Lots of comments coming in, I was thinking along the same lines as V, there are lots of ways of doing it, but looks a bit complicated to me as BB mentioned

Not studied your design in great detail, but how do you get the hot water out of the HLT, without putting cold in , or is that four pumps I count :)

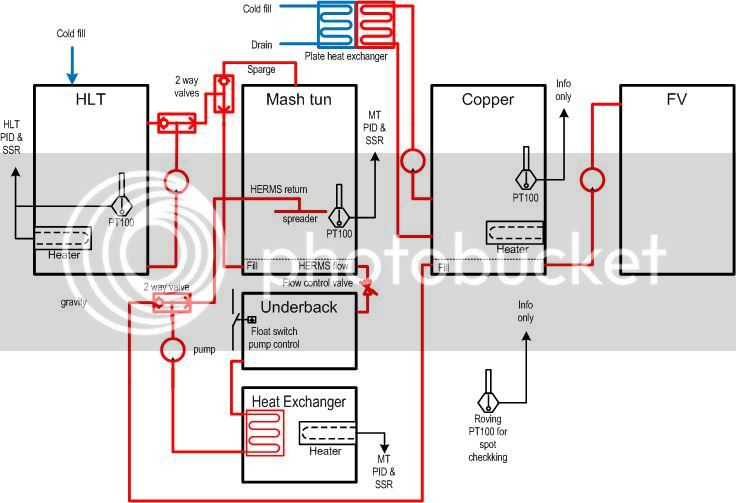

Everyone to their own but here is a pic of my set up, as I said many ways of doing it.

It is all loose piped with quick release fitting. One pump, hoses are moved as required, for brewing and cleaning.

For cleaning, very important as we all know, water goes into mash tun and can be pumped to boiler.

Cooler is a counter flow device, this and the HE can be linked together and cleaner and rinse pumped thought to pair.

A pump by-pass is essential to control flow rate.

Happy designing and brewing

Nice drawing by the way.

S