If the question is simply "I have only one sensor, where am I best to put it" then as an engineer, I would say the following:

- A fermentation fridge is effectively a closed loop control system like any others (car steering, car suspension, aircraft controls, quad-copter drone control) and the more points of measurement you use, the better you can tune the system response.

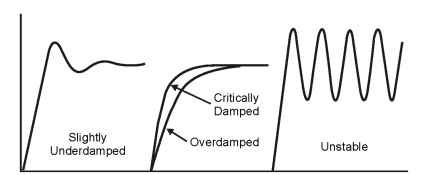

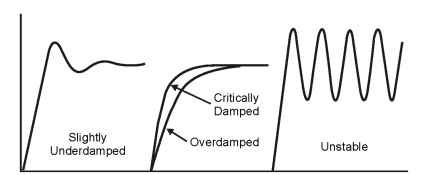

- If you ONLY measure the air temperature, then you will get a very slow system response, but it will provide you with a good stable system when on condition. To explain this more clearly, imagine you have a wort temperature of 30 deg C (just out of the copper) and you want it to reach 19 deg C. If your control system measures air temperature, then your fridge will only ever get down to 19 deg, and will therefore asymptoticly reach the target value, very slowly (like the graph below). The system has no ability to force the fridge to a lower temperature (say 10 deg C) to speed up the cooling from 30 deg C to 19 deg C, because it doesn't ever know what temperature the wort actually is.

- If you ONLY measure the wort temperature, then you can have much faster system responses, but this can lead to problems of overshoots in the desired temperature, owing to the thermal inertial of the wort. Imagine the same scenario as above. The wort is at 30 deg C and you are measuring this temperature. The fridge will turn on and be permanently on until the wort reaches 19 deg C. This means that the air temperature of the fridge can get as low as it can (if you use a freezer, it could get really low) and you can get quite a fast system response. However, when the wort does measure 19 deg C, the chances are, that some of the fluid (e.g. at the surface) is actually quite a lot colder that the measured value, and the average temperature of the wort will undershoot the target value. This will turn on the heater and you will get a cyclic undershoot and overshoot characteristic. Depending on the system, this may damp out over time (as shown by the "slightly under damped" curve below), or may remain unstable for the duration of the fermentation (as shown by the "unstable" curve below). Of course, you won't see this happening, because you are only measuring one tiny point within the fluid, but it is happening.

So, it sounds from this, that the best solution would be to first measure the wort temperature until it is "on condition" and then swap to the air temperature for a stable environment. However, there are other things to consider. For example, if you are heating the system, then do you really want your greenhouse heater to be on fully and heating the air-temperature unconstrained? Could you get to an extreme temperature that might damage the inside of the fridge or cause hot-spots in the wort that are not ideal for the yeast (albeit there will be a good amount of convection within the FV so this is unlikely to be a problem under normal conditions).

All of this, is why I measure both air and wort temperature (I should really measure wort temperature in more than one place, but don't). I effectively use a control law that measures the difference between the target wort temperature and the actual wort temperature (which is called the "error signal") and then drives a target air temperature based upon a multiplication of this error signal (with the max difference in air temp being limited to stop freezing or heating damage). This gives a fast response for a desired change in temperature (e.g. crash-cool), but a slow and stable response during steady-state conditions. The best of both worlds!

I hope all this clears up the debate :lol: