guyb

Regular.

Ok, I have been brewing for a few years and have taken the plunge from kits, to AG a while ago.

I got fed up with having a load of glass bottles about the place and the labour that is bottling.

So having had my birthday, I decided to invest in a Corny, a regulator (single stage twin gauge), a cobra style tap (quick disconnect to a plastic affair) and I pick up my beer gas for £18 (no deposit) on thursday.

I am going to test the corny for leaks, although it was shipped pressurised etc.

I have a dilemma in that I've read a number of posts that talk about the length of beer line, volumes, psi and all manner of things.

I have 22litres of St Peters Ruby Red Ale (I don't always have time for AG) that is in a secondary for settling.

Having not used the Corny before, I am a little concerned about dumping 19L of this brew into the Corny only for me to make a mistake and end up with 19L of drain feed.

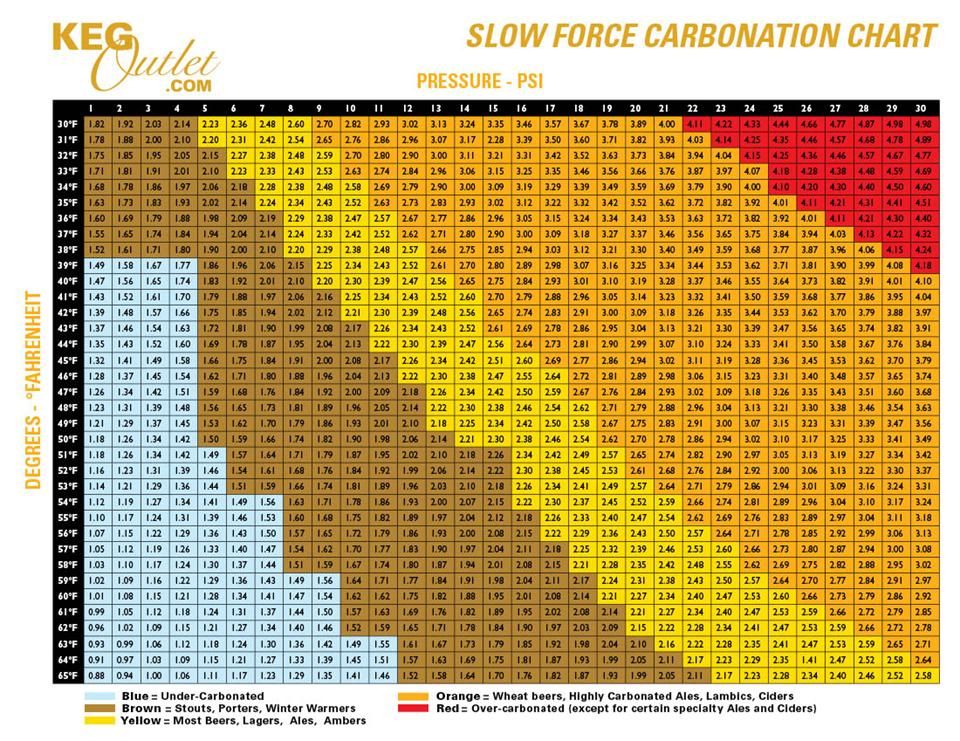

I was wondering if I could say put 5L of St Peters in to the Corny and bottle the rest, and put the Corny under pressure at say about 5.5deg c (in the fridge) and put in 13.5 psi? i.e. is there any minimum volume?

I picked up the detail about volumes and temps from here linky

I've got the "flexi tap + out disconnect" which looks to be about 1M in length in 5/8", and I also got a 2M length of 5/8" for the gas.

I've looked at the links for sterilising a corny etc in the how to section.

Any help or advice gratefully received.

I got fed up with having a load of glass bottles about the place and the labour that is bottling.

So having had my birthday, I decided to invest in a Corny, a regulator (single stage twin gauge), a cobra style tap (quick disconnect to a plastic affair) and I pick up my beer gas for £18 (no deposit) on thursday.

I am going to test the corny for leaks, although it was shipped pressurised etc.

I have a dilemma in that I've read a number of posts that talk about the length of beer line, volumes, psi and all manner of things.

I have 22litres of St Peters Ruby Red Ale (I don't always have time for AG) that is in a secondary for settling.

Having not used the Corny before, I am a little concerned about dumping 19L of this brew into the Corny only for me to make a mistake and end up with 19L of drain feed.

I was wondering if I could say put 5L of St Peters in to the Corny and bottle the rest, and put the Corny under pressure at say about 5.5deg c (in the fridge) and put in 13.5 psi? i.e. is there any minimum volume?

I picked up the detail about volumes and temps from here linky

I've got the "flexi tap + out disconnect" which looks to be about 1M in length in 5/8", and I also got a 2M length of 5/8" for the gas.

I've looked at the links for sterilising a corny etc in the how to section.

Any help or advice gratefully received.