stevela

Regular.

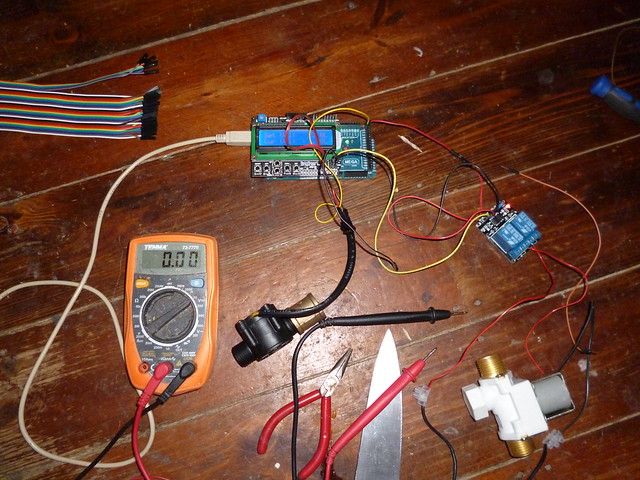

We have lift off, after about an hour of messing around I realised a few things that will probably help everyone else:

1) A 5v relay needs 5v. There is a switch on your board to change this setting.

2) Do not use digital pins 0 or 1, I have moved the solenoid in code to pin 13

3) My relay was active high, check yours with a multimeter to make sure which way round it is :)

That being said with the power supply tucked away in the cupboard I did a wet run...

[youtube:t4s2ss4h]zLwW-EbS0S0[/youtube:t4s2ss4h]

IT LIVES!

Apologies for the shaky cam, I got bored part way through and dropped the volume to 5 litres so it would end.

Time to go measure how much it thought it put in.

The only issue I have is at the end of the video you can see it resets, it appears when the solenoid closes the arduino goes through a software reset but I'm not sure why.

Now I supposed I need to start thinking about prettying this up!

1) A 5v relay needs 5v. There is a switch on your board to change this setting.

2) Do not use digital pins 0 or 1, I have moved the solenoid in code to pin 13

3) My relay was active high, check yours with a multimeter to make sure which way round it is :)

That being said with the power supply tucked away in the cupboard I did a wet run...

[youtube:t4s2ss4h]zLwW-EbS0S0[/youtube:t4s2ss4h]

IT LIVES!

Apologies for the shaky cam, I got bored part way through and dropped the volume to 5 litres so it would end.

Time to go measure how much it thought it put in.

The only issue I have is at the end of the video you can see it resets, it appears when the solenoid closes the arduino goes through a software reset but I'm not sure why.

Now I supposed I need to start thinking about prettying this up!