loady

[Superlative Сasual Dating Real Women]

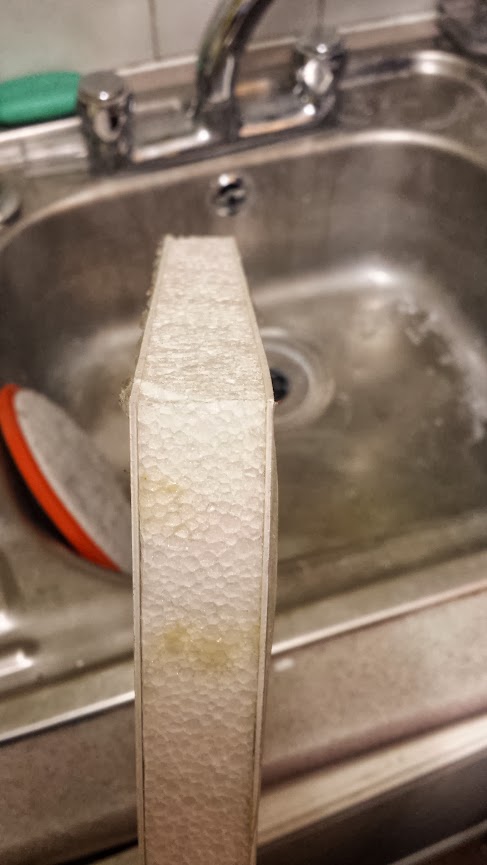

I have finished my coke fridge conversion. I removed the glass from one door and have replaced it with Upvc infill panel cut to size, it is basically polystyrene sandwich between upvc, the problem i have is that the taps thread does not stick out far enough to get the back nut on, i got around this on my previous kegerator by drilling an over sized hole on the inner hole inside the fridge door, it worked well as the front side of the door was double skinned steel, i cant do this with upvc becasue it will be to weak and will compromise the overall rigidity...are there ways to extend the tap thread or does anyone have any ideas ??