thedrayman

Mild & Bitter

- Joined

- Dec 15, 2009

- Messages

- 206

- Reaction score

- 1

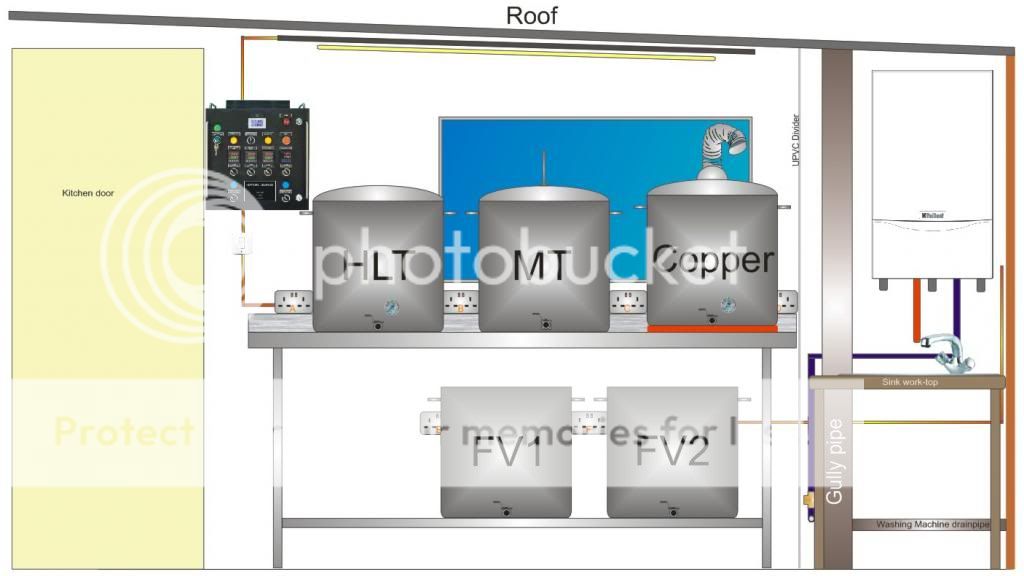

Have now got the vinyl floor down and it's starting to look (almost) like a brewery... Just waiting for my electrician friend to finish playing with the Cub Scouts (he is an 'official' not a friend of Jimmy Saville) and he can sort out the power and a light. Then a double sink unit to be fitted underneath the boiler at the end of the brewery table. I'm going to fit a uPVC cladding wall/separator at the end of the brewery table so you wont be able to see the poo-pipe or boiler/washing area.

...

...