Fore

Landlord.

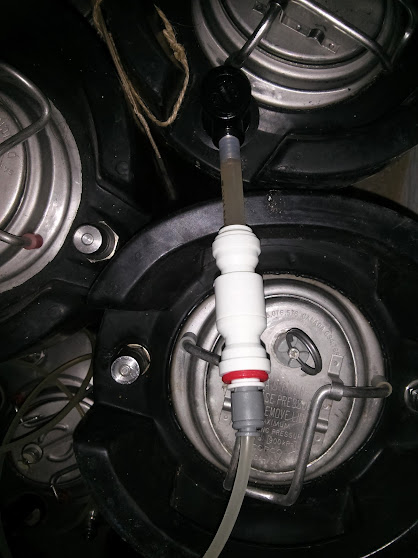

My first go at this. I'm finding the ale a little flat for my liking (possibly proper ale carbonation however), but my biggest issue is that it's all head. Well, I think I was hoping for the slow perfect pub style pour. OK, not a big deal; I've taken to pre-filling a jug and just topping up the pint. Here the issue I think... my cellar temp is 22 degrees and this is off the scale of the carbonation charts I looked at. I have it at 1 bar; the beer line is about 12 inch. I'm not ready for refrigeration just yet, and anyway, cooler weather approaches. Am I kidding myself to expect any carbonation at this temp?

Temperature aside, I find the flow rate is very high. It's useless to fully open the tap, partly why I end up with a pint of froth. I'm thinking that if I extended the beer line, then the flow rate would slow, helping maintain more of the carbonation in the beer (instead of lost in the froth). Is this thought process correct? I find it difficult to believe that the friction an extra say 50 cm line would offer would have any noticeable impact on the high flow rate I currently see, but you might tell me otherwise.

Temperature aside, I find the flow rate is very high. It's useless to fully open the tap, partly why I end up with a pint of froth. I'm thinking that if I extended the beer line, then the flow rate would slow, helping maintain more of the carbonation in the beer (instead of lost in the froth). Is this thought process correct? I find it difficult to believe that the friction an extra say 50 cm line would offer would have any noticeable impact on the high flow rate I currently see, but you might tell me otherwise.