TheMumbler

Landlord.

- Joined

- Sep 18, 2009

- Messages

- 843

- Reaction score

- 1

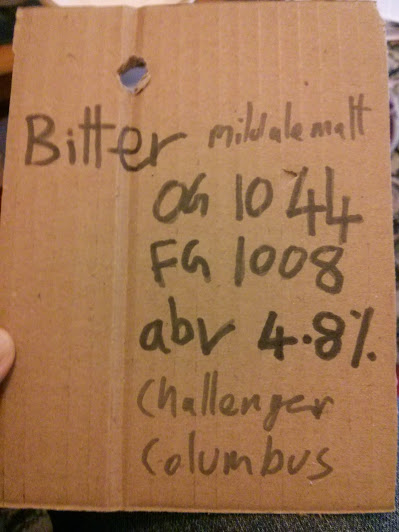

On holiday this week so brewing something which should be drinkable fairly quickly. First go at using BrewR which seems to vary a touch from qbrew which is what I use normally.

Brewlength 21L

Predicted OG 1038

Predicted FG 1009

Predicted abv 3.7%

Colour 6.9 SRM

IBU 30

2500g Mild Ale Malt

500g Flaked Barley

500g Flaked Wheat

150g Crystal

150g Carapils

Mash 66*C

1 tsp (4g gypsum)

Challenger (6.9) 60 mins

Challenger (6.9) 15 mins

Columbus (17.1) 0 mins

Yeast S04

lots of pics to follow

HLT Filled and 1/4 campden tablet added, More water, (20L) with 1/4 campden tablet ready to use in a FV, with a fresh batch of StarSan on top

Checking the alkalinity of the water. See here for a guide

0.92ml remaining, so 0.33 meq/litre x50 = 16.5 ppm CaCO3

I then calculate my water additions using the forum tool and information from United Utilities. If I am being lazy (and I usually am) I assume that my water is soft (which it will be unless we are in a drought and the source changes) and use 1tsp(~4g) gypsum in the boil and 2 tsp gypsum in the boil (~8g) for any pale ale or bitter type of thing. I would always go carefully for a dark beer as I don't have a good water profile for them.

I need 4g gypsum for the mash

8.5g gypsum, 2g salt, 2.5g epsom salts and5g CaCl for the boil. My scales aren't all that accurate at these sorts of weights so this is all "in the ballpark"

Flaked grains measured out, then in goes the crystal and carapils, finally a temp measurement showing the Mild Ale Malt

Check the water temperature is about where I want it. Check the tap on the Mash Tun (small one today) is closed (very important)

Add water to the MT and check it is where I want it in terms of temperature (I use a spreadsheet to do the calculation based on grain temp and weight and water temp and weight. In this case 73*C

Mash in, pouring and stirring is a two hands job so no pic. I pour slowly stirring well to try and avoid dough ball formation. Then give it a good stir just in case.

Then check the temperature is where I want it (66*C) put the lid on the Mash Tun and then wrap in a sleeping bag for more insulation (not shown but I'm sure you can imagine what it looks like ).

Mash for 2 hours as I have some other stuff to get on with. I then top up with hot water to stop the mash aiming to get the temp in the mid 70s. Stir and leave for another 15mins or so to let the grain bed settle down again. I then mash out.

Recirculate the first runnings until the wort is less turbid, at least so there are no bits of grain in it. I don't usually bother going for really clear wort at this stage. I use two trays from a steamer rotated round so that the holes are out of alignment to do this. Once the wort is clear enough I run the wort out, in this case into a FV but I usually run straight into the boiler for the first batch.

Once the first batch is drained out it goes into the boiler today (really not sure why I didn't run straight in). Check the hop filter is securely attached and add the boil salts before doing this. The boiler can then be switched on to get the wort heating up while I do the second batch.

I then do the second batch adding water around 80*C and leave to settle again. I then repeat the run off process described above. A few jugs worth of wort recirculated before running off.

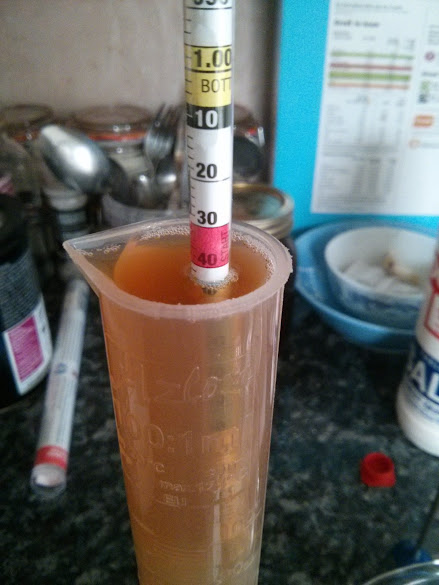

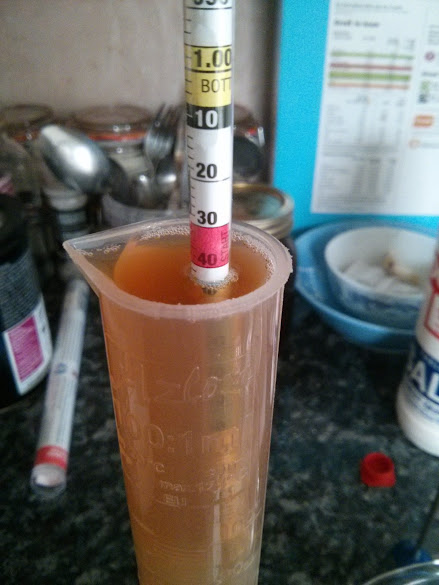

When I have my full volume of wort in the boiler I take a preboil gravity reading to check that my hopping is going to be OK. I usually chill this down to around 30*C so that the adjustment for temperature isn't too wobbly

Today I have 1036@ 30*C so around 1039. I am going to be stronger than I was aiming for. Looking at my IBU estimate I'm happy that being a bit less bitter is going to be OK so I don't adjust. You can do this by going back to your software and adjusting the efficiency until the predicted OG is what I estimate it to be assuming around 10% evaporation.

Once the wort is up to a boil I usually skim some of the grey scum off the top. To be honest I have no idea whether this is a good idea or not. I then add the 60 min hops and start a timer.

Time for a coffee so I sort out my cold extract coffee. I'm almost tempted to put some coffee in the beer but think better of it. I also get some water for the yeast boiling in a pyrex jug in the microwave covered with a saucer. I then leave this in the microwave to cool slowly as the boil progresses.

About 30 mins in I think I am losing more volume than I expected so I top up with 2L of my spare campden treated water. I then decide I've added too much so extend the boil by 15mins before adding the 15min hops. I am not worried about any extra bitterness as my preboil gravity tells me that I am going to be stronger than my original calculations here and I didn't alter my hopping.

With a little more than 15 mins left to go I add the immersion chiller to get it sanitised. You can see the fan that I use to blow some of the moisture out of the door. We have a split door so I can boil indoors if the weather isn't great. I try to do this with enough time for the boil to get going again before adding the 15 min hops and half a protofloc tablet.

The leftover hops go in a ziploc bag with as much air squeezed out as I can and then back into the freezer

At the end of boil I chill down to around 80*C and then add the zero min hops, I chopped them up today as an experiment to see if that yields more flavour. Then leave them to steep for 20-30 minutes. Once the boil is done I am careful that nothing contacts the wort or anything that I am going to put in the wort (e.g. the yeast) without being sanitised with StarSan

Once the steep is done I chill down to 18*c,stirring with the immersion chiller speeds this process up. Then leave to settle for another 20-30 mins again covering with a lid and towel to keep the flies out. At this point I get the water for the yeast down to 30*C using a water bath and then sprinkle in the yeast, remembering to give it a stir after 15 mins or so. I use the sanitised thermometer to do this

Once the wort is settled I check the tap on the FV and then drain into it from height and giving a good stir using a sanitised sirrer to aerate. I take a sample for gravity somewhere in the middle of the process. I also add the yeast mid way, rinsing the jug out with wort to get all of the yeast in there.

OG of 1044, just shy of 21 litres

Then into the brew fridge, I have the probe outside of the wort hanging on the FV handle to make sure it is actually in the fridge and set the temp on the STC100 to 17.5*C

Time to clean up, boiler to be washed making sure that the element is cleaned. Hops squeezed out and in the food waste. Grains go to a guy for his chickens so I bag that up in a bin liner as I'm out of the used feed bags he gives me. A fair amount of **** has made it into the "false bottom".

Brewlength 21L

Predicted OG 1038

Predicted FG 1009

Predicted abv 3.7%

Colour 6.9 SRM

IBU 30

2500g Mild Ale Malt

500g Flaked Barley

500g Flaked Wheat

150g Crystal

150g Carapils

Mash 66*C

1 tsp (4g gypsum)

Challenger (6.9) 60 mins

Challenger (6.9) 15 mins

Columbus (17.1) 0 mins

Yeast S04

lots of pics to follow

HLT Filled and 1/4 campden tablet added, More water, (20L) with 1/4 campden tablet ready to use in a FV, with a fresh batch of StarSan on top

Checking the alkalinity of the water. See here for a guide

0.92ml remaining, so 0.33 meq/litre x50 = 16.5 ppm CaCO3

I then calculate my water additions using the forum tool and information from United Utilities. If I am being lazy (and I usually am) I assume that my water is soft (which it will be unless we are in a drought and the source changes) and use 1tsp(~4g) gypsum in the boil and 2 tsp gypsum in the boil (~8g) for any pale ale or bitter type of thing. I would always go carefully for a dark beer as I don't have a good water profile for them.

I need 4g gypsum for the mash

8.5g gypsum, 2g salt, 2.5g epsom salts and5g CaCl for the boil. My scales aren't all that accurate at these sorts of weights so this is all "in the ballpark"

Flaked grains measured out, then in goes the crystal and carapils, finally a temp measurement showing the Mild Ale Malt

Check the water temperature is about where I want it. Check the tap on the Mash Tun (small one today) is closed (very important)

Add water to the MT and check it is where I want it in terms of temperature (I use a spreadsheet to do the calculation based on grain temp and weight and water temp and weight. In this case 73*C

Mash in, pouring and stirring is a two hands job so no pic. I pour slowly stirring well to try and avoid dough ball formation. Then give it a good stir just in case.

Then check the temperature is where I want it (66*C) put the lid on the Mash Tun and then wrap in a sleeping bag for more insulation (not shown but I'm sure you can imagine what it looks like ).

Mash for 2 hours as I have some other stuff to get on with. I then top up with hot water to stop the mash aiming to get the temp in the mid 70s. Stir and leave for another 15mins or so to let the grain bed settle down again. I then mash out.

Recirculate the first runnings until the wort is less turbid, at least so there are no bits of grain in it. I don't usually bother going for really clear wort at this stage. I use two trays from a steamer rotated round so that the holes are out of alignment to do this. Once the wort is clear enough I run the wort out, in this case into a FV but I usually run straight into the boiler for the first batch.

Once the first batch is drained out it goes into the boiler today (really not sure why I didn't run straight in). Check the hop filter is securely attached and add the boil salts before doing this. The boiler can then be switched on to get the wort heating up while I do the second batch.

I then do the second batch adding water around 80*C and leave to settle again. I then repeat the run off process described above. A few jugs worth of wort recirculated before running off.

When I have my full volume of wort in the boiler I take a preboil gravity reading to check that my hopping is going to be OK. I usually chill this down to around 30*C so that the adjustment for temperature isn't too wobbly

Today I have 1036@ 30*C so around 1039. I am going to be stronger than I was aiming for. Looking at my IBU estimate I'm happy that being a bit less bitter is going to be OK so I don't adjust. You can do this by going back to your software and adjusting the efficiency until the predicted OG is what I estimate it to be assuming around 10% evaporation.

Once the wort is up to a boil I usually skim some of the grey scum off the top. To be honest I have no idea whether this is a good idea or not. I then add the 60 min hops and start a timer.

Time for a coffee so I sort out my cold extract coffee. I'm almost tempted to put some coffee in the beer but think better of it. I also get some water for the yeast boiling in a pyrex jug in the microwave covered with a saucer. I then leave this in the microwave to cool slowly as the boil progresses.

About 30 mins in I think I am losing more volume than I expected so I top up with 2L of my spare campden treated water. I then decide I've added too much so extend the boil by 15mins before adding the 15min hops. I am not worried about any extra bitterness as my preboil gravity tells me that I am going to be stronger than my original calculations here and I didn't alter my hopping.

With a little more than 15 mins left to go I add the immersion chiller to get it sanitised. You can see the fan that I use to blow some of the moisture out of the door. We have a split door so I can boil indoors if the weather isn't great. I try to do this with enough time for the boil to get going again before adding the 15 min hops and half a protofloc tablet.

The leftover hops go in a ziploc bag with as much air squeezed out as I can and then back into the freezer

At the end of boil I chill down to around 80*C and then add the zero min hops, I chopped them up today as an experiment to see if that yields more flavour. Then leave them to steep for 20-30 minutes. Once the boil is done I am careful that nothing contacts the wort or anything that I am going to put in the wort (e.g. the yeast) without being sanitised with StarSan

Once the steep is done I chill down to 18*c,stirring with the immersion chiller speeds this process up. Then leave to settle for another 20-30 mins again covering with a lid and towel to keep the flies out. At this point I get the water for the yeast down to 30*C using a water bath and then sprinkle in the yeast, remembering to give it a stir after 15 mins or so. I use the sanitised thermometer to do this

Once the wort is settled I check the tap on the FV and then drain into it from height and giving a good stir using a sanitised sirrer to aerate. I take a sample for gravity somewhere in the middle of the process. I also add the yeast mid way, rinsing the jug out with wort to get all of the yeast in there.

OG of 1044, just shy of 21 litres

Then into the brew fridge, I have the probe outside of the wort hanging on the FV handle to make sure it is actually in the fridge and set the temp on the STC100 to 17.5*C

Time to clean up, boiler to be washed making sure that the element is cleaned. Hops squeezed out and in the food waste. Grains go to a guy for his chickens so I bag that up in a bin liner as I'm out of the used feed bags he gives me. A fair amount of **** has made it into the "false bottom".