You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

First attempt at Scrumpy!

- Thread starter falafael

- Start date

Help Support The Homebrew Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

ok, i have been down to the place and placed the apples in the industrial fridge as can be seen below, some are out of shot, but you can see the apples!!

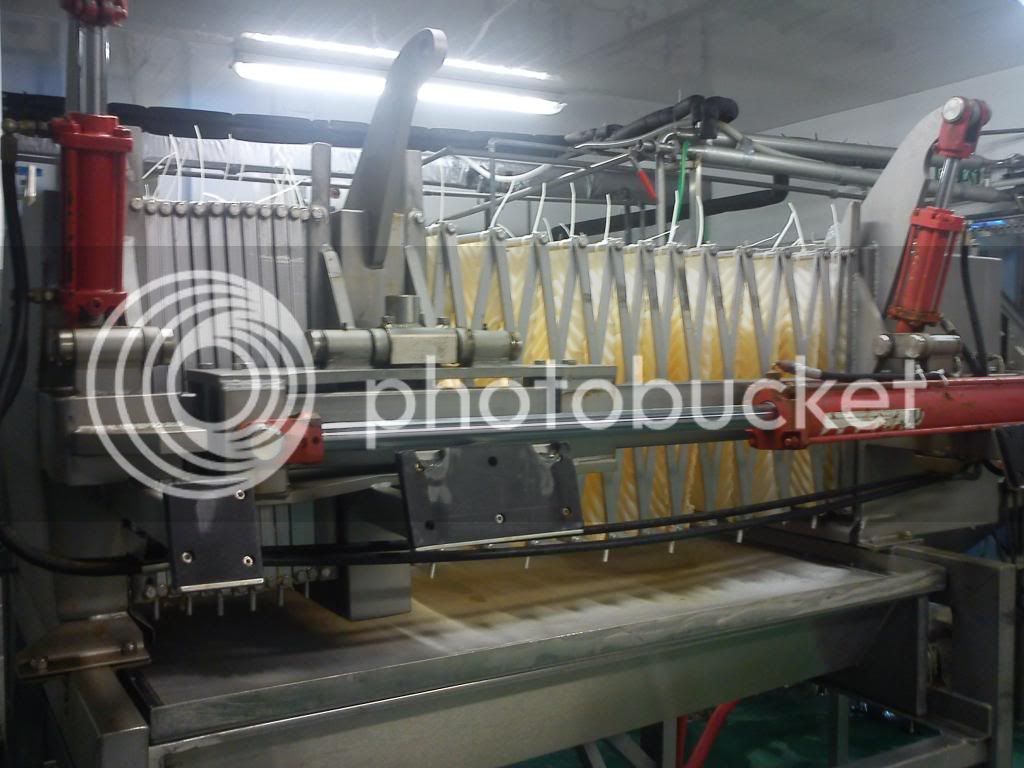

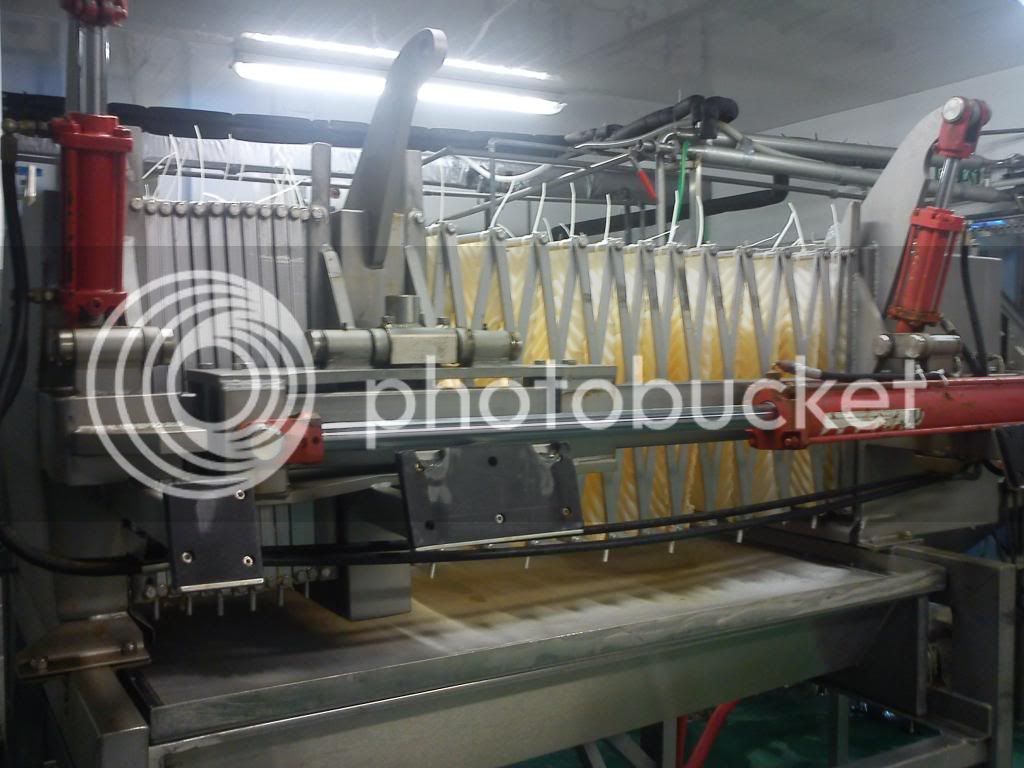

And here, is the press that is going to be squeezing the juice for us!, bit different to the normal routine, and that will squeeze every last drop too!!

More pictures tomorrow of the apples going through their motions!!

Thanks

And yes, a bit different to the normal way, but hey, after the shed, i have to try and uphold it!! LOL

And here, is the press that is going to be squeezing the juice for us!, bit different to the normal routine, and that will squeeze every last drop too!!

More pictures tomorrow of the apples going through their motions!!

Thanks

And yes, a bit different to the normal way, but hey, after the shed, i have to try and uphold it!! LOL

hypnoticmonkey

Landlord.

Wow!

I remember when I went to the Cornish Cyder Farm in... er... Cornwall, they showed their juice extraction methods. It involved pulping and then running round a massive belt thing using a concept akin to a spin drier. The pulp came out dry like carboard!

I remember when I went to the Cornish Cyder Farm in... er... Cornwall, they showed their juice extraction methods. It involved pulping and then running round a massive belt thing using a concept akin to a spin drier. The pulp came out dry like carboard!

They recommend about a week in storage, mines been just under, its so the sugars can form more, and thus more juice, but keep a eye on them, i have had to sort them, and lost 2 buckets worth, but not a lot considering how much i do have!

evanvine

Landlord.

Bulmers don't bother sorting them.

Out of the lorry/trailer and into the crusher!

Out of the lorry/trailer and into the crusher!

Bulmers jim, thats commercial *****!

Steam brew

Well-Known Member

- Joined

- Apr 8, 2013

- Messages

- 174

- Reaction score

- 0

Love the press is it a La- Caen (French) that has the course weave cloths that are used for cider ( fine for wine and olive oil ) after you press do you test the PH as well as the SG are you going the natural way to ferment (no yeast) as your crab apples will give you all the ferment you need : If a apple floats use it if it sinks bin it

If a apple floats use it if it sinks bin it

If a apple floats use it if it sinks bin it

If a apple floats use it if it sinks bin itWell, i was up at 7am, ready to start on the cider mission!

and here is how we did it!!

First of all, the apples were placed in the 'bath'!

They are then checked on the inspection belt!

Then they fall into the pulp/mincer, as you can see, it minces it really fine!!!!

We then pump the pulp up to the press, and it goes into bags to be pressed!

Then that lovely juice starts flowing!!!!

As you can see, the pulp when pressed is very dry!!!!

And then we have the juice, ready to go in the barrels!!!

And there you have it, the whole process took just under 40 minutes, and thats from the first apple, to the last drop of juice into the barrel.

We ended up with 264 litres!

Hope you like the pics!

and here is how we did it!!

First of all, the apples were placed in the 'bath'!

They are then checked on the inspection belt!

Then they fall into the pulp/mincer, as you can see, it minces it really fine!!!!

We then pump the pulp up to the press, and it goes into bags to be pressed!

Then that lovely juice starts flowing!!!!

As you can see, the pulp when pressed is very dry!!!!

And then we have the juice, ready to go in the barrels!!!

And there you have it, the whole process took just under 40 minutes, and thats from the first apple, to the last drop of juice into the barrel.

We ended up with 264 litres!

Hope you like the pics!

BigYin

Regular.

264 litres :shock: That's a lot of scrumpy :lol: :mrgreen: :

calumscott

Regular.

- Joined

- Sep 12, 2011

- Messages

- 311

- Reaction score

- 32

Bagsie I'm not washing the bottles... :lol:

hypnoticmonkey

Landlord.

Falafael, how did you get access to such a machine? Do you work for the company that owns it?

I used to work there, bout 18 year ago!!, but i know one of the guys that still work there...bit of an advantage i guess.....thinking of doing the same next year perhaps!!

Moving the apple juice into the house or pub shed in the morning, its in the other shed , but it's starting to get to chilly at night for fermenting!!

wow glenn top job mate ....

you have done yet another fantastic thread .. :clap: .

you dont do things by halfs do you .. :) .

im looking forward to any up dates... .

.

ill be keeping my eye on this one .... :party:

regards mick... :hat:

you have done yet another fantastic thread .. :clap: .

you dont do things by halfs do you .. :) .

im looking forward to any up dates...

ill be keeping my eye on this one .... :party:

regards mick... :hat:

Moved the barrels into the lounge in the week as getting chilly at night, at the moment, its fermenting really well, the only problem is that the wife is NOT happy with the smell , and it does smell very strong, of like a sulphur smell!!!

falafael said:Moved the barrels into the lounge in the week as getting chilly at night, at the moment, its fermenting really well, the only problem is that the wife is NOT happy with the smell , and it does smell very strong, of like a sulphur smell!!!

i cant say i blame her glenn...

i wouldnt like that in the house eather... :nono:

lets hope it gets better not so the smelly....

regards mick... :thumb:

Similar threads

- Replies

- 4

- Views

- 1K

- Replies

- 63

- Views

- 4K