Springer

Its a dogs life

- Joined

- Oct 9, 2009

- Messages

- 1,445

- Reaction score

- 0

Hi all,

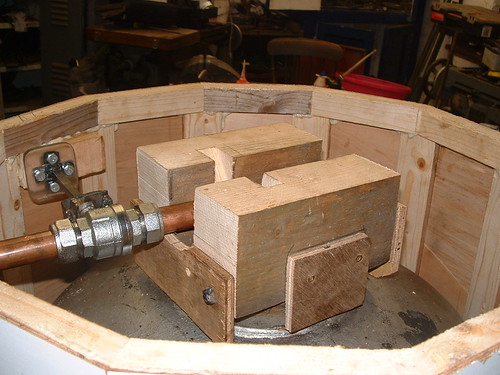

am in the process of constructing a mash tun for a gravity / herms brewery, 15 + gallons capacity. The pic shows the progress so far, dia is 450 mm and height to top of dished end is 150mm. The tun is one end that I cut from a big industrial vessel the other end will be the boiler, which is also under construction, but I think I know where I'm going with that, once I decide on gas or electric heating or both.

I Know its not shiney, the inside is, would be if someone had not painted it. It going to be well lagged, like I get sometimes, so the looks don't matter to me. :lol:

Also a quick pic of the insulation jacket, to keep the rock wool in order.

The question is what sort of strainer / false floor do I need ??

I have in mind to make a floor similar to a smaller one I made some time ago for my boiler, and then have a copper tube set up, below the floor, like the ones we do in picnic boxes.

Will this idea do the job and if so is aluminium ok or even polycarbonate, stainless is available , but is it needed, because it is so much harder to work.

, but is it needed, because it is so much harder to work.

Your thoughts would be appreciated.

am in the process of constructing a mash tun for a gravity / herms brewery, 15 + gallons capacity. The pic shows the progress so far, dia is 450 mm and height to top of dished end is 150mm. The tun is one end that I cut from a big industrial vessel the other end will be the boiler, which is also under construction, but I think I know where I'm going with that, once I decide on gas or electric heating or both.

I Know its not shiney, the inside is, would be if someone had not painted it. It going to be well lagged, like I get sometimes, so the looks don't matter to me. :lol:

Also a quick pic of the insulation jacket, to keep the rock wool in order.

The question is what sort of strainer / false floor do I need ??

I have in mind to make a floor similar to a smaller one I made some time ago for my boiler, and then have a copper tube set up, below the floor, like the ones we do in picnic boxes.

Will this idea do the job and if so is aluminium ok or even polycarbonate, stainless is available

Your thoughts would be appreciated.