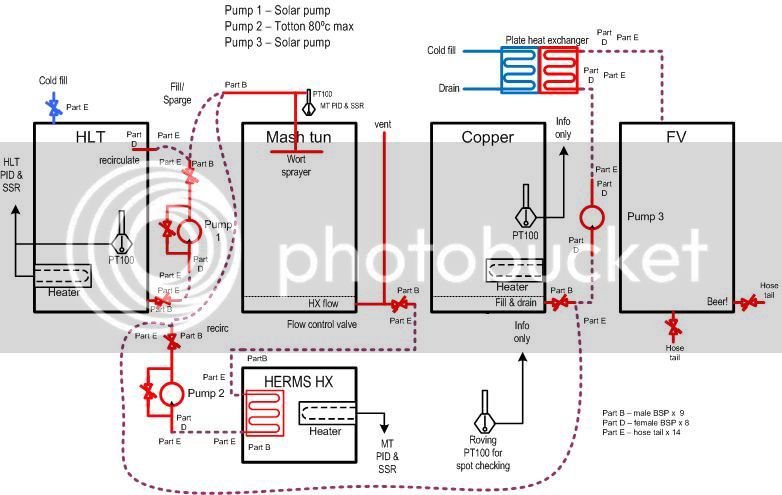

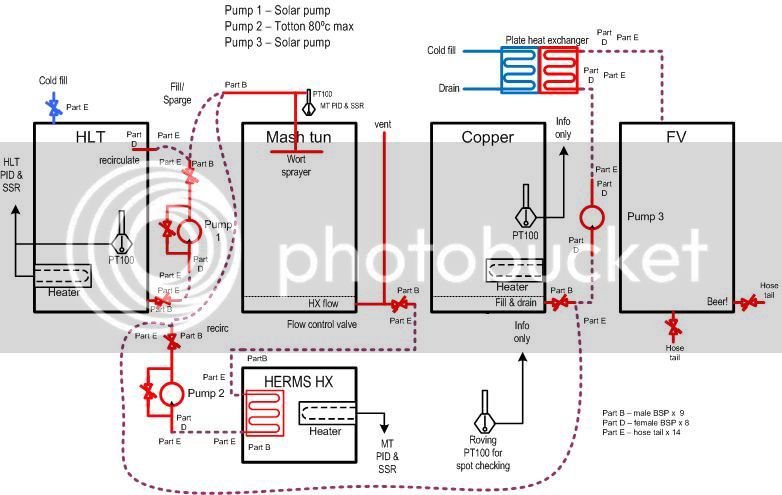

Thanks for the comments and encouragements guys! Finally managed to brew, however it was nip and tuck and I had to cut a few corners and made a few mistakes. As I had a couple of mates over for a brew weekend then the pressure was on to do more than just commission the brewery but to make some beer too. Here's the schematic of the brewery that we tried to commission, we ended up doing most of this except the recirc on the HLT to avoid stratification, the spoon was used for this and I may stick with it.

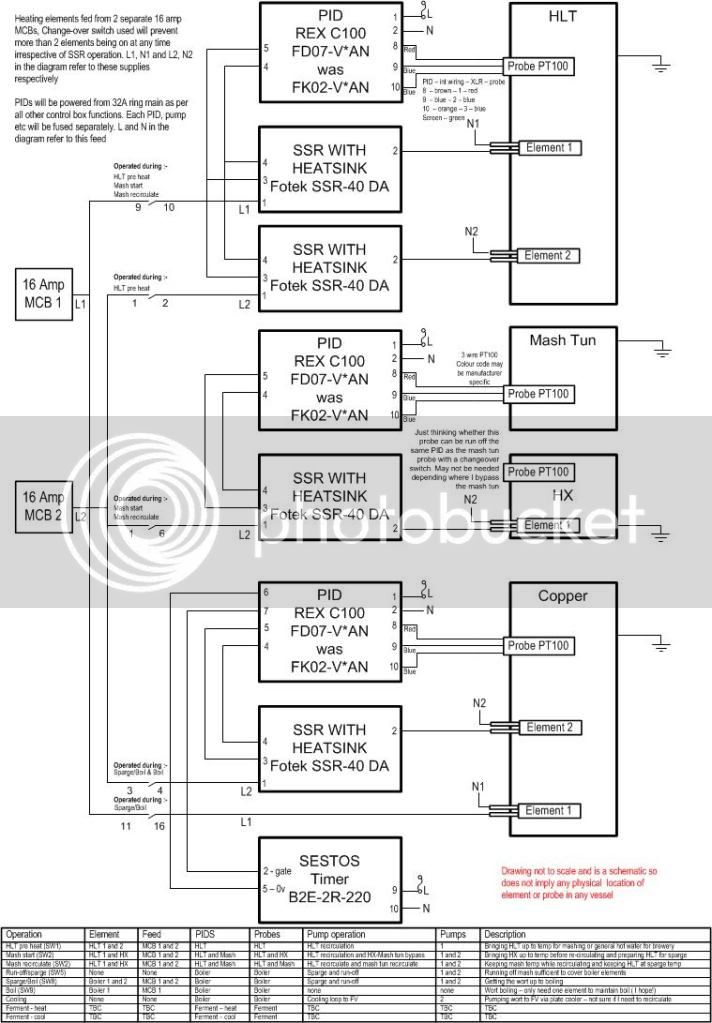

Here's the wiring diagram for the elements and control box in general. Worked a treat, only one polarity error on the PIDs that was quickly spotted and fixed and everything else worked, all 5 PIDS and probes, all 4 SSRs and all 5 elements. The big rotary switch that prevents more than 2 elements being turned on simultaneosuly also worked fine. I haven't wired in the mains LEDs to show which elements are receiving power yet however I haven't intergrated pump control yet and that is the next step. We used extension leads and and various heath robinson floating connectors (sometimes literally

) for the pumps and I need to get this sorted for next time.

Here's the quiet before the storm, control box on the wall but no vessels in. I completed the wiring for the 2 x 15 amp supllies for the elements back to MCB on the consumer unit but the PIDs etc. in the control box are using an extension lead as I haven't completed the ring main.

Here's the pump bypass assembly, possible room for improvement here. The timber the Totton pump stands on is temporary. I put a 15mm air bleed valve in the end of one of the tees which worked well to prime the pump, found the pump was very sensitive to a bit of air in the pipes and needed frequent bleeding when swapping pipes or I stood on a hose. For this first brew I got away with the Totton pump with bypass and a solar pump without. Need to complete a bypass on my other solar pump and buy some more silicon hose. Camlock connectors worked well but the rings on the end of the arms can be annoying.

Here's the temporary FV stand - will be building an insulated stand/cupboard for the next brew. This brew is using a submerged 50W SS aquarium heater set to 20c and a large duvet, the ambient temp in the brewery is 12c and the temp in the FV before the duvet went on was 17c so I think we will get away with it this time.

Here's the control box turned on and working - the extension lead is temporary. Haven't really got to grips with the timer yet except changing the display from milli-seconds to seconds.

Here's the brewery with all the pots and pumps.

Problems :-

1.) Not enough silicon pipe - need another 9m. Suffered from kinked garden hose syndrome on the plate HX water output.

2.) Wort sprayer seemed to dribble rather than spray at sparge/recirc flow rates. However I did not calibrate the flow exactly so may just need tuning. (using a brass version of a wort aerator)

3.) Plate heat exchange wort output was about 27c. had to liquor back so problem solved for this brew - may need a bigger or another HX.

4.) Spent zero time sanity checking the recipe and ended up with 80L of 1066 OG after liquoring back from 60L. In retrospect this was pretty obvious however my objective was to get a working brewery and some ale to tide me over until I get more time to do a proper job.

5.) Something to hold the plate heat exchanger in place, nearly fell onto the floor on several occasions.

6.) ceramic airstone received in lieu of the SS one wasn't 1/4" fitting - never noticed until I needed it.

Must do better next time

1.) Calibration of dead space and recirc flow rates

2.) Cleaning/sanitation routine - currently none existent. Will have to go back into the brewery and give it a good clean today and clean all the pots again.

3.) Clean buckets for spillages, cleaning and draining, buy a mop before SWMBO complains and some proper containers for large quantities of grain, both for storage and for doughing in

4.) Need to wall mount the 5L container full of RO water and starsan so its easy to dispense. Also get a spray bottle.

5.) Pay attention to the recipe a bit more!

Next steps

1.) build a FV stand/cupboard

2.) get regulators and gas for 2 x cornies

3.) Finish off pump holders and insulate all vessels

4.) Add hooks to wall to hang pipes on when not in use

5.) finish off ring main

6.) complete vent/extractor system for copper.

Cheers NB