I don't know how well this sill last, but I've upgraded my infusion mashing setup to HERMS for very little cash..

I already had:

Burco Electric Boiler

Wort Chiller

Infusion Mash tun (Bucket in a bucket style)

I've added:

5M 3/8 ID poly pipe (About ã6)

6 Quick connect hose fittings (ã1 each from B&Q)

2 10mm to 1/2 inch pipe thread adapters for my wort chiller (ã4 off ebay inc postage)

1 12V Diaphragm pump ã8 off ebay

Sprinkler head ã7 from B&Q

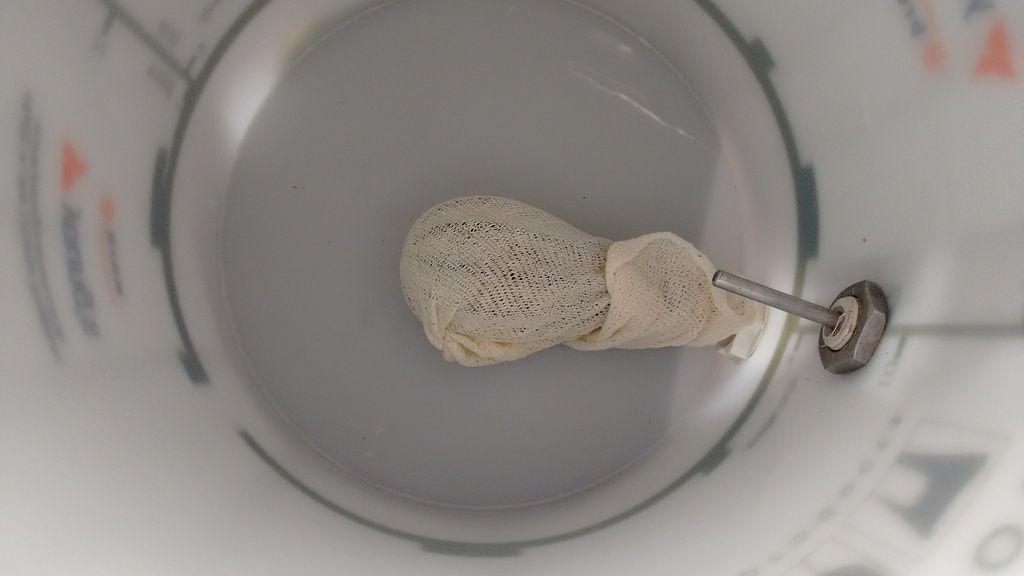

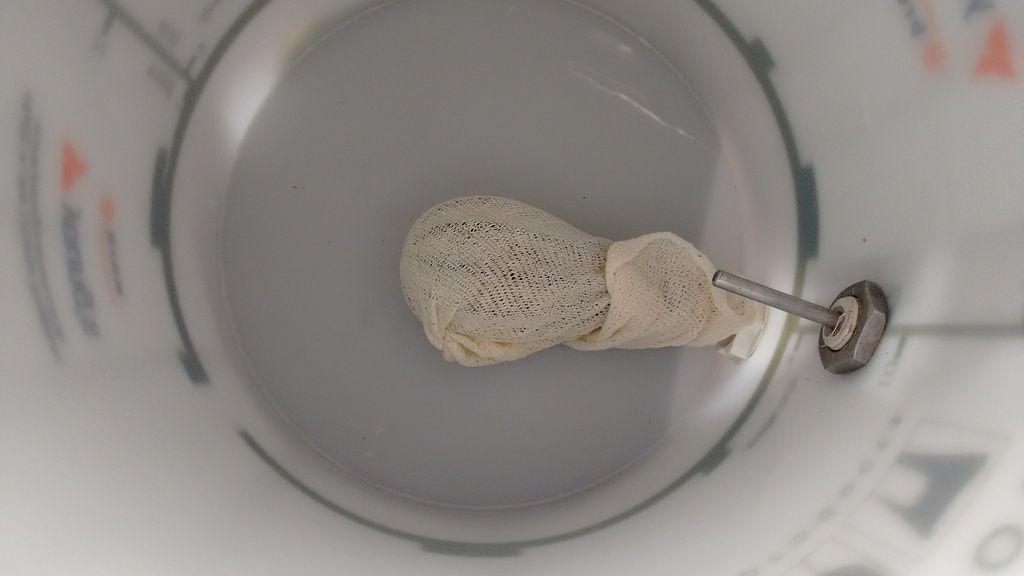

A balloon whisk and hose clip to make a simple secondary filter with my hop bag.

It seems to work well, did a dry (wet!) run earlier to get it up to temp and check for leaks, the diaphragm pump is a bit noisy but it seems to do the trick!

The idea is to use the wort chiller immersed in the boiler to control the mash temp by circulating it through it, and then dump the pump supply pipe into the boiler to sparge (Diaphragm pump can self prime)

Here's what it looks like:

The ballon whisk filter, I have a better idea for this involving a stainless shrimp filter but thats for another day:

The pipe I had lying around, its about 18mm and fits into the back of the tap nicely

I needed a decent 12V power supply, here's my solution:

All ready to go, just need to get some stuff and get a brew in!

From the test drive I have to add that the diaphragm pump is a bit noisy, if it packs in I think i'll find a centrifugal one to replace it, but it was cheap enough.

The plan is to use the boiler to control the mash temp then put the suction pipe into the boiler for sparge (Hence the long pipe). I also made some extra clip on attachments for converting the heat exchanger back to a chiller in seconds.

The thinking is that running the sparge water through the chiller will clean it, then I'll run some boiling water through everything for a few mins to help prevent any nasties from growing between brews.

I already had:

Burco Electric Boiler

Wort Chiller

Infusion Mash tun (Bucket in a bucket style)

I've added:

5M 3/8 ID poly pipe (About ã6)

6 Quick connect hose fittings (ã1 each from B&Q)

2 10mm to 1/2 inch pipe thread adapters for my wort chiller (ã4 off ebay inc postage)

1 12V Diaphragm pump ã8 off ebay

Sprinkler head ã7 from B&Q

A balloon whisk and hose clip to make a simple secondary filter with my hop bag.

It seems to work well, did a dry (wet!) run earlier to get it up to temp and check for leaks, the diaphragm pump is a bit noisy but it seems to do the trick!

The idea is to use the wort chiller immersed in the boiler to control the mash temp by circulating it through it, and then dump the pump supply pipe into the boiler to sparge (Diaphragm pump can self prime)

Here's what it looks like:

The ballon whisk filter, I have a better idea for this involving a stainless shrimp filter but thats for another day:

The pipe I had lying around, its about 18mm and fits into the back of the tap nicely

I needed a decent 12V power supply, here's my solution:

All ready to go, just need to get some stuff and get a brew in!

From the test drive I have to add that the diaphragm pump is a bit noisy, if it packs in I think i'll find a centrifugal one to replace it, but it was cheap enough.

The plan is to use the boiler to control the mash temp then put the suction pipe into the boiler for sparge (Hence the long pipe). I also made some extra clip on attachments for converting the heat exchanger back to a chiller in seconds.

The thinking is that running the sparge water through the chiller will clean it, then I'll run some boiling water through everything for a few mins to help prevent any nasties from growing between brews.