djcorbetto said:If you are worried about the heat, why not fit a small heat sink to it?

I don't think we should be too concerned. It's not going to catch on fire.

djcorbetto said:If you are worried about the heat, why not fit a small heat sink to it?

Fil said:Im amazed at your reservation bob, id have twisted wire back on itself thru each spade hole and secured/insulated with a bit of tape.. but im inpatient :)

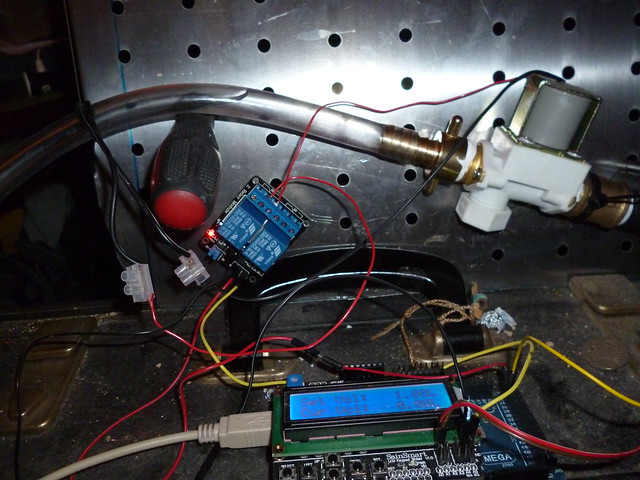

no i haven't but yes afaik the filter screen is on the in-port, as its currently plumbed up...bobsbeer said:Have you tried reversing the valve to see if it makes a difference? Although I would assume the filter is on the flow in side.

Normally closed; Inlet valve (Working water pressure: 0.02~0.8MPa), drain valve (Working water pressure: 0~0.02MPa);

Enter your email address to join: