FWH

47g NZ Nelson Sauvin (pellets) 4.4% AA FWH

40g Hallertau Mittelfruh 4.1% AA 90 Minutes

100g Hallertau Mittelfruh 4.1% AA 15 Minutes

70g Hallertau Hersbrucker 2.8% 70C Steep.

It raises the IBU by a bit to a theoretical 41 (from 39) hardly worth worrying about.

Anyway Piccy fest The first is underletting 30L of Liquor into the mash tun

Which made for an interesting time as the 14Kg of grain decided to try and make a bid for freedom. It was a struggle initially to really stir the grain in, but with 3 minutes it was a nice thick porridge . . .even if it did nearly overflow the mash tun

But I was pretty close on mash pH and the strike heat although low was easily sorted with the HERMS . . . Happy with it being so low as I want a Crisp beer anyway.

Here is the HERMS Configuration, with a close up of the Initial Recirc and the HERMS return. . . . I must invest in a better manifold some time

After 90 minutes the wort has cleared well, and is transferred to the copper (s) with the First Wort Hops. . .

Here is the sparge Manifold

The wort 'Coppering Up', the wort is allowed to boil with 'no' hops for 10 minutes until the foam subsides, then the bittering addition is added. The FWH helps to control foam production and also makes boil overs less likely . . . Never look away though . . . with 19KW under each kettle it's all too easy :lol:

75 minutes later its time to add a big handful of flavour hops (which also add a chunk of Bittering ~ 30%)

It was about this time I discovered that I had not turned off my lighter for the Bullfinch . . . Can you guess how??

"F*CK! Thats Hot!"

Just as the Boil Finished It started raining . . . Here is Toni rigging the all important Wort Protector

Wort was quickly chilled to 70C and the steep hops added and left for 20 Minutes

Then Chilling was restarted until the wort was under 25C . . . . The Chilling coils were removed for cleaning . . . and the wort tucked up ready to transfer to the FV. . . . once the rain has stopped

I'm going to watch the Grand Prix, Do some washing up and tidying up in the Kitchen where Hopefully I will warm up . . . and dry off.